10ton Industrial Tube Ice Machine

The 10-ton industrial tube ice machine makes lots of ice. It produces up to 10 tons of tube-shaped ice daily. This is perfect for industries needing steady ice production. It works well for food processing, fisheries, and other fields. The machine is strong and dependable, so it won’t break easily. It helps industries that need ice for keeping things cool and fresh.

Key Features of the Industrial Tube Ice Machine

High Production Capacity

The Industrial Tube Ice Machine makes a lot of ice daily. It can produce up to 10 tons of ice every day. This is great for industries needing large amounts of ice. Businesses like food processing, fisheries, or factories benefit from this machine. It ensures they always have enough ice to use.

In 2023, tube ice machines were worth $1.2 billion globally. By 2032, this value may grow to $2.1 billion. This shows more people need machines that make lots of ice. Depending on the model, they can make 1,300 kg to 40,000 kg of ice daily.

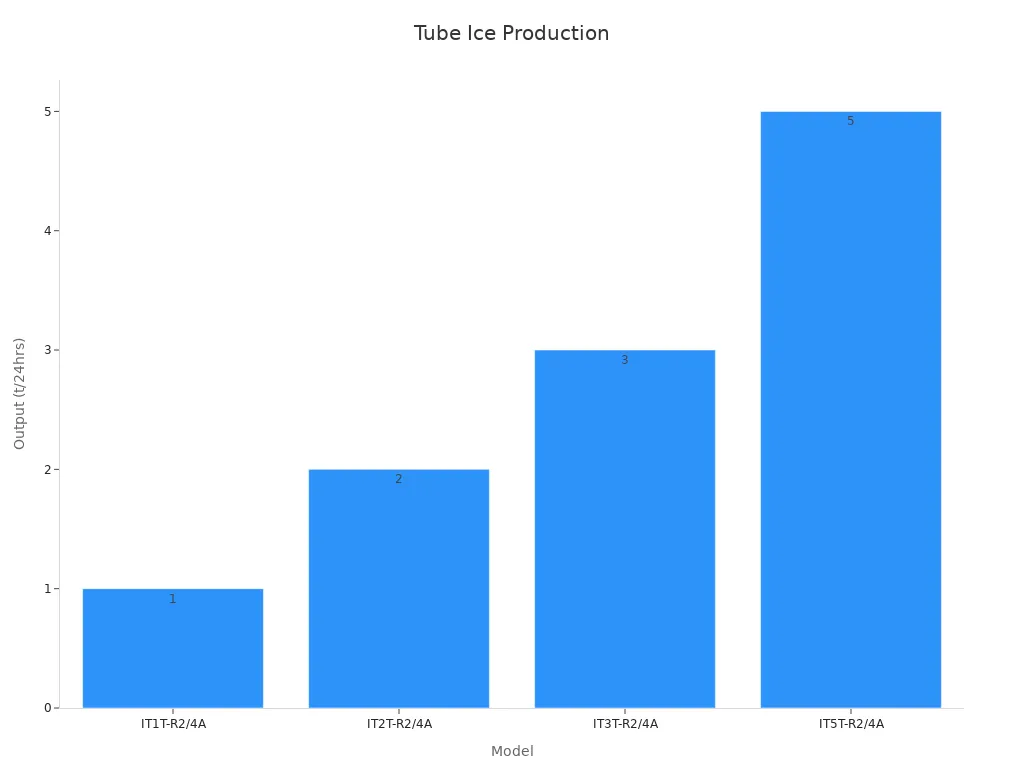

Model | Ice Output (per 24 hours) |

|---|---|

IT1T-R2/4A | 1 ton |

IT2T-R2/4A | 2 tons |

IT3T-R2/4A | 3 tons |

IT5T-R2/4A | 5 tons |

Energy Efficiency

The Industrial Tube Ice Machine uses energy wisely. It has smart technology like IoT sensors to track performance. These sensors check how well the machine cools and moves water. This helps save energy and lowers costs. Regular maintenance also keeps it running efficiently.

