How to Select the Right Chiller for Your Critical Cooling Needs

When you pick a chiller for important cooling, reliability matters most. If you choose the wrong one, your machines might get too hot or stop working. This can lead to expensive breaks in work. Many people now want chillers that save energy and help the planet. You should choose carefully to keep your equipment safe and help the environment.

Key Takeaways

Pick a reliable chiller to stop equipment from getting too hot and breaking down. Make sure it has strong cooling power and good help from the company.

Think about saving energy when picking a chiller. High COP and EER ratings can help lower your energy bills and help the environment.

Know your thermal load before you pick a chiller. Good measurements help you get the right size for the best cooling.

Regular care is important to make your chiller last longer. Make a plan to check and fix your system so it works well.

Use new technology like smart controls and hybrid systems. These features make your chiller work better and can save a lot of energy.

Chiller Selection Factors

Reliability

You need a chiller that works every time. Reliability means your cooling system keeps going, even when it is busy or the weather is bad. If your chiller stops, your equipment can get too hot and break. This can cause big trouble and cost lots of money. When you think about reliability, look at these things:

Cooling capacity: Make sure the chiller fits your needs. It is measured in tons or kW.

Energy efficiency: High COP and EER save you money.

Durability: Pick a chiller that is strong and lasts long. This helps you avoid repairs and downtime.

Vendor support: Choose a company with good service and help.

Tip: Ask about service and spare parts before you buy. Fast help can stop long waits.

Performance

Chiller performance shows how well your cooling works. You want a unit that fits your needs and keeps things safe. Use these ideas to compare models:

Cooling capacity: Check if the chiller meets your needs. Big spaces need more cooling.

Energy efficiency: Look for high COP and EER. These ratings lower your bills.

Reliability and durability: A good vendor with strong warranties helps you worry less.

Technological innovation: Smart controls and eco-friendly refrigerants help performance.

Installation and maintenance: Easy setup and care save you money.

Cost and financing: Think about the price now and later.

Compliance and certifications: Make sure the chiller follows local rules.

Customer support: Good help and easy parts keep your system working.

SEPR is another key number. If it is above 6, the chiller works well in real life.

New things like multi-scroll compressors and smart fan controls help save energy.

Metric | Description |

|---|---|

COPSHC | More than twice the cooling-only COP, better than natural gas or electric heat |

Energy Reduction | Recovering heat increases chiller efficiency and lowers energy use and emissions |

Efficient chillers stop overheating in data centers and factories. Certified chillers can save up to 25% in pumping energy. If your cooling does not work well, it uses more energy and breaks more often. In 2025, many data centers use new cooling like liquid cooling and free-air cooling. These can cut cooling energy by up to 40%. Better chiller performance means lower costs and less pollution.

Note: Always look at chiller performance curves. These show how the unit works with different loads and temperatures. Knowing these curves helps you pick the best model.

Energy Efficiency

Energy efficiency is very important for most businesses. An efficient chiller uses less power and saves you money. It also helps the environment. You can check efficiency with different ratings:

Evidence Description | Details |

|---|---|

System Efficiency Index (SEI) | SEI shows how close the chiller gets to perfect efficiency in real life. |

Chiller Monitoring | Good monitoring helps you reach top energy efficiency in your building. |

Continuous Recommissioning | Tools like ClimaCheck Monitor give you data to keep improving chiller performance. |

Efficient chillers can save money in many places:

Application | Energy Savings (%) | Description |

|---|---|---|

Data Centers | Up to 30% | Chillers change to match server loads and use energy wisely. |

Skyscrapers & Malls | 15-20% | Smart chillers change cooling based on how many people are inside. |

Manufacturing Plants | N/A | Advanced controls lower maintenance costs and make chillers last longer. |

District Cooling | N/A | Central systems use less energy and work more efficiently. |

You should always check chiller performance curves to see how efficiency changes with different loads. Watching and checking your system helps you use less energy. By picking efficient chillers, you save money and help the planet.

Cooling Requirements

Thermal Load

You must know your heat load before picking a chiller. The heat load shows how much heat your system must remove. This keeps things cool. If you guess wrong, cooling will not work well. You could waste energy or harm your equipment. Here are some key facts about thermal load:

Thermal load estimation helps you set superheat and subcooling levels right.

High heat load means you must manage refrigerant very carefully.

If you get the heat load wrong, your chiller may run badly or break.

Always measure the heat load for your space or process. This helps you pick the right chiller size. When you do this, your cooling system works better and lasts longer.

