Ever Wonder How Transcritical CO2 Systems Work

You see transcritical CO2 systems in lots of new stores. These systems use carbon dioxide to cool food. They work with higher pressure and temperature than old systems. You notice that food cools faster. They do less damage to the environment. Many technicians like these systems because they use new technology. People who care about the planet like their low impact.

Tip: If you learn how transcritical CO2 works, you can make smarter choices for saving energy and helping the planet.

Key Takeaways

Transcritical CO2 systems use carbon dioxide to cool food. They are better for the environment than older systems. These systems work above the critical point of CO2. This helps them cool well even when it is hot. Important parts like the compressor, gas cooler, and evaporator work together. They keep food fresh and help save energy. Regular maintenance is needed for these systems. Proper training is also important for safe use. Using CO2 refrigeration lowers greenhouse gas emissions. It helps make the planet healthier.

What Is Transcritical CO2 Refrigeration

System Definition

You can find co2 refrigeration systems in many new supermarkets. These systems use co2 as the main cooling gas. Transcritical co2 means the system works above a certain point. This point is called the critical point for co2. At this point, co2 changes how it acts. When the system runs above this point, it is called transcritical refrigeration. This system is different from old systems that use other gases. Co2 refrigeration uses high pressure to move heat out. The system pushes co2 through pipes, compressors, and coolers. This gives cold air for food and drinks.

Note: The critical point for co2 is about 31°C (88°F) and 73.8 bar (1070 psi). Above this point, co2 does not turn into a liquid. The system must handle both gas and liquid in new ways.