Energy tests show these machines meet strict energy-saving rules. They help cut electricity bills and are better for the environment. Choosing this machine means saving money and helping the planet.

Ice Quality and Consistency

This machine makes high-quality ice that is always the same. Tests show the ice is hard and melts slowly. For example:

Parameter | Specification/Standard | Notes |

|---|---|---|

Ice Hardness Measurement | Values above 100% possible if ice is cooled post phase change | Indicates latent heat capacity above 144 Btu/lb without sensible heat calculation. |

Ambient Conditions for Testing | 70 °F ±1 °F ambient air temperature; 90 °F ±1 °F initial water temperature | Ensures precise measurements. |

Good ice quality is important for food and hospitality businesses. It keeps products fresh and customers happy. This machine ensures you get the right ice every time.

Strong and Long-Lasting Build

The Industrial Tube Ice Machine is built to last. It uses tough materials to stay strong for many years. This machine works well even in tough places.

Here’s why it’s so durable:

It has certifications like ISO 9001, CE, PED, and ASME. These prove it meets top safety and quality rules.

Over 80 patents show its advanced and smart design.

Tests show it works in extreme weather, from -30°C to 50°C.

Parts resist rust, keeping the machine in good shape longer.

With care, it can work for more than 15 years.

These features make it a trusted machine in China and worldwide. Its strong build means less downtime, saving time and money. It’s great for food factories, fisheries, and cooling industries.

Buying this machine saves money by lasting a long time. You won’t need to replace it often. The Industrial Tube Ice Machine is strong, reliable, and made for big jobs.

Benefits of the Industrial Tube Ice Machine

Saving Money for Big Operations

The Industrial Tube Ice Machine helps businesses save money. Its smart design uses less electricity, cutting costs. This makes it a great choice for eco-friendly companies.

For example, a seafood company spent ¥1,000,000 on this machine. In one year, they earned ¥1,500,000 from selling ice. They saved ¥200,000 on energy and maintenance, with only ¥300,000 in operating costs. This gave them a profit of ¥400,000, a 40% return in just a year.

Using this machine lowers costs while keeping ice production high. It’s a smart and affordable option for industries needing steady ice.

Always Reliable Ice Production

This machine is very reliable and makes ice consistently. It uses advanced systems to check how well it works. These systems monitor cooling, water flow, and electrical parts.

Metric | What It Does |

|---|---|

Cooling Efficiency | Checks compressor and refrigerant flow for good cooling. |

Water Flow Performance | Tracks pump speed and filters to keep water moving. |

Electrical Stability | Watches voltage and part temperatures to avoid problems. |

Maintenance Schedule | Regular checks (like every 3 months) to keep parts working. |

Real-Time Monitoring | Finds cooling issues early so repairs can be done quickly. |

These features reduce downtime and ensure you always have ice. Whether for food or cooling, this machine works dependably.

Useful for Many Industries

The Industrial Tube Ice Machine works in many fields. It’s not just for food but also healthcare, chemicals, and construction.

Industry | How It’s Used |

|---|---|

Food and Drinks | Keeps seafood, meat, dairy, and fruits fresh. |

Healthcare | Stores blood, vaccines, organs, and lab samples at the right temperature. |

Chemical Processing | Cools reactions and stores chemicals safely. |

Construction | Helps cool concrete and speeds up building projects. |

This machine fits many needs, making it very useful. From food storage to concrete cooling, it works well in different jobs.

Environmentally Friendly Features

The 10-ton industrial tube ice machine is designed to be eco-friendly. If you want to help the planet, this machine has features for sustainability.

Energy-Saving Technology:

It uses smart parts to save electricity. The cooling system works well but uses less power. This helps lower energy bills and reduces harmful gas emissions.Eco-Friendly Refrigerants:

This machine uses new refrigerants that are safer for nature. These refrigerants have less impact on global warming and follow strict green rules.Water Recycling System:

It has a system to reuse water while making ice. This reduces waste and saves water. This is very helpful in places where water is limited.

