Understanding Low-temp Screw Parallel Units and Their Role in Industry

A low-temp screw parallel unit is a special machine. It works in places with very cold temperatures. Think of it as an important tool for accuracy and speed. It is used in industries where keeping exact temperatures matters a lot. These units help in cryogenics and LNG industries. Small temperature changes can affect how things work there. Using these units saves energy and cuts down waste. They are very important for today's industries.

Key Takeaways

Low-temp screw parallel units are important for industries needing exact temperature control, like LNG and cryogenics.

These units save energy and cut waste, helping industries work better.

Taking care of the screws, cooling parts, and seals keeps them working well and lasting longer.

These units can be used in many areas, like food and medicine, to boost work output.

New technology will make these units even better and easier for all businesses to use.

What is a Low-temp Screw Parallel Unit?

Definition and Key Features

A low-temp screw parallel unit is a machine for very cold places. It helps keep things accurate and efficient when temperatures matter. These machines are used where small temperature changes can cause problems.

The unit is strong and works well in tough conditions. It has screws that turn together to handle materials smoothly. The materials used to build it are tough and last long, even in freezing environments.

Another great thing is its flexibility. You can adjust it for different jobs, like working with LNG or other sensitive materials. Its small size makes it easy to fit into existing setups, saving space and effort.

Importance in Cryogenic and Low-temperature Applications

These units are very important in industries needing very cold conditions. For example, LNG must stay super cold to stay liquid. Without the right tools, keeping it cold is hard.

Using this unit helps control processes carefully. This is crucial for LNG transfer, where even a small heat increase can cause loss. The unit reduces waste and boosts productivity.

These machines are also key in making sensitive products. In medicine, for instance, keeping the right temperature ensures medicines work well. A low-temp screw parallel unit helps keep these conditions steady.

Tip: If your work involves cryogenics, this unit can improve efficiency a lot.

How Does a Low-temp Screw Parallel Unit Work?

Core Parts and Their Jobs

A low-temp screw parallel unit has key parts. Each part helps it work well.

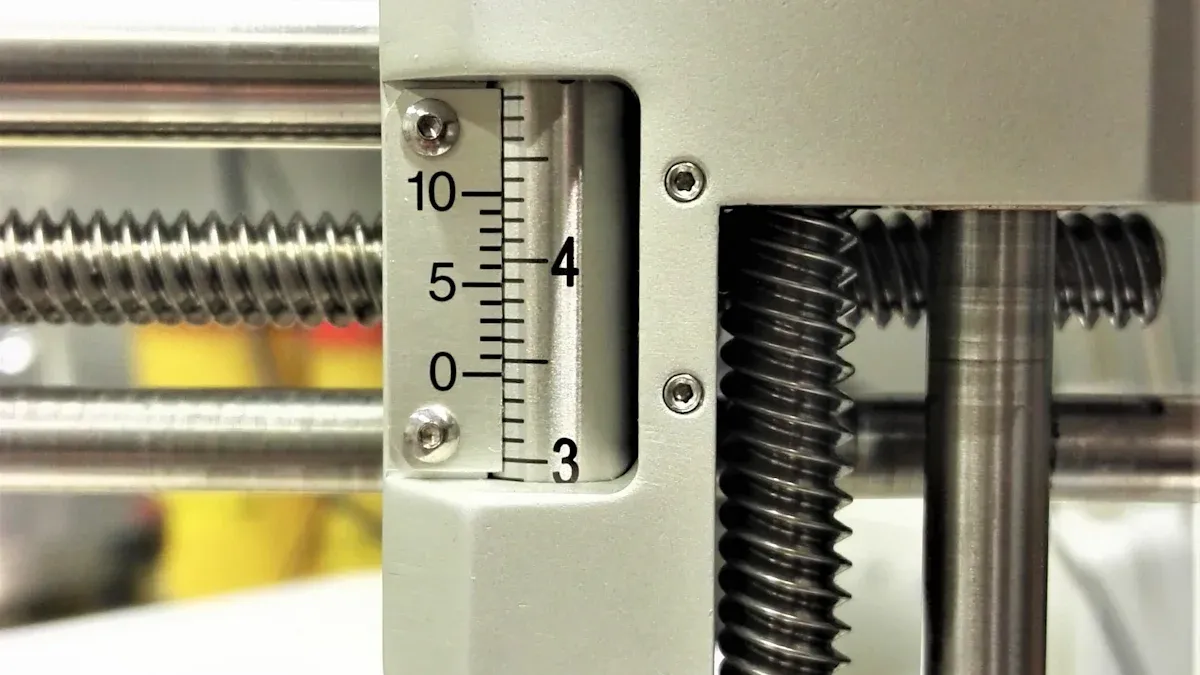

Screw Assemblies: These are the main parts of the unit. They spin together to move materials easily. Their design reduces friction, even in freezing temperatures.

Cooling System: This keeps the unit cold. It stops overheating and helps it work in very cold places.

