Why cold storage always beats old-school warehousing

You get better results when you use cold storage instead of a warehouse. Products stay fresh because you can set the temperature in cold storage. Customers want better quality and will pay more for it. Profits go up as more people want your products stored in cold storage.

Tip: Cold storage helps your business grow and change for the future.

Cold Storage Advantages

Product Quality

You want your products to stay fresh and safe. Cold storage lets you pick the best temperature for each item. This helps fruits, vegetables, dairy, and medicine last longer. They also taste better. Studies show cold storage keeps grapes good for weeks. The table below shows how packaging and cold storage help grapes stay fresh and lose less weight:

Study Title | Key Findings |

|---|---|

Quality loss of minimally processed grapes as affected by film packaging | Nonperforated polypropylene packages kept grapes tasting better than control grapes after 18 days in cold storage. |

Effects of modified atmosphere packaging on quality parameters of minimally processed table grapes during cold storage | Microperforated polypropylene packages helped grapes lose less weight and decay less in 14 days of cold storage. |

Effects of passive and active modified atmosphere packaging conditions on quality parameters of minimally processed table grapes during cold storage | Polypropylene packaging kept grapes fresher than polyethylene, which made grapes rot faster. |

Effects of modified atmosphere packing and honey dip treatments on quality maintenance of minimally processed grape cv. Razaki | MAP and honey dip helped grapes lose less weight and stay fresh at 0°C in cold storage. |

Tip: You can use cold storage to keep food and medicine safe for a longer time.

Market Demand

More businesses need cold storage every year. Food companies and drug makers want better ways to keep products cold. People want fresh food and safe medicine, so cold storage is more popular. Here are some market trends:

We Store Frozen helps small and medium food businesses. This shows more people want custom cold storage.

Blue Barrel Tequila grew from two pallets to selling nationwide with cold storage.

Flexible cold storage is now very popular in the food business.

Note: Cold storage helps businesses grow by meeting the need for safe, high-quality products.

Compliance

You must follow strict rules in cold storage. These rules keep customers safe and protect products. Groups like the FDA and USDA make rules for temperature and safety. The table below lists important rules:

Regulatory Body | Primary Focus | Key Requirement Example |

|---|---|---|

FDA (Food and Drug Administration) | Food, drugs, and biologics safety. | FSMA rules require controls and tracking. |

USDA (U.S. Department of Agriculture) | Meat, poultry, and eggs. | Needs special temperature rules for processing and shipping. |

HACCP | Preventing hazards in food making. | Checks and watches key points like fridge temperatures. |

NSF International | Health rules for equipment and materials. | Makes sure prep tables are easy to clean and don’t soak up liquids. |

Alert: You need to keep records and check temperatures to follow the rules.

Efficiency

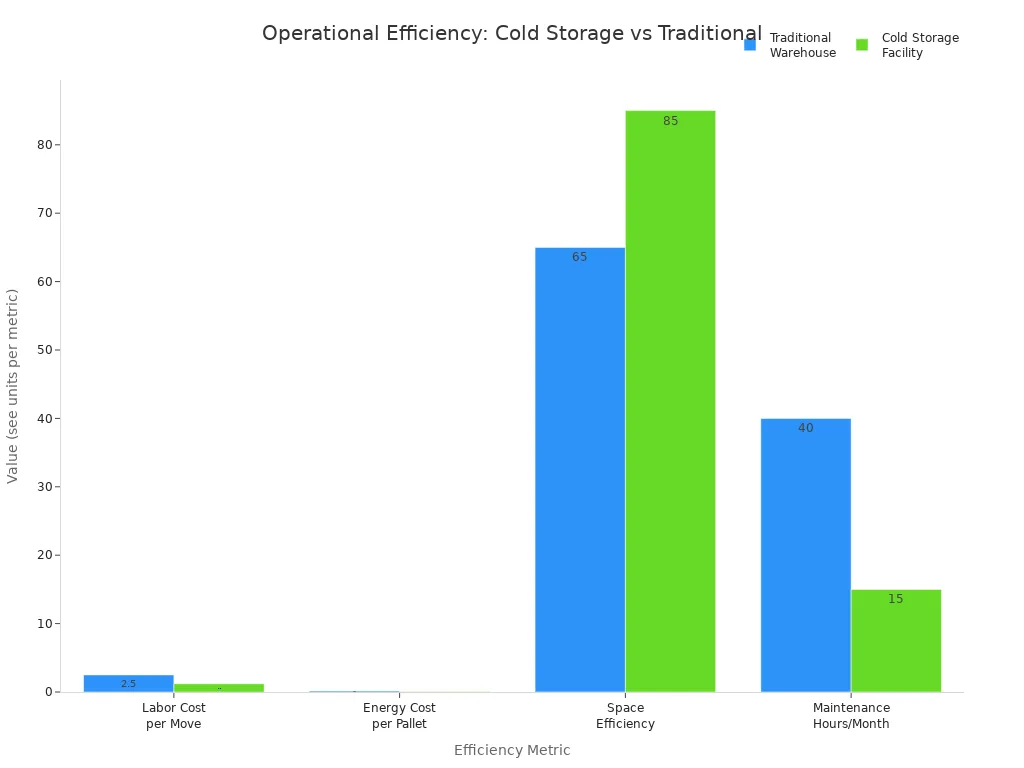

Cold storage saves money and time compared to regular warehouses. Cold storage uses less energy for each pallet and needs less fixing. You also get more room for your products. The table below compares important numbers:

