How to pick the best cold room supplier easily

Choosing a cold room supplier for your business means you need someone you can trust. You want a partner with a proven track record, not just any company. Look for clear pricing so you don’t get stuck with hidden costs. Make a list of what you need for food storage before you start searching.

Tip: Always ask about durability, energy efficiency, and ongoing support. These factors save you money and headaches later.

Key Takeaways

Know what your business needs before you pick a cold room supplier. Write down how much storage you need and the temperature you want.

Look at what people say about the supplier. Read reviews and ask how long they have worked. Good suppliers get nice comments from customers.

Pick cold rooms that use less energy. They lower your bills and are better for the earth.

Ask for prices that are easy to understand and get a quote in writing. This helps you see all costs and compare suppliers.

Make sure the supplier gives good help after you buy. Regular checks and fast help keep your cold room working well.

Business Needs

You should know what your business needs before picking a cold room supplier. Make a clear list of your needs. This helps you get a cold room that fits your work. Let’s look at the main things to think about.

Storage Capacity

Think about how much space you need for storage. If your cold room is too small, you could lose products. Here is what can happen if you don’t have enough space:

Most cold rooms only store potatoes, so other foods are not kept well.

Over 37 lakh tonnes of food gets wasted every year because there is not enough cold storage.

If you plan for the right amount of storage, you can keep your products safe.

Temperature Range

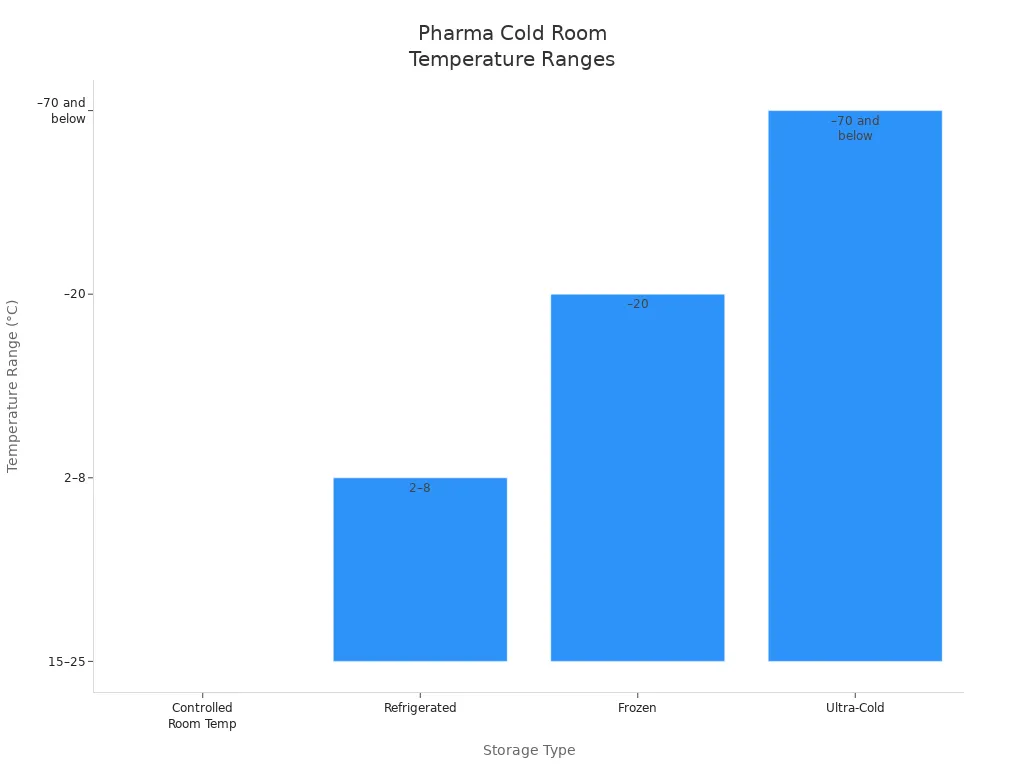

Different products need different temperatures. Medicines, vaccines, and frozen foods all need special care. Here is a table that shows the temperature ranges for pharmaceutical cold rooms:

Temperature Range | Application |

|---|---|

Controlled Room Temp | 15–25 °C / 59–77 °F (medicines and health products) |

Refrigerated | 2–8 °C / 36–46 °F (vaccines, dairy, fresh produce) |

Frozen | around –20 °C / –4 °F (frozen foods, some pharmaceuticals) |

Ultra-Cold | –70 °C / –94 °F and below (certain biologics, lab samples, specialized vaccines) |

If you know what temperatures you need, you can ask your supplier for the right cold chamber.

Space and Insulation

You need enough space in your cold room. There should be room for shelves and for people to move safely. Insulation is also very important. Good insulation keeps the cold air inside and saves energy.

Insulation is like a strong shield against weather changes. It helps you use less heating and cooling. This saves energy and makes your HVAC systems last longer.

Here is why insulation is important:

It keeps the temperature steady inside your cold room.

