What You Need to Know About Commercial Cold Rooms

A commercial cold room is a specialized space designed to maintain precise low temperatures, ensuring the safe storage of temperature-sensitive products. These rooms play a critical role in industries like food, pharmaceuticals, and florals by preserving freshness and extending product shelf life.

Different industries require specific temperature ranges to meet their needs. For example:

Industry | Temperature Range |

|---|---|

Food | |

Pharmaceuticals | Below freezing for certain items |

Floral Storage | Varies based on specific needs |

To achieve these conditions, robust insulation and durable materials are essential. This ensures consistent temperatures and energy efficiency, even with frequent use.

Types of Commercial Cold Rooms

Walk-In Cold Rooms

Walk-in cold rooms are a popular choice for businesses that need a dedicated space for storing perishable goods. These cool rooms are designed to allow you to physically enter the storage area, making it easier to organize and access inventory. They are ideal for restaurants, supermarkets, and small-scale food processing units. You can customize the size and layout of walk-in cold rooms to fit your specific needs.

One of their key advantages is their accessibility. You can walk in and retrieve items without disrupting the overall storage system. These cold rooms often come with advanced refrigeration systems that maintain consistent temperatures, ensuring the freshness of your products. Walk-in cold rooms are also energy-efficient when properly insulated, which helps reduce operational costs.

Modular Cold Rooms

Modular cold rooms offer a flexible solution for businesses with evolving storage needs. These cool rooms are built using panels that can be easily assembled or expanded. This modular design allows you to scale up your storage capacity as your business grows.

Key features of modular cold rooms include:

Easy expansion by adding panels, making them highly scalable.

Advanced refrigeration systems that can be upgraded for better energy efficiency.

Support for technology integration, such as automated temperature monitoring.

A future-proof design that adapts to your business's changing requirements.

Modular cold rooms are perfect for businesses that anticipate growth or need temporary storage solutions. Their adaptability makes them a cost-effective choice for many industries.

Industrial Cold Rooms

Industrial cold rooms are designed for large-scale operations. These cool rooms are essential in industries like food processing, pharmaceuticals, and agriculture. They provide the high-capacity storage needed to maintain product quality and prevent spoilage.

You will find industrial cold rooms in food processing plants, where they store bulk quantities of frozen or chilled goods. They are also crucial in medical labs for preserving sensitive materials like vaccines and lab samples. Their robust design ensures they can handle heavy loads and maintain precise temperature control.

Industrial cold rooms often feature advanced insulation and powerful refrigeration systems. These features ensure consistent performance even in demanding environments. Their versatility and reliability make them a cornerstone of many industries.

Blast Freezers and Chillers

Blast freezers and chillers are essential for businesses that require rapid cooling or freezing of products. These cool rooms are designed to lower the temperature of items quickly, preserving their quality and preventing bacterial growth. You will often find them in industries like food processing, where maintaining freshness is critical.

Blast freezers work by circulating extremely cold air at high speeds. This process freezes products much faster than traditional methods. For example, seafood, meat, and baked goods benefit from this rapid freezing, as it helps retain their texture and flavor. Chillers, on the other hand, are ideal for cooling items to a specific temperature without freezing them. They are commonly used for beverages, dairy products, and pre-cooked meals.

Key advantages of blast freezers and chillers include:

Improved product quality: Rapid cooling minimizes ice crystal formation, preserving texture.

Extended shelf life: Products stay fresh for longer periods.

Versatility: Suitable for various industries, including food, pharmaceuticals, and hospitality.

These cool rooms are a valuable addition to any business that prioritizes product quality and safety.

Custom Cold Rooms

Custom cold rooms offer tailored solutions for businesses with unique storage needs. Unlike modular or industrial cold rooms, these cool rooms are designed to meet specific requirements. You can customize the size, temperature range, and features to align with your operations.

For instance, a bakery might need a cold room with precise humidity control to store dough, while a pharmaceutical company may require a room with advanced monitoring systems for vaccines. Custom cold rooms provide flexibility, ensuring your storage solution fits your exact needs.

Benefits of custom cold rooms include:

Personalized design: Tailored to your business's specifications.

Enhanced efficiency: Optimized for your specific products.

Scalability: Easily adaptable as your business grows.

Investing in a custom cold room ensures you get a solution that aligns perfectly with your operational goals.

