Fluidized Quick Freezer vs Spiral and Tunnel Freezers Explained

When you pick a freezer for your food line, you need to think about the shape, size, and how delicate the food is. The Fluidized Quick Freezer blows cold air very fast to freeze small or fragile foods quickly. This helps keep the food’s texture and quality good and saves energy. If you want steady results and to spend less money, choosing the right freezer for your needs is very important.

Fluidized Quick Freezer

How It Works

You use a fluidized quick freezer when you want to freeze small or delicate foods. This freezer uses a rapid freezing method. Cold air blows upward through a perforated belt. The air lifts and separates each piece of food. You see the food float and tumble gently. This process helps you freeze each item quickly and evenly. You get individual quick freezing for every piece. The fluidized quick freezer works best for foods that need gentle handling. You avoid clumping and sticking. You keep the shape and texture of your products.

iqf Benefits

You get many benefits from using iqf technology in a fluidized quick freezer. You freeze each piece separately. You keep the original taste, color, and nutrition. You can pack and store iqf foods easily. You reduce waste because you only use what you need. Individual quick freezing helps you save energy. You get better product quality. You can process many types of foods with iqf technology. You see strawberries, blueberries, diced meat, and fruit slices stay fresh and separate. You improve your production speed and efficiency. You meet high standards for individually quick frozen foods.

Limitations

You may face some limits with fluidized quick freezers. You cannot use them for large or heavy items. The freezer works best for small-volume materials. You need to keep the pieces uniform in size. You may need extra sorting before freezing. You may spend more on maintenance for the air system. You may not reach high production volumes like other freezer types. You need to check if your product fits the individual quick freezing process.

Best Uses

You should choose a fluidized quick freezer for foods that need individual quick freezing. You get the best results with iqf products. You can freeze diced meat, meat strips, berries, and fruit slices. You see the freezer work well for small, delicate items. You keep the quality and appearance of your foods. You can look at the table below for common examples.

Food Product Type | Examples |

|---|---|

Small-volume materials | Diced meat, meat strips, strawberries, blueberries, mulberries, raspberries, various fruit slices |

You use fluidized bed freezers when you want high-quality iqf foods. You get fast, gentle, and uniform freezing with iqf technology.

Spiral Freezer

How It Works

Spiral freezers are used in many food factories. These machines have a spiral belt inside a cold chamber. The belt moves food up in a spiral path. Cold air blows around each layer of food. This freezes food fast and evenly. The spiral shape saves space on the floor. You can freeze a lot of food in a small area. You can change the speed and temperature for different foods. This system is good for nonstop work.

Benefits

Spiral freezers have many good points. The small design lets you freeze lots of food without a big room. You can keep your line running all the time. Cold air touches every part of the food, so quality stays high. You can change the belt speed for different freezing jobs. Spiral freezers help save energy and lower labor costs. You can freeze baked goods, pastries, and frozen desserts.

Tip: Spiral freezers are best when you want to freeze food fast and keep its texture and taste.

Limitations

Spiral freezers have some problems. They cost a lot at first, which is hard for small and medium businesses. It can be tough to connect spiral freezers to old food lines. Local makers sometimes cannot match imported units with bigger capacity. See the table below for common problems:

Challenge Type | Description |

|---|---|

Small and medium poultry and bakery businesses pay a lot upfront. | |

Integration Issues | Hard to connect with old processing lines. |

Competition from Imports | Local makers compete with imported units that freeze more food. |

Applications

Spiral freezers are used in many food places. They work well in bakeries and food service kitchens. You can freeze baked goods, pastries, frozen desserts, and bread. Food keeps its texture and taste fresh. The table below shows where spiral freezers work best:

Food Product Type | Production Environment | Suitability for Spiral Freezers |

|---|---|---|

Baked Goods | Bakery Settings | Good for quick freezing to keep texture and taste |

Pastries | Bakery Settings | Keeps quality during storage and display |

Frozen Desserts | Food Service | Works well for freezing and storing lots of food |

Bread | Bakery Settings | Keeps bread fresh and stops freezer burn |

You pick spiral freezers when you need to freeze lots of food all the time. These machines help you keep up with busy work and get steady results.