🌱 Tip: Machines that save water can cut costs and protect nature.

Durable Materials:

The machine is made with strong materials that last long. This means fewer replacements, which reduces waste and supports green production.Compliance with Environmental Standards:

It meets tough eco-friendly rules like ISO 14001. These rules ensure the machine stays green throughout its use.

By choosing this machine, you support the environment. Its green features help nature and make your business look responsible and modern.

Applications of the Industrial Tube Ice Machine

Food Processing and Preservation

Ice is needed to keep food fresh and safe. The Industrial Tube Ice Machine makes ice that helps preserve fruits, vegetables, meat, and dairy. Its tube-shaped ice cools food evenly, stopping spoilage and keeping natural flavors. For example, in meat plants, ice slows bacteria by keeping temperatures low.

This machine helps meet food safety rules. It gives a steady ice supply to protect perishable goods. Whether for small food shops or big factories, it ensures reliable ice production for your needs.

Fisheries and Seafood Storage

Seafood must stay fresh to keep its quality. The Industrial Tube Ice Machine makes ice that keeps fish fresh after being caught. Tube ice melts slowly, keeping seafood cold for longer. This is helpful during transport and storage.

Fisheries use this machine to maintain a cold chain for their products. Tube ice stops spoilage and extends seafood shelf life. This ensures customers always get fresh, high-quality seafood.

Hospitality and Beverage Industry

Ice is important for drinks and customer satisfaction. The Industrial Tube Ice Machine makes clear ice, perfect for cocktails and drinks. Its even shape and slow melting make it great for bars and restaurants.

This machine also meets high ice demand during events or parties. It ensures enough ice for guests, even at busy times. By using this machine, you can improve service and make customers happy in your business.

Industrial Cooling and Manufacturing

The 10-ton industrial tube ice machine is important for cooling and making products. Many industries need exact temperatures to keep quality high and work smoothly. This machine gives a steady ice supply, making it very useful for cooling.

It helps cool machines and tools during production. Overheating can break machines and slow work. Tube ice removes heat well, stopping equipment from breaking. This keeps production running and avoids delays.

In chemical factories, keeping the right temperature is very important. Some reactions need specific cooling to stay safe and work properly. The tube ice machine gives steady cooling to meet these needs. Its ice is always the same, helping processes stay consistent.

💡 Did You Know?

Tube ice melts slowly, so it’s great for long cooling jobs. This means you don’t need to add ice often, saving time and effort.

Concrete makers also use this machine. Adding ice to concrete keeps it cool while it hardens. This stops cracks and makes the concrete stronger. The machine’s big ice-making ability ensures enough ice for big projects.

Industry | How Tube Ice Helps |

|---|---|

Chemical Manufacturing | Keeps reaction temperatures safe and products consistent. |

Concrete Production | Controls curing temperatures, stopping cracks and making concrete stronger. |

Equipment Cooling | Stops overheating, keeping machines working well and efficiently. |

Buying this machine improves cooling and makes work more efficient. Its many uses make it a great tool for different industries.

Maintenance and Durability

Routine Maintenance Guidelines

To keep your 10-ton industrial tube ice machine working well, regular care is needed. Follow these simple steps:

Check Weekly for Damage: Look at parts like the compressor, pump, and pipes for wear.

Clean Ice-Making Parts: Use warm water and a soft brush to remove dirt.

Monitor Refrigerant Levels: Make sure the refrigerant is at the right amount.

Lubricate Moving Parts: Add lubricant to reduce friction and avoid damage.

Inspect Electrical Wires: Ensure all wires are tight to prevent electrical problems.

🛠️ Pro Tip: Get a professional to service the machine every six months.

Tips for Extending Machine Life

You can make your machine last longer by following these tips:

Use Filtered Water: Clean water stops mineral buildup and helps the machine work better.

Don’t Overwork It: Stick to the recommended ice-making limit to avoid stress.

Keep It in a Good Spot: Place it in a cool, ventilated area with steady temperatures.

Follow Instructions: Use only parts and tools approved by the maker.