Applications of Commercial Cold Rooms

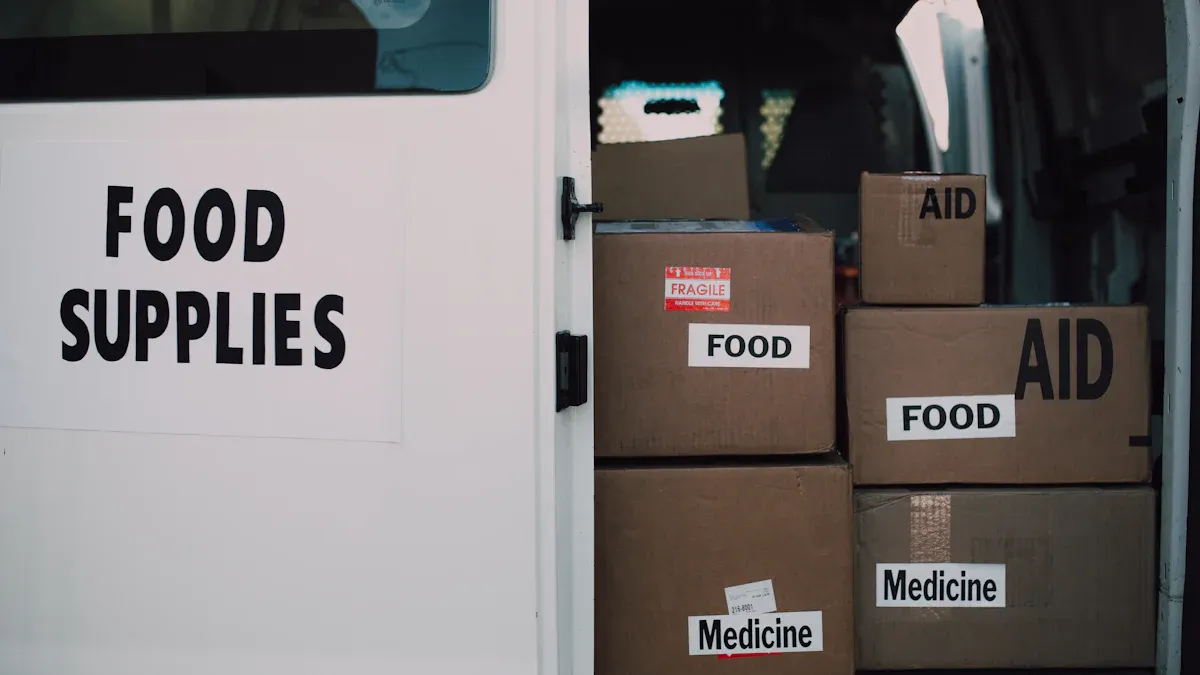

Food and Beverage Industry

Cold rooms play a vital role in the food industry by ensuring perishable items like fresh produce, meat, and dairy remain in optimal storage conditions. Proper refrigeration slows spoilage and helps maintain food safety standards. For example, walk-in cold rooms allow you to store large quantities of perishable goods while keeping them easily accessible. This is especially important for supermarkets and restaurants that need to manage inventory efficiently.

In food processing plants, industrial cold rooms are essential for preserving raw materials and finished products. These facilities rely on controlled temperature storage to prevent bacterial growth and maintain product quality. By using cold storage solutions, businesses in the food service industry can reduce waste and ensure that more food reaches consumers in fresh condition.

Pharmaceutical and Healthcare Industry

Pharmaceutical cool rooms are critical for storing vaccines, medicines, and lab samples under precise temperature control. Maintaining the correct environment ensures the potency and safety of these sensitive products. For instance, vaccines often require refrigeration between 2°C and 8°C, while some medicines need freezing temperatures as low as -15°C. The table below highlights common temperature requirements for pharmaceutical storage:

Storage Type | Temperature Range |

|---|---|

Refrigerator | 2° to 8° C |

Freezer | -15° to 0° C |

Cool | 8° to 15° C |

Ambient | 15° to 25° C |

Pharmaceutical cold rooms also help you comply with strict regulations, such as Good Manufacturing Practices (GMP). Advanced monitoring systems ensure consistent temperature control, while backup power supplies protect products during outages. These features make cold room storage indispensable for the healthcare sector.

Floral and Horticulture Industry

Flowers and plants require specialized cold storage applications to maintain their freshness and beauty. Cold rooms slow the natural aging process by reducing the metabolic rate of flowers. Lower temperatures, typically between 0°C and 5°C, help retain moisture and prevent wilting. High humidity levels (90% to 95%) further enhance preservation by minimizing bacterial growth.

Proper ventilation is another key factor. It prevents the buildup of ethylene gas, which accelerates aging. By using refrigerated space, you can extend the life of flowers by several days or even weeks. This reduces waste and improves the marketability of floral products. Whether you run a flower shop or a large horticulture business, cold storage solutions ensure your products remain vibrant and appealing.

Hospitality and Catering

Large-scale events, such as weddings, conferences, and festivals, often require temporary storage solutions for perishable items. Commercial cold rooms provide an ideal way to keep food and beverages fresh during these occasions. You can use these cold rooms to store everything from pre-prepared meals to chilled drinks, ensuring that your guests enjoy high-quality refreshments.