Tip: Check your heat load often, especially if things change.

System Needs

Every cooling system has its own needs. You must think about more than just heat load. Think about how your system will run each day. The table below shows what you should check before picking a chiller:

Requirement | Description |

|---|---|

Cooling Capacity | Make sure the chiller can handle the highest heat load. |

Refrigerant Options | Pick refrigerants that are safe and follow rules. |

Energy Efficiency | Choose chillers with high COP ratings to save money. |

Maintenance Requirements | Easy service and access help you save money over time. |

Scalability | Your system should grow or change as your needs change. |

Installation Considerations | Check if the chiller fits your space and works with your current setup. |

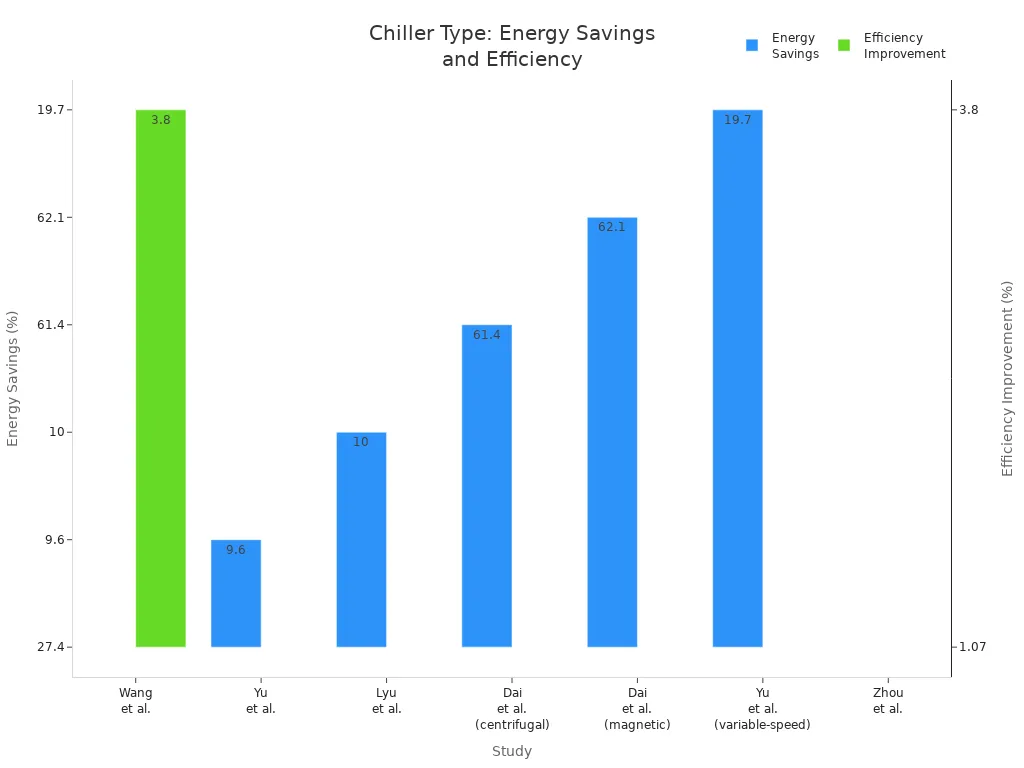

Your needs may depend on the type of process you run. Some studies show changing supply and return temperatures can help chillers work better. Using dual-temperature chilled water systems or magnetic bearing chillers saves lots of energy. The chart below compares energy savings and efficiency from different chiller setups:

Always match your chiller to your needs. This helps you get the best cooling, save energy, and keep your equipment safe.

Chiller Solutions

Water Chiller

A water chiller uses water to cool things down. It works best for big spaces or heavy machines. You often see water chillers in large buildings and factories. Data centers also use them. Water chillers give steady cooling. This helps equipment last longer. You need a cooling tower with a water chiller. This means you need more space. You also need to check it often. Many people pick water chillers for energy savings. They also like the strong cooling power. Water chillers are good when you want exact temperature control. They help you save money over time.

