Key Factors to Consider When Buying a Low Temperature Chiller

Choosing the right low temperature chiller is very important. It helps your business work better and saves money. A good chiller keeps things cool and prevents overheating. Picking the right one for your needs avoids energy waste. It also lowers costs and makes your equipment last longer. Planning carefully saves money and boosts productivity too.

Key Takeaways

Pick a cooling capacity that fits your business needs. This saves energy and helps equipment work well.

Look at energy efficiency ratings when choosing a chiller. Better ratings mean lower power bills and help the planet.

Take care of your chiller to make it last longer. Clean filters and oil parts regularly using a checklist.

Learn about air-cooled and water-cooled chillers. Each works best depending on your space and cooling needs.

Think about the total cost, not just the price. Include energy use, repairs, and upkeep for better planning.

Cooling Capacity and Application Needs

Matching Cooling Capacity to Business Requirements

Picking the right cooling power is key for your business. A low temperature chiller must handle your specific cooling needs. If it’s too weak, it won’t keep things cool enough. If it’s too strong, it wastes energy and costs more.

To find the right size, check your equipment’s heat output. Also, think about how much cooling your process needs. For example, devices like TFTEC modules show how cooling depends on material thickness and temperature. These details affect how well the system works.

By choosing the right cooling power, you save energy and keep things running smoothly. This helps lower costs and makes your equipment last longer.

Determining Temperature Range for Process Cooling

Knowing the temperature range your work needs is very important. Different jobs need different cooling levels. For example, making medicine needs very cold temperatures. Food processing might only need mild cooling.

A low temperature chiller should keep the temperature steady for your needs. Tests can show how much power is needed to reach certain temperatures. They also check if the chiller can hold the right range.

When picking a chiller, think about the highest and lowest temperatures you need. This makes sure it can handle changes without breaking down. Good temperature control improves quality and protects your equipment.

Consequences of Incorrect Sizing

Getting the wrong size chiller can cause big problems. A chiller that’s too small might overheat and damage your equipment. This can stop your work and cost a lot to fix.

A chiller that’s too big can also cause trouble. It might turn on and off too often, wasting energy and wearing out parts. This raises costs and shortens its life.

To avoid these issues, ask experts or use tools to find the right size. A properly sized chiller works better, saves money, and avoids downtime.

Energy Efficiency and Cost Savings

Checking Energy Use and Efficiency Ratings

How much energy a low temperature chiller uses is important. Always check its efficiency ratings before buying one. These ratings tell you how well it cools while using less energy. Higher ratings mean it saves more energy and costs less to run.

Tip: Choose chillers with smart tech like DC inverter systems. These systems can reach a COP of 3.2, saving 60% energy compared to older methods.

Energy-saving chillers also help the environment by cutting greenhouse gases. This helps your business meet green goals and saves money too. Picking a chiller with good efficiency improves your work and lowers costs.

Why Glycol Helps Chillers Work Better

Glycol is often used in cooling systems to boost efficiency. It lowers the coolant's freezing point, so chillers can work at colder temperatures.

Glycol also stops parts inside the system from rusting. This keeps the chiller running smoothly for a longer time. Plus, glycol systems usually need less upkeep, saving you time and money.

Note: Be careful with glycol levels. Too much can hurt cooling, and too little won’t protect the system enough.

Adding glycol to your system makes it more efficient and helps your equipment last longer.

Saving Money with Energy-Efficient Chillers

Buying an energy-efficient chiller saves money over time. These chillers use less energy, which lowers your electricity bills. Over the years, the savings can be more than the cost of the chiller.

Energy-efficient chillers also have extra benefits. They cut greenhouse gases, improve energy use, and support better health. These perks add value beyond just saving energy.

Chillers with high efficiency ratings often last longer and break down less. This means fewer repairs and less downtime for your business. Choosing an energy-efficient chiller gives you savings now and in the future.

Maintenance and Reliability

Routine Maintenance Requirements

Taking care of your low temperature chiller keeps it working well. Follow the maker’s instructions for cleaning and checking parts. Dirt can block air filters and make cooling worse. Clean filters often to keep air moving properly.

Grease moving parts to stop damage. Check coolant levels regularly to prevent overheating. If using glycol, watch its amount to keep things efficient. Doing maintenance on time avoids sudden problems.

Tip: Make a checklist to remember all maintenance tasks.

Assessing Durability and Ease of Servicing

How strong and easy-to-fix your chiller is matters a lot. Better systems cost more at first but save money later. They last longer and need fewer repairs. Energy-saving models also cut running costs.

Look at warranties and repair options when choosing a chiller. Good warranties lower future expenses. Nearby repair services fix problems faster, reducing downtime. Maintenance plans help your chiller last longer.

