How to Match Your Cooling Needs with the Right Low Temperature Chiller

Choosing the right low temperature chiller keeps your system working well. The right chiller lowers energy costs and lasts longer. For example, hybrid cooling systems often save more than full liquid ones. They use less energy and save money over time. To pick the right chiller, think about the needed temperature range, cooling power, and where it will be used. Whether you need a small chiller for exact cooling or a big one for factories, knowing these details helps you choose wisely.

Key Takeaways

Figure out how cold your application needs to be. This helps the chiller work well and save energy.

Think about how much cooling power you need. Pick a chiller that can handle the heat from your machines or tasks to prevent problems.

Check what you will use the chiller for. Different jobs, like in hospitals or factories, need different types of chillers.

Choose a chiller that uses less energy. Energy-saving chillers cost less to run and are better for the planet.

Ask an expert if you're not sure what to pick. They can help you find the right chiller for your needs.

Assessing Your Cooling Needs

Required temperature range for your application

Knowing the needed temperature range is very important. Different jobs need specific cooling levels to work well and stay safe. For example, microbial studies need exact temperatures. Psychrophiles grow best between -10°C and 15°C, while mesophiles like around 35°C.

If you work in labs or medical storage, you may need chillers that go as low as -10°C. Big factories might need chillers with wider temperature ranges for changing heat levels. Picking a chiller that matches your needs helps it work better and saves money.

Cooling capacity and load requirements

Cooling capacity shows how much heat a chiller can handle. To pick the right one, figure out how much heat your machines or process make. For example, data centers need a lot of cooling. These centers use about 40% of their energy for cooling, and a 1-megawatt center can use up to 25.5 million liters of water each year.

Liquid cooling systems, like ice bath chillers, work well in small spaces. They cut cooling loads by over 20% when using special materials called PCMs. Faster airflow can also lower cooling times by up to 25%.

Evidence Description | Numerical Evidence |

|---|---|

Discharge time decrease with temperature increase | |

Reduction in cooling loads with PCM integration | Over 20% reduction |

Yearly energy savings | Approximately 17% energy savings |

Choosing a chiller with the right cooling power keeps your system running smoothly without problems.

Application-specific considerations (e.g., industrial, medical, laboratory)

Different jobs need different types of chillers. Factories often need strong chillers that can handle lots of heat and run all the time. Medical tools, like MRI machines or vaccine storage, need exact temperatures to work safely. Labs might use ice bath chillers for steady cooling during experiments.

Saving space is also important. Liquid cooling systems let you fit more equipment in small areas, which is helpful in crowded cities.

Factor | Description |

|---|---|

Market Size | Expected to surpass USD 16.5 Billion by 2033 with an 18.56% CAGR. |

Space Optimization Needs | Essential due to constrained real estate; liquid cooling allows higher rack density than air cooling. |

Infrastructure Efficiency | Improved by liquid cooling, enabling stronger servers in compact spaces, especially in urban areas. |

By thinking about your specific needs, you can pick a chiller that works well and fits your job.

Types of Low Temperature Chillers

Air-cooled chillers: Features and ideal uses

Air-cooled chillers use air to cool systems. They are great for places with little water and need less upkeep. Their small size makes them easy to set up in tight spaces.

Industries like oil, gas, and car-making often use air-cooled chillers. They also work well for plastic molding, where exact temperatures are important.

Chiller Type | Features | Ideal Uses |

|---|---|---|

Air-Cooled Chillers | Use air to cool, fit in small spaces, easy to install | Oil and Gas, Car Industry, Steel, Plastic Molding |

If you need a chiller for small spaces or light cooling, air-cooled chillers are a smart choice.

Water-cooled chillers: Benefits and best uses

Water-cooled chillers use water to cool systems. They are more efficient and work better for big jobs. These chillers handle heavy cooling needs and run nonstop.

Water-cooled chillers work best where water is easy to get. Factories, hospitals, and data centers often pick these chillers for their steady performance. They also work well in hot places where air-cooled chillers might fail.

Type | Description |

|---|---|

Water-cooled | Uses water for cooling; works better for big jobs and hot places. |

If you need strong and steady cooling, water-cooled chillers are the way to go.

Picking between air-cooled and water-cooled chillers

Choosing between air-cooled and water-cooled chillers depends on your needs. Air-cooled chillers are simple to set up and maintain, making them good for small spaces or places with little water. Water-cooled chillers are more powerful and handle bigger cooling jobs, perfect for factories and hospitals.