Purpose and Use Cases

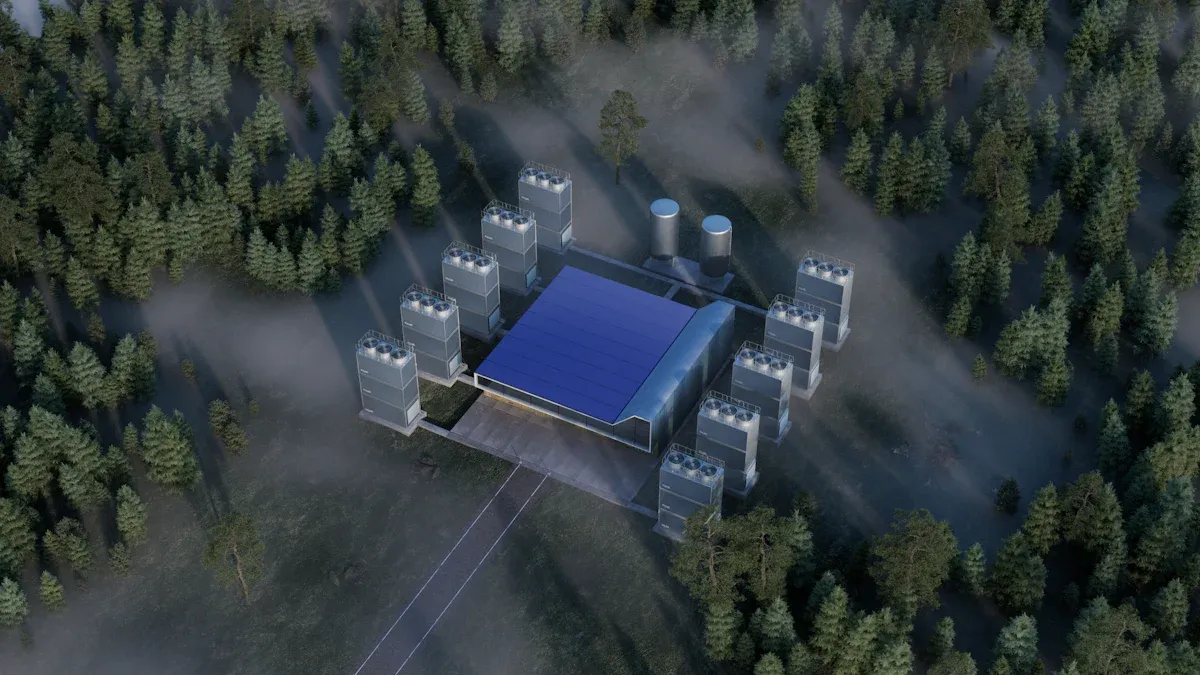

Co2 refrigeration is used where food needs to stay fresh. Supermarkets, grocery stores, and big food warehouses use these systems. Some places use co2 refrigeration to help the environment. Transcritical co2 systems lower greenhouse gas emissions. Using co2 refrigeration helps the planet more than old systems. Many businesses choose co2 refrigeration because it follows new eco-friendly rules. Co2 refrigeration works well in hot and cold places. The system can change to fit different temperatures and still keep food safe.

Supermarkets use co2 refrigeration for display cases and storage rooms.

Food processing plants use co2 refrigeration to keep products fresh.

Ice rinks and cold storage facilities use co2 refrigeration for large spaces.

Co2 refrigeration is becoming more popular. More stores and companies want to use transcritical refrigeration. It saves energy and is better for the environment.

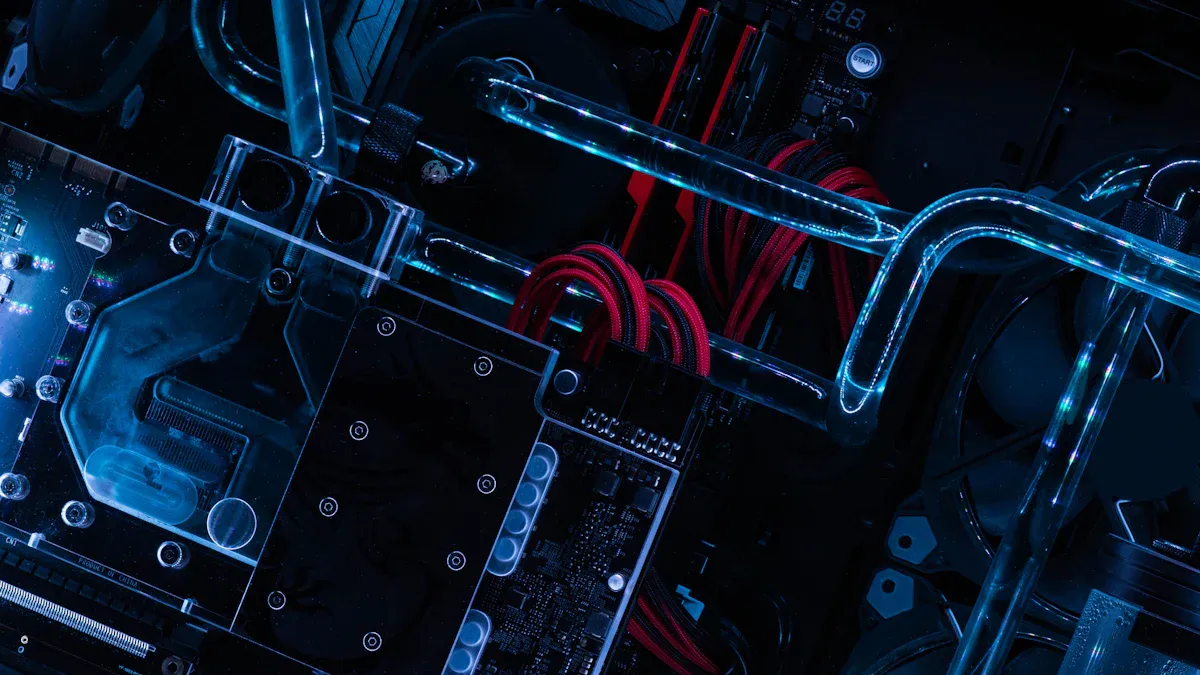

Main Components of CO2 Refrigeration

Compressor and Variable Speed

The compressor is the main part of co2 refrigeration. It pushes co2 through the pipes. Modern systems use variable speed compressors. These compressors can go faster or slower. They change speed to match cooling needs. This saves energy and keeps the temperature steady. The compressor moves co2 from low pressure to high pressure. Smart compressors help co2 refrigeration work better.