💡 Did You Know? Taking good care of your machine can add 5 extra years to its life!

Common Problems and Fixes

Even great machines can have issues sometimes. Here are some common ones and how to fix them:

Problem | Reason | Fix |

|---|---|---|

Ice Won’t Freeze | Low refrigerant or dirty coils | Refill refrigerant or clean coils |

Less Ice Made | Dirty water filters | Clean or replace the filters |

Strange Noises | Loose parts or no lubrication | Tighten parts or add lubricant |

⚠️ Note: If the problem doesn’t go away, call a trained technician to avoid more damage.

By caring for your machine and fixing problems quickly, it will work well for many years.

Cost and Return on Investment

Initial Investment and Pricing

Buying an Industrial Tube Ice Machine may seem costly at first. The price depends on its size, features, and brand. A 10-ton machine costs more because it is advanced and strong. But this cost gives you a reliable machine for making lots of ice.

You also need to think about installation costs. These include setting it up, connecting water and power, and ensuring good airflow. These extra costs are important for the machine to work well.

💡 Tip: Compare different models and check their warranties. A longer warranty can save repair costs later.

Long-Term Cost Efficiency

This machine saves money over time. Its energy-saving design lowers electricity bills each month. Its strong build means fewer repairs and replacements.

Making your own ice saves money compared to buying it. It also ensures you always have good-quality ice. Businesses like fisheries or food factories save a lot this way.

🌱 Note: Using eco-friendly refrigerants and recycling water cuts costs and helps the planet.

Calculating ROI for Businesses

To find your return on investment (ROI), calculate yearly savings. Include lower energy bills, fewer repairs, and no ice-buying costs. Subtract the machine's running costs from these savings to get your profit.

Divide your profit by the machine's cost to find your ROI percentage. For example, if you save $50,000 a year and the machine costs $100,000, your ROI is 50% in one year. This shows how fast the machine pays for itself.

📊 Example: A seafood business saved $60,000 a year by making its own ice. Their ROI was 60% in the first year.

Comparison with Other Ice Machines

Tube Ice Machines vs. Flake Ice Machines

Tube ice machines and flake ice machines make different types of ice. Tube ice is shaped like a cylinder with a hole in the middle. It melts slowly, so it’s great for drinks, seafood, and cooling industries. Flake ice is thin and flat, melting faster. It’s best for quick cooling, like in fish markets or medical storage.

Tube ice machines use less energy than flake ice machines. They save power and lower costs. Flake ice machines need more energy because they scrape ice constantly. If you want ice that lasts longer and saves energy, tube ice machines are a smarter choice.

Tube Ice Machines vs. Block Ice Machines

Block ice machines make big, solid blocks of ice. These blocks are used for shipping or long-term cooling. But they need extra steps, like cutting or crushing, to fit specific uses. Tube ice machines skip this step by making ready-to-use ice.

Tube ice machines produce ice faster and with better quality. Block ice machines take more time to freeze because of their size. If your business needs quick ice production, tube ice machines are more efficient. They also take up less space, making them easier to set up.

Unique Advantages of Tube Ice Machines

Tube ice machines are reliable and flexible. The cylindrical ice melts slower, keeping things cool longer. This makes them perfect for food, drinks, and industrial uses.

These machines are built with smart technology to save energy and protect the environment. They last a long time, cutting down on repair costs. Whether you need ice for drinks, seafood, or cooling, tube ice machines work well every time.

💡 Tip: Pick a tube ice machine for efficiency, quality, and flexibility.

The 10-ton industrial tube ice machine is special for making lots of ice, saving energy, and lasting long. It makes high-quality ice, perfect for food, fish, and drinks. This machine saves money and helps the environment by using less power. It works well in many industries and offers big savings over time. If your business needs reliable ice, this machine is a great choice for value and performance.

See Also

Important Factors When Choosing A Tube Ice Maker

Reliable Tube Ice Machine Producers You Can Depend On

Finding The Ideal Ice Machine For Your Business Requirements