Here’s a table with key points:

Aspect | Details |

|---|---|

Strong systems cost more upfront but last longer. Energy-saving models lower bills. Maintenance costs differ. Cheap units can lead to expensive downtime. | |

Warranty and Service Considerations | Good warranties save money over time. Nearby repair services fix issues quickly. Maintenance plans make equipment last longer. |

Importance of Regular Monitoring for Longevity

Watching your chiller often helps find problems early. This makes it last longer. Changes in temperature, strange sounds, or weaker cooling show issues. Fixing these quickly avoids big repair costs.

Use sensors to check things like temperature and energy use. These tools give live updates to spot problems fast. Monitoring keeps your chiller working at its best, protecting your tools and work.

Note: Watching your chiller regularly improves how it works and saves money.

Types of Low Temperature Chillers

Air-Cooled Chillers: Pros and Cons

Air-cooled chillers use air to cool the refrigerant. They are small and easy to set up. These chillers are great for places with little space. No water is needed, so installation is simpler.

But, they don’t work well in hot weather. High heat makes them less efficient. They can also be noisy because of the fans. If your business needs quiet or works in hot areas, this may not be the best choice.

Tip: Air-cooled chillers are good for small jobs or mild climates.

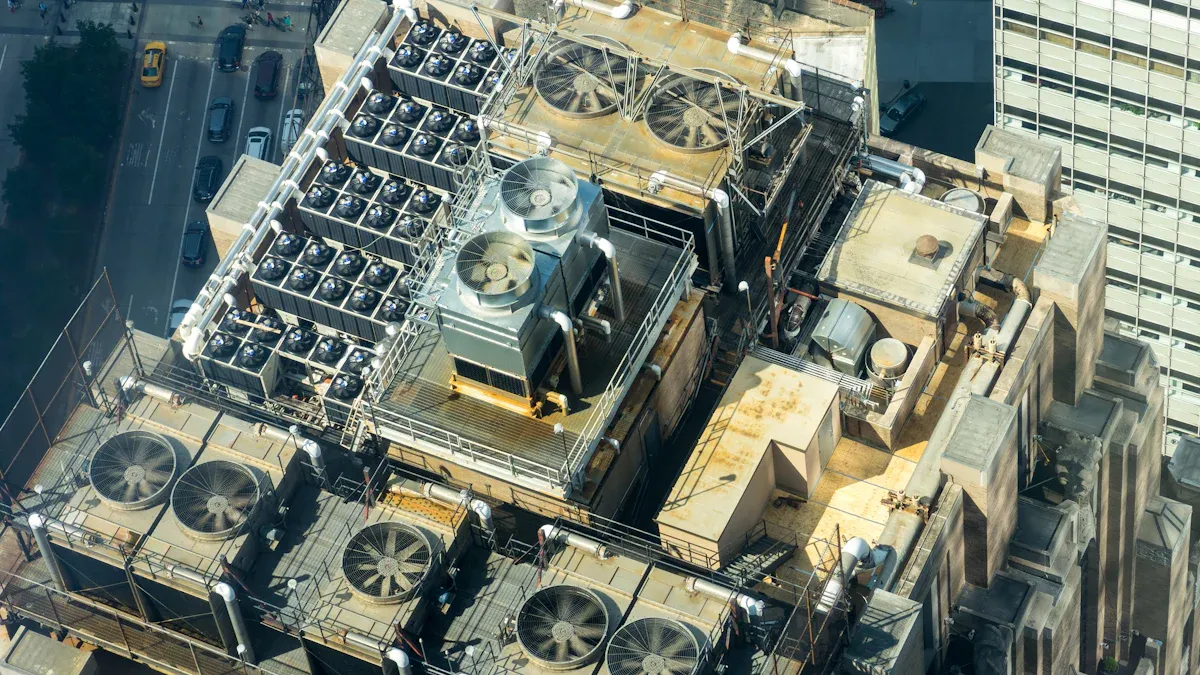

Water-Cooled Chillers: Pros and Cons

Water-cooled chillers use water to cool the system. They are more efficient, especially in hot places. Water cools better than air, so they work well in heat. They are also quieter, which is good for noise-sensitive areas.

However, they need a steady water supply and extra equipment like cooling towers. Maintenance can be harder because of rust or scaling.

Specification | Value |

|---|---|

7569W-3640W | |

Temperature Control Accuracy | ±0.1°C |

Compressor Specification | 5HP |

Flow | 20-40L/min |

Refrigerant | R404A |

Power Supply | Single phase 220V-240V/60HZ |

Safety Protection | Delay, overcurrent, overheating, phase sequence, phase loss protection |

Water-cooled chillers are best for businesses needing high cooling and water access.

Choosing the Right Type for Your Business Environment

Picking the right chiller depends on your business needs. Think about space, cooling needs, and the environment. Air-cooled chillers are small and simple. Water-cooled chillers are efficient and quiet.