Gas Cooler vs. Condenser

You might wonder about gas coolers and condensers. Old systems use condensers to turn gas into liquid. Co2 refrigeration uses a gas cooler instead. The gas cooler lowers co2 temperature but does not make it a liquid. This is because co2 stays above its critical point. The gas cooler is outside the building. It helps co2 release heat into the air.

Tip: Gas coolers are important in hot places. They keep co2 refrigeration safe and working well.

Expansion Valve

The expansion valve comes after the gas cooler. It controls how much co2 goes into the evaporator. The valve drops co2 pressure quickly. This helps make cold air in the system. The valve makes sure co2 flows at the right speed. Co2 refrigeration needs strong valves because of high pressure.

Evaporator

The evaporator is inside the cooling area. It lets co2 take heat from food and drinks. When co2 goes through the evaporator, it picks up heat. This cools the space. You find evaporators in display cases, storage rooms, and freezers. Special evaporators handle high pressure and keep food fresh.

Adaptive Defrost and Heat Recovery

Adaptive defrost stops ice from building up. The system checks for ice and melts it only when needed. This saves energy and keeps the system working well. Heat recovery is also used in co2 refrigeration. The system takes heat from co2 and uses it to warm water or air. This helps the environment and saves money.

Component | What It Does in CO2 Refrigeration |

|---|---|

Compressor | Moves co2 and raises pressure |

Gas Cooler | Lowers co2 temperature |

Expansion Valve | Drops co2 pressure and controls flow |

Evaporator | Absorbs heat and cools the space |

Defrost/Recovery | Removes ice and recycles heat |

Transcritical Refrigeration Cycle

Step-by-Step Operation

You can follow the path of co2 through a co2 refrigeration system to see how it cools food and spaces. The cycle starts at the compressor. The compressor takes low-pressure co2 gas from the evaporator and squeezes it into high-pressure gas. This high-pressure co2 then moves to the gas cooler. The gas cooler sits outside and lets the co2 release heat into the air. The co2 does not turn into a liquid here because the pressure and temperature stay above the critical point.

After the gas cooler, the co2 flows to the expansion valve. The valve drops the pressure quickly. This sudden drop makes the co2 very cold. The cold co2 then enters the evaporator. Inside the evaporator, the co2 absorbs heat from the food or the air in the room. The co2 warms up and turns back into a gas. The cycle repeats as the gas returns to the compressor.

Note: Each part of the cycle helps move heat out of the space you want to keep cool. This keeps food fresh and safe.

Here is a simple list of the steps in a co2 refrigeration cycle:

Compressor squeezes co2 gas to high pressure.

Gas cooler removes heat from co2.

Expansion valve drops co2 pressure and cools it.

Evaporator lets co2 absorb heat from the space.

Co2 returns to the compressor to start again.

CO2 Behavior at Critical Point

You see something special happen to co2 at the critical point. The critical point for co2 is about 31°C (88°F) and 73.8 bar (1070 psi). Above this point, co2 does not act like a normal gas or a normal liquid. It becomes a supercritical fluid. In this state, co2 can hold and move more heat than in regular refrigeration systems.

When you use co2 refrigeration above the critical point, you get transcritical co2 operation. The co2 does not condense into a liquid in the gas cooler. Instead, it stays as a supercritical fluid. This helps the system work in hot weather and in places where old refrigeration systems struggle.

Tip: Supercritical co2 can carry more heat, so co2 refrigeration works well even when outside temperatures are high.

Component Interaction

Each part of a co2 refrigeration system works together to keep things cool. The compressor, gas cooler, expansion valve, and evaporator all play a role. The compressor pushes co2 through the system. The gas cooler removes heat from the co2. The expansion valve controls how much co2 enters the evaporator and how cold it gets. The evaporator absorbs heat from the space and sends the warmed co2 back to the compressor.