Tunnel Freezer

How It Works

A tunnel freezer is used to freeze lots of food fast. Food moves through a long chamber on a conveyor belt. Cold air blows hard over the food as it travels. This air freezes the food quickly and keeps it fresh. The iqf freezing tunnel is best for big batches and larger pieces. You can change the belt speed and the temperature inside. This lets you control how quickly food freezes. The tunnel design helps your line run without stopping. You save time and keep things moving smoothly.

Benefits

Tunnel freezers are great for making lots of food. They freeze food quickly and keep it tasting good. The iqf freezing tunnel keeps moisture and flavor inside. You get more work done because the tunnel runs all the time. You need fewer workers since the tunnel works by itself. The tunnel keeps food safe by controlling the temperature and stopping germs. You get the same results every time. The iqf freezing tunnel saves energy by freezing food fast.

Note: Tunnel freezers let you freeze more food in less time, so your work is easier.

Here is a table that shows why tunnel freezers are good for big food jobs:

Benefit | Description |

|---|---|

Fast freezing keeps moisture, nutrients, and flavor, so food stays good. | |

Boosts Productivity | The tunnel runs all the time, so you make lots of food. |

Reduces Labor Costs | Machines do most of the work, so you need fewer people. |

Improves Food Safety | Cold temperatures stop germs from growing. |

Supports Consistency | Every batch freezes the same way, so quality stays high. |

Limitations

Tunnel freezers have some problems. They need a lot of space in your factory. You must have a big area for the iqf freezing tunnel. The tunnel uses lots of energy, so costs go up. You may need special training to use and fix the tunnel. The tunnel is best for big batches, not small or gentle foods. You cannot freeze foods that need soft handling in the tunnel. The iqf freezing tunnel does not work for every kind of food.

Applications

You pick a tunnel freezer for big jobs that never stop. The iqf freezing tunnel is good for meat patties, seafood, poultry, and ready meals. You can freeze vegetables, potato foods, and bakery items in the tunnel. The tunnel helps you keep up with lots of orders. You use the tunnel when you want food frozen fast and still good. The iqf freezing tunnel is great for busy factories and food plants.

Meat patties

Seafood fillets

Poultry pieces

Prepared meals

Potato products

Vegetables

Bakery items

The tunnel freezer gives you steady results for big batches. You get fast, even freezing with the iqf freezing tunnel. You save energy and make more food with tunnel freezers.

Comparison

Speed

When you look at speed, each freezer type works differently. Fluidized quick freezers use a strong blast of cold air. This method freezes small items like berries or diced meat very fast. You get the best results for iqf foods because each piece freezes quickly and separately. Spiral freezers also freeze food fast, but they work best for medium-sized items. The spiral belt moves food through the cold chamber, so you keep a steady pace. Tunnel freezers handle large batches. They use high-velocity air to freeze big amounts of food at once. You can freeze meat patties, seafood, or vegetables in bulk. The freezing process in tunnel freezers is fast for big jobs, but not as quick for small, delicate foods.

Quality

You want to keep the best quality in your frozen foods. The freezing process in each freezer affects texture, moisture, and appearance. Fluidized quick freezers give you enhanced quality for iqf products. You keep the shape, color, and taste of each piece. Spiral freezers also protect quality. They freeze food evenly, so baked goods and desserts stay fresh. Tunnel freezers work well for large items, but they may not be gentle enough for soft or fragile foods. Here is what happens during freezing:

The freezing process slows down changes in color and taste.

Blanching vegetables before freezing helps keep bright color and good texture.

Flash-freezing, like in iqf systems, stops clumping and keeps food looking good.

You see the best quality in iqf foods when you use fluidized quick freezers. Spiral freezers also help you keep quality high for baked goods. Tunnel freezers work best for big, sturdy items.

Efficiency

Efficiency matters when you run a food business. Fluidized quick freezers give you high efficiency for small, uniform foods. You freeze each piece fast and use less energy. Spiral freezers help you save space and energy. You can run your line all day and freeze many types of food. Tunnel freezers give you the highest efficiency for large batches. You move lots of food through the tunnel without stopping. Each freezer type helps you reach your efficiency goals in different ways:

Fluidized quick freezers: Best efficiency for iqf products and small items.

Spiral freezers: Good efficiency for continuous lines and mixed products.

Tunnel freezers: Top efficiency for bulk freezing and big jobs.

You need to match your freezer to your product and production needs to get the best efficiency.