Temporary cold storage is especially useful for catering businesses. It allows you to manage inventory efficiently and reduce waste. For example, you can prepare dishes in advance and store them safely until they are ready to be served. This not only saves time but also ensures that the food remains fresh and safe for consumption.

Tip: When renting a cold room for an event, choose a model with adjustable temperature settings. This flexibility helps you store a variety of items, from frozen desserts to chilled beverages, in one space.

Cold rooms designed for hospitality applications often come with features like easy mobility and quick installation. These benefits make them a practical choice for event organizers who need reliable refrigeration on short notice.

Other Industries

Commercial cold rooms also play a crucial role in industries beyond food and hospitality. For example, the pharmaceutical sector relies on these storage solutions to preserve temperature-sensitive products like vaccines, medicines, and lab samples. Maintaining the correct environment ensures the safety and efficacy of these items.

In research facilities, cold rooms are used to store chemicals and biological samples. These spaces provide precise temperature control, which is essential for maintaining the integrity of sensitive materials. You can also find cold rooms in industries like cosmetics and electronics, where certain products require controlled storage conditions to prevent damage.

Note: Cold rooms used for chemical storage must meet specific safety standards. Always ensure that the materials stored are compatible with the room's design and insulation.

Whether you work in pharmaceuticals, research, or another specialized field, commercial cold rooms offer a reliable solution for preserving perishable or sensitive items. Their versatility makes them an essential tool across various applications.

Benefits of Commercial Cold Rooms

Enhanced Product Shelf Life

A commercial cold room helps you extend the shelf life of perishable goods by creating a controlled environment. Refrigeration slows bacterial growth and decay processes, keeping your products fresher for longer. For instance:

Reduced microbial activity prevents spoilage.

Lower respiration rates in fruits and vegetables maintain their freshness.

Proper humidity levels minimize mold growth and dehydration.

Cold rooms also ensure consistent airflow, preventing hot spots that could lead to uneven spoilage. Whether you store fresh produce, dairy, or meat, maintaining the right temperature and humidity levels is essential for preserving quality. This not only reduces waste but also ensures your customers receive high-quality products.

Energy Efficiency and Cost Savings

Energy-efficient refrigeration systems can significantly lower your operational costs. These systems reduce electricity consumption, which translates into smaller utility bills over time. Key features that contribute to energy savings include:

Superior insulation that minimizes energy loss.

Modern compressors that adjust power usage based on demand.

LED lighting, which consumes less energy than traditional bulbs.

By investing in energy-efficient cold rooms, you can save money while reducing your environmental impact. Facilities requiring constant temperature maintenance, such as food storage units, benefit the most from these long-term savings.

Compliance with Safety and Quality Standards

Commercial cold rooms play a vital role in helping you meet food safety standards. Their hygienic design reduces contamination risks, ensuring your products remain safe for consumption. Features like easy-to-clean surfaces and antimicrobial coatings make sanitation simple. Consistent temperature and humidity levels further inhibit bacterial growth, enhancing food safety.

Cold rooms also help you comply with strict industry regulations. For example, they are essential for storing temperature-sensitive goods like dairy and meat. By maintaining a controlled environment, you protect your customers and enhance your business's credibility. Meeting these standards not only ensures compliance but also builds trust with your clients.

Scalability and Customization Options

Commercial cold rooms offer unmatched scalability and customization, making them a versatile solution for businesses of all sizes. Whether you run a small café or a large food processing plant, you can tailor these cold rooms to meet your specific needs.

Scalability: Growing with Your Business

One of the key advantages of commercial cold rooms is their ability to grow alongside your business. Modular cold rooms, for example, allow you to expand storage capacity by simply adding more panels. This feature ensures that your investment remains relevant as your operations scale up.

Tip: Start with a smaller cold room if you're unsure about future storage needs. You can always expand later without replacing the entire system.

Scalability also applies to refrigeration systems. Advanced models let you upgrade compressors or cooling units to handle increased storage demands. This flexibility ensures that your cold room remains efficient and cost-effective, even as your business evolves.

Customization: Tailored to Your Needs

Customization options let you design a cold room that aligns perfectly with your operational requirements. You can choose the size, temperature range, and even additional features like humidity control or automated monitoring systems.

For instance:

Food Industry: Add shelving systems for better organization.

Pharmaceuticals: Install precise temperature controls for sensitive products.

Floral Storage: Opt for high humidity settings to preserve freshness.

Note: Customization ensures that your cold room operates efficiently, reducing energy waste and improving product quality.

By investing in scalable and customizable cold rooms, you can future-proof your business while meeting specific storage needs. This adaptability makes them a smart choice for any industry.

Energy Efficiency and Maintenance of Cold Rooms

Choosing Energy-Efficient Models

Selecting an energy-efficient cold room model can significantly reduce your operational costs and environmental impact. To make the right choice, consider the following features:

Size and Capacity Requirements: Choose a model that matches your storage needs. Oversized systems waste energy, while undersized ones struggle to maintain temperature control.