Metric | Traditional Warehouse | Cold Storage Facility | Difference |

|---|---|---|---|

Labor Cost per Move | $2.50 | $1.20 | 52% less money spent |

Energy Cost per Pallet | $0.15 | $0.08 | 47% less money spent |

Space Efficiency | 65% | 85% | 31% more space used well |

Maintenance Hours/Month | 40 | 15 | 63% less time fixing things |

Cold storage works better and costs less. You can store more products in less space and keep them at the right temperature.

Start a Cold Storage Facility

Market Research & Demand

You need to learn about the market first. Check if people want frozen foods, fresh produce, or medicine in your area. Many businesses need cold storage because people buy more fresh and frozen things. Food stores, biopharma companies, and online shops use cold storage to keep products safe. More people shop for groceries online, so cold storage is needed more. Biopharma companies also need more space for their products. Make sure your area has enough supply and good roads and utilities. This helps you plan for steady business and future growth.

Tip: Small and mid-sized food businesses often need flexible cold storage. They can help your business grow.

Business Plan & Funding

You need a strong business plan. The plan should show how you will make money and what you need to spend. It should explain how you will run your cold storage. Add financial plans and steps to build your facility. Building costs can be high. Since 2022, investors have put over $200 million into cold storage to help exports and compete worldwide. You can get money from banks, private investors, or government programs. SBA loans can help you buy land or fix your warehouse. Good roads and clear rules are important for your business.

List of common startup costs and funding sources:

Land and building purchase

Building cold rooms

Refrigeration equipment

Staff training and monitoring systems

Backup power systems

Money for daily operations

Site & Commercial Cold Room Design

Pick a place with good roads and utilities. Think about planning and building your cold storage. Use insulated concrete walls or metal panels for temperature control. These materials help keep the cold in and save energy. Keeping out moisture is very important. High-efficiency insulation panels work best for meat and other foods. Hire experts to design and build your cold storage to avoid mistakes.

Best ways to design a commercial cold room:

Use high-efficiency insulation panels.

Pick energy-saving refrigeration units.

Use advanced fans for better air flow.

Use smart systems to control temperature.

Do regular checks and maintenance.

Follow food safety rules.

Licensing & Compliance

You need the right licenses before opening your cold storage. Follow rules from the FDA, USDA, and local health offices. Keep records and check temperatures often. Automated systems help you follow the rules and lower risks.

Feature | Benefit |

|---|---|

Accurate Temperature Readings | Gives up to a 9-degree more accurate reading, keeping food safe and lowering risks. |

Real-time Monitoring | 24/7 checks help keep safe temperatures and stop foodborne illnesses. |

Predictive Maintenance | Past data helps you fix things before they break, so you have less downtime. |

Labor Cost Reduction | Automatic logs save time and lower labor costs from manual checks. |

Compliance Assurance | Makes a digital log for easy inspections and following rules. |

Alert: Automated systems help you pass inspections and keep products safe.

Technology & Cold Storage Solutions

Use new cold storage technology to save money and work better. Use natural refrigerants like ammonia and CO₂ to help the environment. Automated Storage and Retrieval Systems help you use space well and need less labor. Smart control systems change cooling in real time, saving energy and stopping spoilage. Better insulation and smart building tools help control temperature. AI makes your cold storage work faster and better.

Benefits of new cold storage solutions:

Lower costs with energy-saving refrigeration

Less manual work because of automation

Faster and more accurate product handling

Less spoilage and waste

Better energy use and lower bills

Staffing & Training

You need skilled workers to run your cold storage safely. Licensed operators are needed for ammonia, CO₂, and big refrigeration plants. Experts make sure the system is safe and downtime is low. Staff must know how to check, watch, and adjust systems. Training helps your team learn the best ways to work.

Training Program | Dates | Format |

|---|---|---|

Foundation in Cold-chain | 13th October to 17th October, 2025 | In-person |

Train the Trainer | 20th October 2025 (10 x Non-consecutive weeks) | In-person |

Essentials in Cold-chain systems | 22nd October - 3rd November 2025 | Fully online - Self-paced |

GCCA Training & Education | N/A | N/A |

Benefit | Description |

|---|---|

TSSA compliance | Licensed operators are needed by law for ammonia, CO₂, and big refrigeration plants. |

Expert oversight | Operators check, watch, and adjust systems to keep them safe. |

Reduced downtime | Good management stops breakdowns and keeps things running. |

Regulatory confidence | The service handles reports, audits, and paperwork, so you can focus on your business. |

Note: Regular training helps your staff handle emergencies and new technology.