You can save money on your energy bills.

When you talk to a supplier, tell them what you need for space and insulation. This helps you get the best cold room for your business.

Cold Room Supplier Reputation

When you pick a cold room supplier, you want someone honest. You need to trust that they will do what they say. Let’s see how you can find a supplier you can trust.

Years in Business

Experience is important. If a supplier has worked for many years, they know the business well. Many years mean they have done lots of projects. They have solved many problems. You can ask, “How long have you sold cold rooms?” Suppliers with more years often have better answers for your needs.

Tip: Suppliers who have worked longer usually help customers better. They know how to fix hard problems.

Customer Reviews

You should always read what other buyers say. Reviews show if a supplier keeps their word. Look for comments about quality, delivery, and service. If you see many good reviews, you can feel sure. Be careful if a supplier hides reviews or has only a few. That can be a warning sign.

Here’s a quick checklist for reading reviews:

Are customers happy with the cold room quality?

Do they mention good customer service?

Is delivery on time?

Are there complaints about hidden costs?

Certifications

Certifications show that a supplier follows important rules. You want to see things like ISO 1496-2, HACCP, GDP, or GMP. These mean the supplier cares about safety and quality. Ask to see their certifications before you choose. If a supplier cannot show them, look for another one.

Here’s a table that shows what to look for in a reputable cold room supplier:

Indicator Type | Description |

|---|---|

Technical Specifications & Standards | Units should meet international standards like ISO 1496-2, with specs for temperature range and cooling capacity. |

Industry Compliance Requirements | Compliance with HACCP for food and GDP/GMP for pharmaceuticals is essential. |

Performance Metrics & Benchmarks | Check pull-down time and temperature uniformity for efficiency. |

Cost-Efficiency Factors | Look at total cost of ownership, including energy use and maintenance costs. |

Quality Assurance Considerations | Inspect build quality and ask for material certifications for durability and safety. |

Integration Capabilities | Make sure the cold room works with your existing systems for easy monitoring. |

After-Sales Support Evaluation | Look for strong warranties and fast technical support from the supplier. |

Note: Suppliers who show their certifications and quality rules are usually more trustworthy. If a supplier hides this, you should be careful.

Picking a supplier with a good name helps you avoid trouble later. You get better quality, stronger help, and feel safe about your storage.

Cold Room Quality

If you want a cold room, you should look for good quality. You need one that lasts long, saves energy, and fits your business needs. Let’s see what makes a cold room special.

Durability

Your cold room should last many years. The right materials help a lot. Many good cold rooms use strong panels and thick insulation. Here are some materials you should check for:

Polyisocyanurate (PIR) panels

Polyurethane foam

Polystyrene foam

Mineral wool

Cellular glass

These materials help your cold room work well every day. They also keep your storage safe from heat and cold outside. If you pick a cold room with these materials, you get better quality and fewer fixes.

Tip: Ask your cold room supplier about the panels and insulation they use. Good materials mean your cold room will last longer.

Energy Efficiency

Cold rooms can use a lot of energy. You want one that keeps bills low. New cold rooms use smart technology to save power. For example, variable frequency drive (VFD) compressors can save 30-40% more energy than old ones. This means you spend less money each year.

A good cold room keeps the temperature steady without wasting power. Good insulation and smart controls help stop energy waste. You save money and help the planet too.

Save up to 40% on energy with VFD compressors

Keep storage safe with steady temperatures

Lower your cold storage bills every month

Note: Energy-efficient cold rooms often meet higher quality standards. They also help your business run better.

Customization

Every business needs something different. You might want special doors, thicker insulation, or digital controls. A good cold room should fit your needs. Customization lets you pick what matters most.

Here are some choices you can ask for:

Feature | Details |

|---|---|

Door Type | Swing/Sliding |

Custom Door Size | Yes |

Controller | Digital Temperature Controller |

Defrosting | Automatic Defrosting |

Insulation Thickness | 50mm To 250mm |

When you talk to your cold room supplier, ask about these options. The right choices help you keep your storage safe and improve quality. You get a cold room that works for you.

Callout: Custom features make your cold room safer, easier to use, and better for your storage.

If you choose a cold room with strong materials, smart energy use, and custom features, you get the best quality. Your storage stays safe, your costs go down, and your business works better.

Pricing and Support

When you pick a cold room supplier, you need to know what you pay for. You also want to know what help you get after buying. Let’s see what to check for in pricing and support.

Transparent Quotes

Always ask for a price list that is easy to understand. A good supplier gives you a list with prices for each part. This list should show costs for panels, doors, and controls. You do not want to find extra fees later. If a supplier cannot explain their prices, you should look for another one.

Tip: Ask for a written price list with every cost. This helps you compare suppliers and spot hidden fees.