Refrigerant Type: Opt for environmentally friendly refrigerants like ammonia or carbon dioxide. These options have minimal impact on the environment.

Energy Efficiency Rating: Look for models with high Energy Efficiency Ratio (EER) or Seasonal Energy Efficiency Ratio (SEER) ratings. Higher ratings mean better energy savings.

Compressor Technology: Advanced compressors, such as variable speed models, adjust output based on demand, reducing energy consumption.

Defrosting Method: Efficient defrosting methods, like hot gas defrost, conserve energy and maintain consistent temperatures.

Insulation Integration: Ensure the system works with high-quality insulation to minimize heat ingress.

Control Systems: Advanced systems monitor and regulate temperature and energy use, optimizing performance.

By focusing on these features, you can invest in a cold room that balances efficiency and functionality.

Regular Maintenance Practices

Regular maintenance ensures your cold room operates efficiently and lasts longer. Follow these best practices:

Inspect and clean components regularly to prevent buildup and wear.

Address any malfunctions immediately to avoid further damage.

Use monitoring systems to maintain optimal temperature and humidity levels.

Organize storage to allow proper airflow and avoid overloading.

Replace parts with high-quality components to enhance durability.

Calibrate temperature sensors for accurate readings.

Train staff to recognize issues and follow proper procedures.

These steps help you avoid costly repairs and ensure consistent refrigeration performance.

Monitoring Temperature and Humidity Levels

Maintaining precise temperature and humidity levels is crucial for product safety and energy efficiency. Use advanced monitoring systems to track these conditions in real time. These systems alert you to fluctuations, allowing you to address issues promptly. Proper monitoring also prevents spoilage and ensures compliance with industry standards.

Tip: Regularly check and recalibrate sensors to ensure accurate readings. This practice helps maintain consistent conditions and reduces energy waste.

Upgrading Insulation and Seals

Proper insulation and seals are critical for maintaining the efficiency of your commercial cold room. Upgrading these components can significantly reduce energy loss and improve temperature consistency. Poor insulation allows heat to enter, forcing the refrigeration system to work harder. This increases energy consumption and operational costs.

Start by evaluating the current insulation material. High-quality materials like polyurethane foam or polystyrene panels offer excellent thermal resistance. If your cold room uses outdated or damaged insulation, replacing it with modern options can enhance performance. Thicker insulation layers also help maintain stable temperatures, especially in extreme environments.

Inspect the door seals regularly. Worn or cracked seals allow cold air to escape, leading to temperature fluctuations. Replace damaged seals immediately to prevent energy waste. Magnetic gaskets are a popular choice because they provide a tight seal and are easy to install.

Tip: Use a simple test to check your door seals. Close the door on a piece of paper. If you can pull the paper out easily, the seal needs replacement.

Consider adding thermal curtains or strip doors inside the cold room. These barriers minimize air exchange when the door opens, keeping the interior temperature stable. Upgrading insulation and seals not only improves energy efficiency but also extends the lifespan of your refrigeration system.

Training Staff for Proper Usage

Your staff plays a vital role in maintaining the efficiency and longevity of your cold room. Proper training ensures they use the equipment correctly and avoid practices that could cause damage or inefficiency.

Begin by educating your team on the importance of temperature control. Teach them how to monitor and record temperature readings. This helps identify issues early and prevents spoilage. Show them how to use monitoring systems and alarms effectively.

Organizing inventory is another key area. Train your staff to store items in a way that allows proper airflow. Overloading the cold room blocks vents and disrupts temperature distribution. Encourage them to follow a first-in, first-out (FIFO) system to reduce waste.

Note: Remind your team to close the door promptly after use. Leaving it open for extended periods causes temperature fluctuations and increases energy consumption.

Regular maintenance tasks should also be part of the training. Teach your staff how to clean the cold room, inspect seals, and report any issues. A well-trained team ensures your cold room operates efficiently and keeps your products safe.

Commercial cold rooms are essential for preserving the quality and safety of perishable goods. They provide consistent low temperatures and humidity, which inhibit bacterial growth and extend product shelf life. These cold rooms also help businesses meet industry standards by maintaining hygiene and preventing contamination. Their importance in various industries, such as food, pharmaceuticals, and florals, cannot be overstated. Investing in energy-efficient and well-maintained cold rooms reduces costs, minimizes waste, and ensures long-term success. By choosing the right cold room, you can protect your products and enhance your business operations.

See Also

Exploring How Cold Rooms Operate and Their Benefits

Comparing Container Cold Rooms and Conventional Cold Storage

Key Differences Between Cold Rooms and Freezer Units

Choosing the Ideal Walk-in Cold Room for Your Needs

Understanding the Differences Between Cold Rooms and Cool Rooms