Air Blast Chiller

An air blast chiller uses air to cool. You see these chillers outside on roofs or next to buildings. Air blast chillers are easy to put in place. They need less care than water chillers. These chillers work well in cool weather. They cost less to set up. But they do not cool as much as water chillers. You might pick this chiller for small buildings. It is good if you want a simple system. The table below shows how these chillers are different:

Feature | Air-Cooled Chillers | Water-Cooled Chillers |

|---|---|---|

Cooling Mechanism | Cooled by ambient air | Uses water for cooling |

Condenser Location | Outside (roof or ground level) | Inside, surrounded by pipes |

Maintenance | Lower maintenance, clean condenser coils | Requires cooling towers and regular upkeep |

Energy Efficiency | Generally less efficient | More energy-efficient due to lower temperatures |

Cooling Capacity | Limited cooling capacity | Greater cooling capacity |

Pros | Lower costs, better in freezing temps | Precise control, longer equipment life |

Cons | Reliance on air, limited capacity | Higher water consumption, larger footprint |

Advanced Technologies

Some chillers have new smart features. These chillers use variable-speed drives and oil-free systems. They help you save energy and money. Oil-free centrifugal chillers are very efficient. They also need less care. You see these chillers in big HVAC systems and data centers. They are also used in factories. Smart controls make these chillers even better. Improved heat exchangers help too. These chillers are good for process cooling. Regular checks help you find problems early. Oil tests and vibration checks keep chillers working well. Many companies buy these chillers now. They want to save energy and meet new cooling needs.

Tip: Pick chillers that fit your needs. Smart chillers can save you money and keep your equipment safe.

Maintenance

Regular Service

You must take care of your chiller often. This keeps your cooling system working well. If you follow a plan, you can find problems early. This helps you avoid expensive fixes. Check your chiller often and clean it to keep air moving. Look at the table to see when to do each job:

Interval | Maintenance Task | Purpose & Method | Key Point |

|---|---|---|---|

Daily | Status check | Use the morning checklist | Make it a habit |

Weekly | Clean dust screens | Blow dust out with compressed air | Keep airflow clear |

Monthly | Inspect water quality | Look for algae or clumps; check hoses | Stop contamination |

Every 3–6 months | Change cooling water | Drain old water, flush pipes, add clean water | Do not use tap water |

Annually | Replace water filter | Take out and put in a new filter cartridge | Protect water lines |

Tip: Make a checklist for your chiller care. This helps you remember each step and keeps your chiller working well.

If you service your chiller often, it keeps temperatures steady. This is important for places like data centers and therapy rooms. If you skip maintenance, your chiller may run too much and wear out faster. Good care helps you save energy and improve production.

Longevity

You want your chiller to last a long time. Taking care of it helps you reach this goal. The table shows how long different chillers can last:

Chiller Type | Average Lifespan |

|---|---|

Self-contained units | 5–10 years |

Ducted units | 10–15 years |

Split systems | Up to 20 years |

Wine fridges/coolers | 10–15 years |

To help your chiller last, install it carefully and keep up with care. Clean the condenser, check air filters, and watch for moisture. Plan for expert checks and use your system gently. Humidity and temperature can also change how long your chiller lasts. If you look after your chiller, it will last longer and save you money.

Sustainability

Energy Savings

You can save lots of energy with the right chiller. New systems use smart controls and hybrid designs. Hybrid chillers use both air and water cooling. This helps your system handle different jobs. It also makes your chiller last longer. Smart controls watch your cooling needs. They change how the chiller works to fit your needs. This means you get better cooling and lower bills. If you take care of your chiller often, it works well. You stop wasting energy and avoid sudden problems.

Here is a table that shows good ways to save energy with chillers:

Strategy | Description |

|---|---|

Hybrid Systems | Use air and water cooling together for better results and longer life. |

Smart Controls | Advanced controls help match energy use to what you need. |

Scheduled Maintenance | Check and fix your chiller often so it does not waste energy. |

Absorption chillers use heat that would be wasted or renewable energy. This means you do not need as much fossil fuel. Many cities use these chillers for district cooling. This helps everyone use less energy and lowers the highest demand.

Absorption chillers use waste heat or renewable energy.

You use less energy and make less carbon pollution.

Cities use these chillers for district cooling, so each building uses less energy.

Tip: If you pick a chiller with smart controls and plan regular checks, you can save more energy every year.

Environmental Impact

You help the planet when you pick a chiller with green features. New chillers use refrigerants like R32. R32 does not harm the planet as much as older gases. This means you make less pollution. Scroll compressors and microchannel condensers help chillers use less energy. You spend less money and help keep the air clean.