Marketing & Customers

You need to find the right customers. Food stores, biopharma companies, and online shops need cold storage. Flexible services attract small and mid-sized businesses. Show how your cold storage keeps products safe and fresh. Talk about your temperature controlled warehousing and reliable cold storage. Use online ads, trade shows, and local business groups to get new customers.

Main customer groups:

Food retailers

Biopharma companies

E-commerce players

Tip: Focus on growing e-grocery and biopharma storage needs to grow your business.

Operations & Maintenance

You must keep your equipment working well to stop breakdowns and keep products safe. Regular checks help you find problems early. Cleaning stops mold and bacteria. Checking refrigerant levels keeps cooling strong and saves energy. Maintenance plans help you lower bills and stop downtime.

Maintenance Task | Importance |

|---|---|

Finds wear, strange noises, and temperature changes to stop big problems. | |

Cleaning and Sanitizing | Keeps things clean and stops mold and bacteria from growing. |

Checking Refrigerant Levels | Keeps cooling strong and stops high energy use from low refrigerant. |

Benefits of regular maintenance:

Energy efficiency lowers bills

Early checks stop breakdowns

Safety checks stop leaks and electrical problems

Callout: Good maintenance keeps your warehouse running well and protects your investment.

Challenges & Solutions

Investment Costs

Starting a cold storage business costs a lot. You need money for land and buildings. You also need money for refrigeration and safety systems. Many new business owners worry about getting enough money. There are different ways to pay for these costs. The SBA 7(a) Loan helps you buy cold storage equipment. It also helps with other business needs. The table below shows the main financing option:

Financing Use | Description |

|---|---|

SBA 7(a) Loan | Can be used for legitimate business purposes, including cold storage equipment. |

Tip: You can spend less at first by picking energy-saving equipment. Plan ahead so your business can grow.

Energy Use

Cold storage needs lots of energy to keep things fresh. You must control temperature and humidity all day. High energy bills can lower your profits. Smart cooling systems and good insulation help you use less power. Automated controls save energy too. Solar panels and backup generators keep things working during power cuts. You save money and keep products safe.

Ways to use less energy:

Put in LED lights

Use compressors that save energy

Watch temperature with smart sensors

Regulations

Cold storage has many strict rules to follow. These rules keep food, medicine, and other items safe. You must keep records and check temperatures often. You also need to pass inspections. Automated systems help you follow these rules. Digital logs show inspectors you are following the rules. Training helps your staff get ready for audits.

Alert: Following all safety and health rules helps you avoid fines and shutdowns.

Supply Chain

You need a strong supply chain for your cold storage. Delays can spoil products and make customers unhappy. Work with suppliers and transport companies you trust. Tracking systems help you watch shipments and stop problems. Cold storage lets you keep products fresh longer than regular warehouses. Your business keeps moving and customers stay happy.

Steps to make your supply chain stronger:

Pick partners you trust

Use tracking that works in real time

Make plans for emergencies

Best Practices

Tech Upgrades

You can make your cold storage smarter with new tech. Smart sensors help you watch temperature and humidity. Automated systems let you control cooling and lights from your phone. This saves energy and keeps products safe. AI tools help you find problems before they get big. Cloud software lets you keep records and share updates with your team.

Tip: Upgrade your equipment every few years. This helps you stay ahead and stop breakdowns.

Popular tech upgrades for cold storage:

Smart temperature sensors

Automated storage and retrieval systems

Energy-saving compressors

Cloud-based monitoring software

Partnerships

You need strong partners to help your business grow. Work with local farmers, food companies, and shipping firms. Good partners bring steady business and fix problems fast. You can join trade groups to meet new customers and learn new things. Trusted suppliers help you get the best equipment and repairs.

Partner Type | Benefit |

|---|---|

Farmers | Fresh products, steady supply |

Food companies | Regular contracts, growth |

Shipping firms | Fast delivery, fewer delays |

Trade groups | Networking, new customers |

Note: Build trust with your partners. Good relationships help your business last.

Continuous Improvement

You should always look for ways to do better. Ask your team for ideas to make things safer and save money. Check your systems often and fix problems right away. Use feedback from customers to make your service stronger. Train your staff on new tools and safety rules.

Steps for continuous improvement:

Review your work every month.

Set clear goals for your team.

Track results and share updates.

Celebrate wins and learn from mistakes.

Callout: Small changes can make a big difference. Keep improving to stay ahead in cold storage.

Cold storage works better than old-school warehousing. Smart racking helps you use space well. Automated systems keep products fresh for longer. You can meet what customers want and waste less.

Cold storage gives your business a good chance to grow.

You should start planning your facility now.

Ask experts for help and advice.

You can build a business that is ready for the future and fits what the market wants.

See Also

Understanding Cold Storage: Its Functionality and Importance

Seven Groundbreaking Developments in Cold Storage Logistics

Comparing Container Cold Rooms and Conventional Cold Storage

Advantages of Quick Freezing Tunnels Over Warehousing Solutions