Think about space, water access, and cooling needs when deciding. For labs, an ice bath chiller might be better because it’s small and precise. Ask experts to help you pick the best one for your needs.

Key Features to Look For

Energy efficiency and cost-effectiveness

Energy efficiency is very important when picking a chiller. Efficient chillers use less power and save money. They also help the environment by lowering energy use. Studies show new systems, like solar power towers, improve performance. For example:

Efficiency increased from 47.0% to 47.1%.

Cost of energy loss dropped from $3238/h to $3147/h.

These upgrades show how modern designs save energy and cut costs. For long-term savings, pick chillers with smart features. Variable speed compressors and advanced heat exchangers are good options. They improve cooling and waste less energy, making them a smart buy.

Reliability and long-term durability

Reliable chillers work without stopping, even for tough jobs. This is important for medical storage or factory work. Choose chillers made with strong materials that last a long time. Stainless steel parts resist damage and rust. Labs often use ice bath chillers because they handle hard tasks well.

Look for warranties or certifications from the maker. These show the chiller is dependable. A strong chiller reduces downtime and repair costs over time.

Maintenance and servicing requirements

Easy maintenance keeps chillers working well. Pick models with simple parts and clear instructions. Self-check systems can warn you about problems early. This saves money on repairs and helps the chiller last longer.

Water-cooled chillers need cleaning more often due to water buildup. But they are very efficient, which makes the extra work worth it. Air-cooled chillers are easier to care for and fit places with fewer resources.

Knowing how much care each type needs helps you choose wisely. Pick a chiller that matches your needs and budget.

Environmental and Operational Considerations

How temperature and climate affect chillers

The place you put a chiller affects how well it works. Hot weather can make cooling less effective. Air-cooled chillers may struggle in heat because they use air to cool. Water-cooled chillers work better in hot areas since water removes heat faster.

Cold places might need extra features like freeze protection to stop damage. Think about the usual temperature and weather changes where you live. This helps your chiller work well all year long.

Space and setup challenges

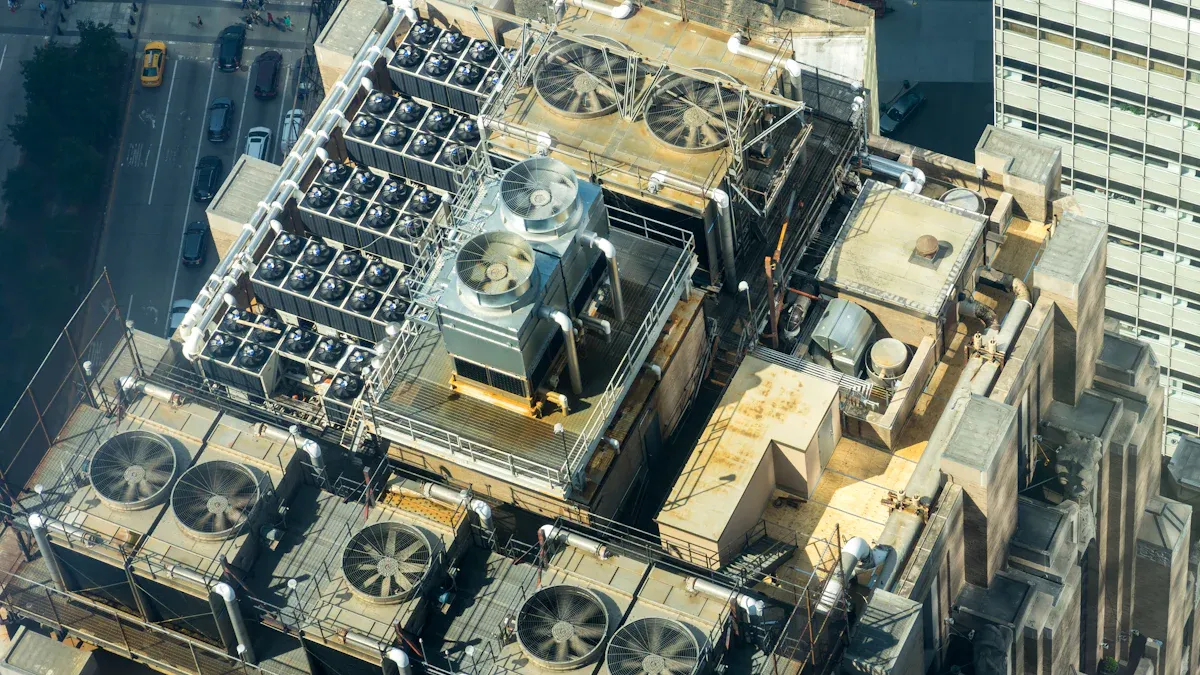

The space you have decides which chiller fits best. Air-cooled chillers are small and easy to set up, good for tight spaces. Water-cooled chillers need more room for towers and pipes.