Space

You must think about space in your factory. Fluidized quick freezers take up less space than tunnel freezers. You can fit them into smaller rooms. Spiral freezers save floor space because the belt moves food upward in a spiral. You freeze more food in a smaller area. Tunnel freezers need the most space. The long tunnel takes up a big part of your plant. If you have limited space, spiral freezers give you the best option. Fluidized quick freezers also fit well in small spaces for iqf foods.

Cost

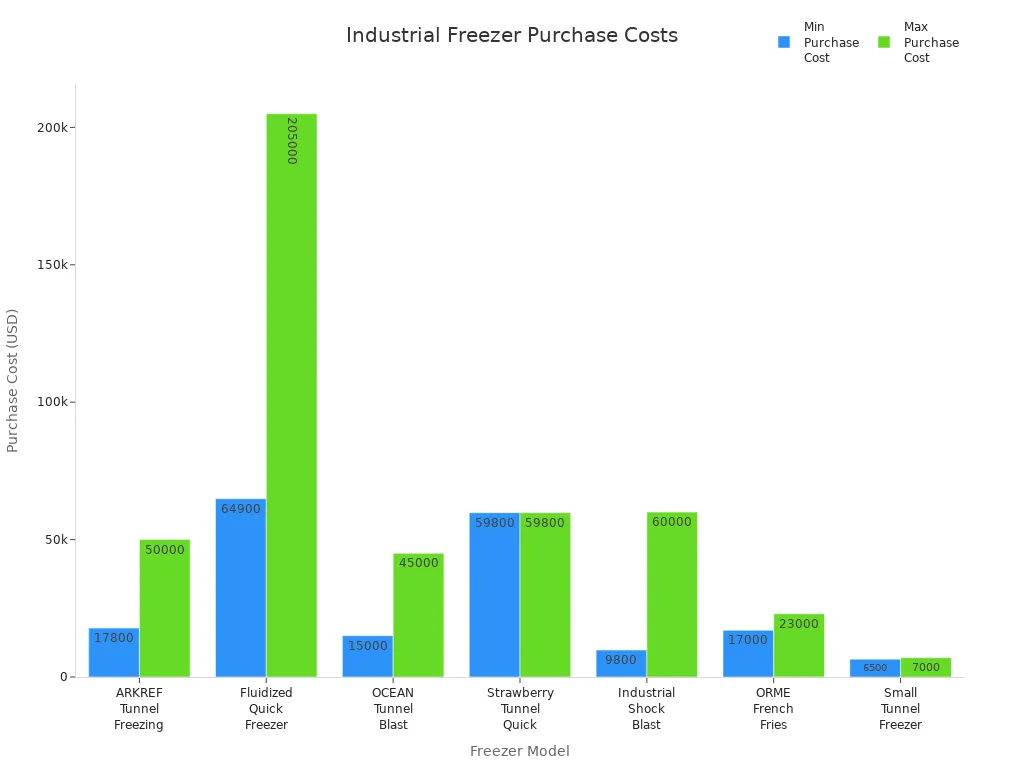

Cost is a big factor when you choose a freezer. Fluidized quick freezers cost more to buy than some tunnel freezers, but they give you better iqf results. Spiral freezers have a high initial cost, but you save money over time with lower labor and energy costs. Tunnel freezers have a wide price range. You can find small tunnel freezers for less money, but large ones cost more. Here is a table with sample prices:

Product Name | Price Range |

|---|---|

ARKREF IQF Tunnel Fast Freezing Machine | $17,800-50,000 |

Fluidized Quick Freezer for Fruit/Vegetable | $64,900-205,000 |

OCEAN Vegetable IQF Tunnel Blast Freezer | $15,000-45,000 |

Strawberry Tunnel Quick Freezer | $59,800 |

Industrial IQF Shock Blast Freezer | $9,800-60,000 |

ORME French Fries Conveyor Belt Freezer | $17,000-23,000 |

Small IQF Tunnel Freezer with Pump | $6,500-7,000 |

You need to balance cost with efficiency and quality. Sometimes, a higher cost gives you better results and lower running costs.

Suitability

You must pick the freezer that fits your product and business. Fluidized quick freezers work best for iqf foods like berries, diced meat, and fruit slices. You get top quality and efficiency for small, delicate items. Spiral freezers suit bakeries and food service kitchens. You freeze bread, pastries, and desserts with high quality and steady results. Tunnel freezers fit large factories that freeze meat, seafood, vegetables, and ready meals in bulk. You get the best efficiency for big jobs, but not for soft or fragile foods.