You can see how these parts interact in the table below:

Component | What It Does | How It Helps the Cycle |

|---|---|---|

Compressor | Raises co2 pressure | Starts the cycle, moves co2 |

Gas Cooler | Removes heat from co2 | Prepares co2 for cooling |

Expansion Valve | Drops co2 pressure | Makes co2 cold for the evaporator |

Evaporator | Absorbs heat from space | Keeps food and air cool |

You need all these parts to work together for co2 refrigeration to do its job. If one part stops, the whole system cannot cool properly.

Remember: Good maintenance keeps your co2 refrigeration system running smoothly and helps save energy.

Unique Features and Challenges

Transcritical vs. Subcritical Systems

Transcritical co2 and subcritical systems are both used in refrigeration. Transcritical co2 systems work above the critical point. Subcritical systems work below the critical point. Each system handles pressure and temperature in different ways. Transcritical co2 systems use high pressure. They do not turn co2 into a liquid in the gas cooler. Subcritical systems let co2 become a liquid at lower pressure. Transcritical co2 is good for cooling in hot places. It also helps save more energy.

Tip: Transcritical co2 systems work well where old systems have trouble with high heat.

Efficiency and Environmental Impact

Co2 refrigeration helps the planet in many ways. Transcritical co2 systems use co2, which does not cause much global warming. Using co2 refrigeration lowers greenhouse gas emissions. These systems use smart compressors and controls to save energy. You waste less energy and pay lower bills. Many supermarkets and warehouses use co2 refrigeration for these reasons.

Feature | Benefit for You |

|---|---|

Low global warming | Less harm to the environment |

Energy savings | Lower costs |

Heat recovery | Use waste heat for hot water |

Operational Challenges

Co2 refrigeration comes with some challenges. High pressure means you need strong pipes and valves. You must check for leaks often to stay safe. You need special training to work with co2. Sometimes, co2 systems need more maintenance than older ones. You also need to watch the outside temperature. In very hot weather, transcritical co2 systems may need extra cooling.

Note: Regular checks and good training help your co2 refrigeration system work well.

Co2 refrigeration gives many benefits, but you must be careful with its special challenges. Learning how to manage these systems is a smart choice.

You now understand how transcritical co2 systems work. These systems use co2 to move heat and keep food cold. You see that co2 acts differently above its critical point. Transcritical co2 brings new features to refrigeration. You help the planet by choosing co2. You find co2 in many stores and warehouses. You learn that co2 systems need strong parts and good care. You may see more co2 systems in the future. If you want to work with modern refrigeration, keep learning about co2 and co₂. Your skills will help you and your business grow.

FAQ

What makes CO2 refrigeration better for the environment?

CO2 does not hurt the ozone layer. You use a natural gas with low warming power. Supermarkets and warehouses pick CO2 systems to lower pollution and follow green rules.

Can you use transcritical CO2 systems in hot climates?

Yes, you can use them. Gas coolers help the system work in high heat. You might need extra cooling on very hot days. Many stores in warm places use transcritical CO2 and it works well.

Are CO2 systems safe to operate?

You stay safe if you get proper training and do maintenance. CO2 systems run with high pressure. You must check for leaks and use strong pipes. Technicians learn special safety steps for these systems.

How often should you maintain a CO2 refrigeration system?

You should check your system often. Monthly checks help you find leaks and keep parts working. You save energy and stop breakdowns with regular care.

See Also

Exploring The Key Benefits Of Transcritical CO₂ Systems

Discovering The Advantages Of CO₂ Transcritical Cooling Solutions

Unveiling The Innovations In ARKREF CO₂ Refrigeration Technology

Comparing ARKREF CO₂ Refrigeration And Conventional Cooling Systems

Investigating The ARKREF CO₂ Project And Its Refrigeration Innovations