Labs or small buildings might prefer ice bath chillers. These chillers are small and cool things exactly, saving space. Measure your area and check for obstacles before installing. Planning ahead avoids problems and makes setup easier.

Noise and working conditions

Noise matters in places like hospitals or offices. Air-cooled chillers are louder because of their fans. Water-cooled chillers are quieter, better for places needing less noise.

Think about where the chiller will be used. Dusty spots can block air-cooled chillers, lowering their performance. Cleaning helps, but picking the right chiller for your location prevents these issues.

Tips for Proper Sizing and Selection

Figuring out the right chiller size

Picking the correct chiller size helps save energy and cool better. To find the cooling load, use these formulas:

Heat Load (BTUs) = Volts x Amps x 3.412

Cooling Load (Tons) = BTUs / 12,000

These formulas show how much heat your system makes and the cooling power needed. For example, nickel plating needs exact temperatures to keep quality high. Things like outdoor weather, tank wall heat, and heat brought into the tank also affect cooling needs.

Using these calculations fully helps you include all factors. Custom chillers can meet special needs. Whether you need small portable chillers or big industrial ones, sizing them right ensures they work well.

Avoiding common mistakes when choosing

Choosing the wrong size chiller can waste energy or cause problems. A common mistake is picking a chiller too small. This makes it work too hard and break often. Picking one too big wastes energy and costs more to run.

Another mistake is forgetting about the environment. Outdoor chillers must handle changing weather. Ignoring this can shorten their life. Skipping maintenance can also cause sudden breakdowns.

To avoid these issues, think carefully about your cooling needs. Look at the job, where it will be used, and what features are needed. Planning well helps you pick the best chiller and avoid errors.

Asking experts for advice

If unsure, ask experts for help. They can check your cooling needs and suggest the best chiller. Experts look at cooling load, temperature needs, and weather to give good advice.

For example, if you need a portable water chiller for a short job, an expert can help you pick the right one. They can also explain tricky calculations and make sure your system follows rules. Getting expert advice helps you avoid mistakes and saves money.

Tip: Always pick a chiller that fits your goals. Expert help ensures you choose wisely and save energy long-term.

Picking the right low temperature chiller helps your system work well. Knowing your cooling needs avoids errors and saves energy. Choosing wisely also keeps your equipment running longer with fewer problems.

Tip: Follow a step-by-step plan. Check your cooling needs, look at choices, and ask experts for help. This helps you pick a chiller that works well and costs less.

The right chiller gives better cooling, saves money, and lasts longer.

FAQ

What is the best temperature range for low temperature chillers?

The best range depends on what you need. Medical storage chillers usually work between -10°C and 4°C. Factories might need chillers with bigger ranges. Always pick a chiller that fits your cooling needs.

How do low temperature chillers help cold therapy?

Low temperature chillers keep cooling steady for cold therapy. They hold exact temperatures, which helps reduce swelling and recover after workouts. This accuracy makes treatments work better.

Are air-cooled chillers good for tight spaces?

Yes, air-cooled chillers are small and simple to set up. They fit well in small areas and need little care. But they might not work as well in very hot places.

How often should you check a low temperature chiller?

How often depends on the type of chiller. Air-cooled chillers need less care, while water-cooled ones need cleaning to stop buildup. Follow the maker's rules to keep it working well.

Can low temperature chillers handle changing weather?

Yes, many chillers can adjust to different weather. Water-cooled chillers work better in hot places. Air-cooled chillers might need extra parts like heat exchangers to stay steady.

See Also

Maximizing Efficiency in Your Walk-In Chiller System

Enhancing Performance of Chillers and Compressors in ARKREF Units

Essential Strategies for Effective Cold Room Temperature Management