Check your workspace and cooling demands. For example, think about how close the chiller is to work areas. If you need precise temperature control, water-cooled chillers might be better.

Note: Refrigeration systems work by changing the refrigerant from vapor to liquid. This process keeps cooling efficient and reliable.

By understanding your needs and space, you can pick a chiller that works best and helps your business succeed.

Installation and Space Considerations

Checking Space and Chiller Size

Before buying a low temperature chiller, check your available space. Measure the area where the chiller will go. Compare these measurements with the chiller’s size to make sure it fits. If the chiller is too big, it can cause problems and block access.

Think about the chiller’s footprint too. Some chillers are small and fit tight spaces. Others need more room to work properly. If your space is limited, choose a smaller model. This helps the chiller fit well without disturbing other equipment.

Tip: Leave extra room around the chiller for airflow and repairs. This stops overheating and makes fixing easier.

Making Sure Ventilation and Access Are Good

Good ventilation helps your chiller work better. Check if the area has enough airflow. Air-cooled chillers need clear vents to cool properly. Blocked vents can make cooling worse and use more energy.

Access is also important. Make sure workers can reach the chiller easily for repairs or cleaning. Don’t put it in tight corners or behind other machines. Easy access keeps the chiller running well and avoids delays.

Note: Bad airflow and hard-to-reach spots can shorten the chiller’s life.

Getting Help for Installation

Putting in a low temperature chiller needs careful planning. Ask experts to help with the setup. They can check your space, cooling needs, and environment. Experts can suggest the best spot and setup for the chiller.

They also make sure the installation follows safety rules and maker instructions. This lowers the chance of problems and helps the chiller last longer. Spending on expert advice now can save money later.

Reminder: A good installation plan boosts efficiency and cuts future repair costs.

Budget and Total Cost of Ownership

Balancing Upfront Costs with Long-Term Value

When buying a low temperature chiller, think beyond the price. A cheaper chiller might seem like a bargain but cost more later. High-quality chillers use less energy and last longer. These features save money on bills and repairs over time.

A reliable chiller breaks down less and avoids costly delays. This keeps your work running smoothly without surprise repair costs. By weighing upfront costs against long-term savings, you make a smarter choice.

Tip: Compare how long chillers last and their energy use to get the best deal.

Evaluating Total Cost of Ownership (TCO)

The total cost of ownership (TCO) includes more than the buying price. It also covers energy bills, repairs, and downtime. To find TCO, check how much energy the chiller uses yearly. Look at maintenance needs and part replacement costs.

For example, an energy-saving chiller may cost more now but save thousands later. A durable chiller with a good warranty also lowers repair costs. Knowing TCO helps you see the real cost and avoid surprises.

Tips for Finding Cost-Effective, High-Quality Options

Getting a good chiller doesn’t mean picking the cheapest one. Start by looking at brands known for quality and dependability. Read reviews and ask experts for advice.

Choose chillers with energy-saving features like variable speed compressors. These cut electricity costs a lot. Check for warranties and service plans that cover repairs.

Note: Buying from a trusted seller ensures you get a real product with support.

By focusing on quality and efficiency, you can find a chiller that fits your budget and works well.

Picking the right low temperature chiller needs careful thought. Match the cooling power to your needs, focus on saving energy, and keep up with maintenance for reliability. Choose the right type, plan installation well, and think about upfront costs versus future savings.

Why it matters:

Energy-efficient systems are important for a greener future.

Better cooling is needed for industries like factories and data centers.

Good chillers lower costs while staying efficient.

Look closely at what your business needs. Asking experts can help you pick the best option. A smart choice makes sure your chiller works well and saves money over time.

FAQ

1. What is the best temperature range for a low temperature chiller?

The best range depends on what you need it for. For factories or industrial use, it’s usually between -40°F and 50°F. Always check your cooling needs before picking a chiller.

2. How often should a chiller be maintained?

You should maintain your chiller every three months. This includes cleaning filters, checking coolant, and looking at moving parts. Regular care keeps it working well and avoids expensive repairs.

3. Can all chillers use glycol?

Not every chiller works with glycol. Look at the maker’s instructions to be sure. Glycol helps stop freezing and makes chillers more efficient, but using it wrong can damage the system.

4. What’s the main difference between air-cooled and water-cooled chillers?

Air-cooled chillers use fans to cool and are small and simple to set up. Water-cooled chillers use water and cooling towers, making them more efficient but harder to maintain.

5. How do you figure out the total cost of ownership (TCO)?

To find TCO, add the price, energy bills, repair costs, and downtime. Energy-saving chillers may cost more at first but save money later.

See Also

Essential Strategies to Enhance Walk-In Chiller Performance

Important Factors to Choose an Industrial Tube Ice Maker

Best Practices for Maintaining Cold Room Temperature Effectively