Tip: Always match your freezer to your product type, batch size, and space. This helps you get the best efficiency, quality, and cost savings.

Choosing the Right Freezer

By Product Type

You need to match your freezer to the food you want to freeze. Different foods need different freezing methods for the best results. If you work with small, delicate items like berries, diced meat, or fruit slices, you should choose an iqf freezer. This type of freezer uses fast cold air to freeze each piece separately. You keep the shape and texture of your food. You also improve food preservation and extend shelf life.

For baked goods, bread, or pastries, spiral freezers work well. The spiral belt moves food gently and keeps it from sticking. You get even freezing and good shelf life for your products. Tunnel freezers suit large items like meat patties, seafood, or ready meals. These freezers handle big batches and help food manufacturers keep up with demand. You can freeze vegetables and potato products in tunnel freezers, too.

Tip: Always check if your product needs gentle handling or if it can handle strong air flow. This helps you pick the right freezer for food preservation and quality.

By Volume

You must also think about how much food you need to freeze each day. Small-scale operations, like test kitchens or specialty shops, do not need large machines. You can use a laboratory freezer or a small iqf unit. These freezers handle up to 10 liters and reach very low temperatures for maximum preservation.

Medium-scale businesses, such as local bakeries or small food manufacturers, need more capacity. Plate freezers or blast freezers can freeze up to 400 liters per batch. These freezers help you keep up with orders and maintain shelf life for your frozen foods.

Large-scale factories need the biggest freezers. Tunnel freezers and large plate freezers can freeze hundreds of liters at once. These machines help you process bulk orders and keep your production line moving. You get consistent results and long shelf life for all your products.

Here is a table to help you choose based on your production volume:

Freezer Type | Capacity | Temperature Range |

|---|---|---|

Laboratory freezer (Lab-Scale) | Down to -80°C | |

Plate freezer (Large-Scale) | Up to 400L+/Batch | Down to -80°C |

Blast freezer for pharmaceuticals | Up to 300L | -80°C to +40°C |

Cryogenic freezer | < 250mL/Bag | Down to -170°C |

Note: If you want to freeze large amounts of food, pick a freezer with high capacity. This helps you save time and keep food preservation at its best.

By Budget

Your budget plays a big role in your choice. If you have a small budget, start with a basic iqf or tunnel freezer. These freezers cost less and still give you good results for shelf life and food preservation. You can freeze small batches of frozen foods and keep quality high.

If you have more money to spend, invest in a spiral freezer or a large tunnel freezer. These machines cost more at first, but you save money over time. You use less energy and need fewer workers. You also get better shelf life for your products. Food manufacturers with big budgets often choose these freezers for their efficiency and quality.

💡 Remember: Spending more on the right freezer can help you save money in the long run. You get better food preservation, longer shelf life, and higher quality for your frozen foods.

When you choose a freezer, always think about your product type, how much you need to freeze, and your budget. This helps you pick the best machine for your needs and keeps your business running smoothly.

Fluidized quick freezers are best for small, delicate foods. Spiral freezers are good for bakeries. Tunnel freezers work well for freezing lots of food at once. If you want berries or diced meat to last longer, pick fluidized quick freezers. Spiral freezers help bread and pastries stay fresh longer. Tunnel freezers freeze big batches fast for busy factories.

Before you buy a freezer, look at the technical details, rules, and support after buying. New things like IoT sensors and energy-saving systems help freezers use less power and work better.

Factor | Description |

|---|---|

Technical Specs | Temperature range, cooling speed, noise levels |

Cost-Efficiency | Total cost of ownership, energy, maintenance |

After-Sales Support | Reliable service network, technical support |

Advancement Type | Description |

|---|---|

IoT Sensors | Real-time temperature monitoring |

Energy Recovery |

See Also

Understanding Tunnel Freezers Compared to Spiral Freezers

Selecting Between Tunnel and Spiral Freezers for Efficiency

Cost and Efficiency Comparison of Spiral and Tunnel Freezers

Revolutionizing Food Storage with IQF Tunnel Freezer Technology

Addressing Freezing Challenges with Tunnel Freezer Innovations