The table below shows how new chiller technologies help the environment:

Feature | Description |

|---|---|

Refrigerant | R32 lowers pollution and helps the planet. |

Energy Efficiency | Scroll compressors and microchannel condensers save energy. |

Cooling Capacity | Chillers work for many jobs, from 13 kW to 115 kW. |

Extra Features | Electronic valves, EC fans, and smart monitoring make chillers work better. |

Environmental Impact | New chillers follow global rules and make less carbon pollution. |

You can help your business meet green goals and follow new laws. When you pick chillers that help the planet, you save money too. Smart choices now help make the future cleaner.

Choosing the Best Chiller

Checklist

You need a simple checklist when picking the best chiller. This helps you remember every step. Start by looking at the main parts and features. The table below shows what you should check before you choose:

Checklist Item | Description |

|---|---|

Valves Check | Make sure each valve is facing the right way and works well. |

Strainers Check | Clean the mesh and check if you can reach it easily. |

Supports & Anchoring | Look at the spacing and make sure everything lines up. |

Expansion Joints & Insulation | Check that rubber joints and insulation are put in the right way. |

You also need to think about how well the chiller works and if it follows the rules. The next table shows what to look for when you compare chillers:

Criteria | Description |

|---|---|

Cooling Capacity | Shows if the chiller can cool enough for big places. |

Energy Efficiency | High EER or IPLV means you spend less money over time. |

Reliability & Durability | Good vendors use strong parts so your chiller does not break often. |

Ease of Maintenance | Easy-to-fix designs and remote checks make care simple. |

Environmental Compliance | The chiller must follow rules like EPA or EU standards. |

Vendor Support & Service | You need help and spare parts to keep your chiller working. |

Tip: Always ask your chiller company about service plans and spare parts. Good help can stop long waits if something breaks.

Next Steps

After you finish your checklist, you can move forward with confidence. Here are the steps you should follow to make sure your chiller works well for years:

Review Compliance and Documentation

Make sure your chiller follows all local and world rules. Check for certifications and ask your vendor for papers.Plan for Installation

Work with experts to set up your chiller. Check all valves, strainers, and supports before you start. Make sure expansion joints and insulation are ready.Monitor Performance Daily

Write down key numbers like pressure, temperature, and refrigerant levels every day. Watch for sudden changes. This helps you find problems early.Optimize Operation

Use variable frequency drives to change motor speed when you need more or less cooling. Lower the speed when you do not need much cooling. Raise it when you need more.Schedule Regular Maintenance

Make a plan for care. Clean strainers, check water flow, and look at insulation often. Regular checks help your chiller last longer.Analyze Data Trends

Look at your daily logs to see patterns. If you see a big jump in temperature, act fast. This can stop bigger problems.Stay in Touch with Your Vendor

Keep talking to your chiller vendor for help and spare parts. Good support helps you fix problems fast and keeps your chiller running.

Note: Keeping daily logs is very important. Track things like ΔT, cooling capacity, and condenser approach. This helps your chiller work its best.

By following these steps, you make sure your chiller fits your needs and works well for a long time. Picking the best chiller is not just about buying one. It is about planning, checking, and working with your vendor to get the best results.

You should pick a chiller that is reliable and works well. Make sure it does not waste energy. Use a checklist to look at different choices. Ask people who know a lot for help. Taking care of your chiller helps it last longer. It also saves you money. If you change filters often, you can use up to 15% less energy. Cleaning the coils can make your chiller work 30% better. These things help your cooling system stay strong and cost less.

Changing filters often helps your chiller use less energy and last longer.

Cleaning the coils makes your chiller work better and keeps bills low.

FAQ

What size chiller do you need?

You need to match the chiller size to your heat load. Measure the total heat your equipment makes. Choose a chiller with a little extra capacity for safety. Ask an expert if you feel unsure.

How often should you service your chiller?

You should check your chiller every day. Clean filters and screens each week. Change water and inspect parts every few months. Plan a full service once a year. Regular care keeps your chiller running well.

Can you use one chiller for many machines?

Yes, you can use one chiller for several machines. Make sure the chiller has enough capacity for all machines running at the same time. Use flow controls to balance cooling.

What is the best way to save energy with a chiller?

Use smart controls and schedule regular maintenance. Clean coils and change filters often. Pick a chiller with high energy ratings. These steps help you lower your energy bills.

See Also

Maximizing Efficiency in Your Walk-In Chiller System

Improving Performance of ARKREF CO₂ Chillers and Compressors

A Guide to Choosing Industrial Water Chiller Units

Selecting the Perfect Walk-In Cooler: An In-Depth Guide

Boosting Industrial Cooling Efficiency with ARKREF CO₂ Systems