Warranty

A good warranty helps you feel safe. Most top suppliers give a one-year warranty from when they ship your cold room. This covers problems with materials and how it was made. If something breaks, you can get it fixed or replaced. Here is a quick look at normal warranty terms:

Warranty Type | Duration | Conditions |

|---|---|---|

Purchased Equipment Warranty | Free from defects in materials and workmanship; must perform according to specifications. | |

Subscription Equipment Warranty | Initial Subscription Term | Free from defects in materials and workmanship; must perform according to specifications. |

Warranty Remedies | N/A | Replacement or repair of non-conforming equipment; return of claimed equipment within 30 days. |

Exclusions and Limitations | N/A | Warranties void for misuse, unauthorized modifications, and other specified conditions. |

Read the warranty rules before you buy. This helps you know what is covered and what is not.

Maintenance Services

Getting help after you buy is very important. You want a supplier who gives regular check-ups and quick help if something breaks. Good support keeps your storage safe and stops you from losing products. Some suppliers even have emergency help, so you do not worry about problems.

Pick a supplier with a 24/7 help line.

Ask if they do regular check-ups.

Make sure they can send someone fast if you need help.

Callout: Good support keeps your cold room working well and protects your money.

Choosing a cold room supplier with clear prices, a strong warranty, and good support helps your business work better and keeps your storage safe.

Delivery and Decision

Lead Times

You need your temperature controlled rooms on time. Lead times are very important. Some cold room suppliers deliver fast. Others take more time. Ask each supplier how long it takes to install. Compare their answers to see who is faster. Fast delivery lets you start using your cold storage sooner.

Tip: Make sure the supplier can finish on your schedule before you agree.

Logistics

Logistics help your installation go smoothly. Good logistics mean your temperature controlled rooms arrive when you need them. They also get set up without problems. Here’s what good logistics can do:

Make installation faster with good planning.

Stop delays by following all the rules.

Use tracking and smart tools to find problems early.

If your cold room supplier uses new logistics, you will have fewer problems. Your cold storage will work better.

Final Selection

You are almost ready to choose. Look at all the facts before you decide. Here’s a table to help you compare what matters most:

Factor | Details |

|---|---|

Energy Consumption | Measured per m³/day, important for operational cost assessment. |

Maintenance Costs | Includes filter replacements and coil cleaning expenses. |

Lifespan Expectancy | Quality units typically last 12-15 years, affecting long-term investment. |

Quality Assurance | Look for IP66-rated components and certifications like UL, CE, Eurovent. |

Integration Capabilities | Ensure compatibility with management systems and pre-wired control panels. |

After-Sales Support | Check for a minimum 5-year warranty, 24/7 support, and local service. |

Pick the best suppliers and ask for detailed offers. When you talk about price, try these ideas:

Strategy | Description |

|---|---|

Know what the supplier wants so you can find common ground. | |

Defining Clear Objectives | Set your goals for cost, delivery, and support. |

Collaborative Approach | Work together for a win-win deal. |

Flexibility | Stay open to new ideas and solutions. |

Clear Communication | Talk openly to avoid confusion. |

Proper Documentation | Get everything in writing for future clarity. |

Note: Good talks and clear support help you get the best cold room for your needs.

Picking the right cold room supplier helps your business. It keeps your products safe and fresh. When you trust your supplier, you get more than a cold room. You also get many long-term benefits. Here are some of them:

Benefit | Description |

|---|---|

Quick Installation | The setup is fast and needs little site work. |

Customizable Solutions | You can pick sizes and layouts that fit your needs. |

Energy Efficiency | Good insulation helps control temperature and saves money. |

High-Quality Materials | Strong materials make the cold room last longer and work better. |

You can make a good choice by doing these things:

Visit the factory to check how they work.

Look at how often they deliver on time and how often people reorder.

Ask for samples to test before you buy.

See if they answer fast and offer custom options.

Focus on suppliers who are reliable and clear about prices. Make sure they give good support after you buy. Start checking different suppliers now so you can feel sure about your choice!

FAQ

How do you know if a cold room supplier is trustworthy?

Check what other people say in reviews. Ask if the supplier has certifications. Look for clear warranty rules. Trustworthy suppliers show their certifications. They also give good customer service.

What questions should you ask a cold room supplier before buying?

Ask how long delivery will take. Find out about maintenance and quality standards. Request a written price quote. Ask about help after you buy. These steps help you avoid problems and pick the best supplier.

Can you customize your cold room for special business needs?

Yes, most suppliers let you choose custom options. You can pick door types and insulation thickness. You can also ask for digital controls. Customization helps your cold room fit your business.

Why is energy efficiency important when choosing a cold room supplier?

Energy-efficient cold rooms help you save money. Good insulation and smart controls keep the temperature steady. You spend less on energy. Your products stay safe and fresh.

What kind of support should you expect from a cold room supplier?

You should get regular maintenance and fast emergency help. Good suppliers offer 24/7 support. They also give strong warranties. This keeps your cold chamber working well.

See Also

Choosing The Ideal Walk-in Cold Storage Solution

Leading Cold Room Suppliers For Efficient Logistics

Essential Advice For Effective Cold Room Temperature Management