Drive Mechanism: This powers the screws. It gives the force needed to keep materials moving.

Sealing System: This stops leaks and keeps the unit airtight. It is very important for handling sensitive things like LNG.

Control Panel: This lets you change settings like speed and temperature. It helps the unit match your process needs.

Note: All parts work together to make the unit reliable and accurate.

How It Works in Factories

The unit works in a simple but smart way. First, materials go into the unit through an opening. The screws spin and push the materials forward. The cooling system keeps the temperature steady, which is very important for exact processes.

While materials move, the sealing system stops leaks. This is crucial for industries like LNG, where leaks can cause big problems. The drive mechanism powers the screws, keeping them running smoothly. The control panel lets you watch and change the process as needed, giving you full control.

Tip: Taking care of these parts regularly helps the unit last longer and work better.

Industrial Applications of Low-temp Screw Parallel Units

Role in LNG Loading and Unloading Arms

Low-temp screw parallel units are key for LNG loading arms. These arms move LNG between tanks and transport ships. Keeping LNG cold is very important to stop it from turning into gas. Even small heat changes can cause loss and safety problems.

The unit helps materials move smoothly in the arms. Its sealing system stops leaks, which is very important for LNG. The cooling system keeps the temperature steady, so the arms work without stopping. This unit makes LNG transfers safer and faster.

Tip: Take care of the unit often to keep it working well.

Applications in Extrusion Processes

Extrusion processes use low-temp screw parallel units a lot. Extrusion shapes materials by pushing them through a mold. Industries like plastics, food, and medicine use this process. Keeping the right temperature is important for good results.

The unit’s screws help materials move evenly during extrusion. Its cooling system stops overheating, which can ruin products. You can change settings on the control panel to fit your needs. This makes the unit useful for jobs needing exact control.

Note: Using this unit in extrusion can lower waste and make better products.

Use in Cryogenic and Temperature-sensitive Industries

Cryogenic industries need low-temp screw parallel units to work well. These industries deal with very cold materials like liquid nitrogen. The equipment must handle freezing conditions without breaking.

The unit’s strong design works well in cryogenic jobs. Its sealing system stops leaks, keeping materials safe. The cooling system holds the right temperature for things like gas storage.

Industries like medicine and food also use this unit. It keeps the exact conditions needed for safe and stable products. This unit works well in tough places, making it useful for many industries.

Callout: If you work with cold or sensitive materials, this unit can help you do better work.

Other Notable Use Cases Across Sectors

Low-temp screw parallel units are useful in many industries. They work well in tough conditions and keep things precise. Let’s look at some areas where these units are very important.

1. Food Processing and Preservation

In food production, keeping the right temperature is key. These units are used in freezing systems for items like meat and vegetables. They freeze food quickly and evenly, stopping ice crystals from forming. This keeps the food’s texture and quality safe. Faster freezing also means better results and less waste.

Tip: Use these units in food processing to save time and reduce waste.

2. Chemical Manufacturing

Making chemicals often needs stable, cold conditions. These units help during chemical reactions by keeping temperatures steady. For example, they mix and move materials without adding heat. This prevents contamination and improves the final product.

3. Aerospace and Defense

The aerospace industry uses these units for cryogenic tasks. They handle materials like liquid hydrogen, used in rockets. These units keep these materials stable during storage and transfer. Their strong design makes them reliable for critical jobs.

4. Electronics and Semiconductor Industry

Electronics need exact conditions to make good parts. These units cool things during semiconductor production. They stop overheating, protecting delicate components. This helps make better products with fewer defects.

5. Environmental and Energy Sectors

These units help in energy and environmental projects. They are used in carbon capture systems to handle gases like carbon dioxide. They also help in renewable energy, such as storing hydrogen. These units support efforts to cut emissions and improve sustainability.

Callout: These units are not just tools; they help industries innovate and stay eco-friendly.

6. Pharmaceuticals and Biotechnology

Medicine production needs exact temperatures. These units handle sensitive materials like vaccines. They keep materials stable during production, improving safety and effectiveness.

7. Plastics and Polymer Industry

Plastics are shaped using extrusion processes. These units keep the right temperature and help materials flow smoothly. They are great for making high-quality polymers used in cars and medical tools.

Note: No matter your industry, these units can improve your work and save resources.

Advantages and Challenges of Low-temp Screw Parallel Units

Benefits for Efficiency and Precision

Low-temp screw parallel units help industries work better. Their special screw design moves materials smoothly, even in tough conditions. This design lowers friction, making the unit last longer and work faster. These units keep working well over time without many problems.

Another big plus is their accuracy. They control temperature and material flow very precisely. This is very helpful in sensitive jobs. For example, in cryogenic industries, small temperature changes can ruin products. The screws in these units keep materials moving steadily, avoiding mistakes.

These units also save energy by working efficiently. They reduce waste and help industries get more done. This makes them a great choice for companies wanting to save energy and stay precise.

Tip: Check the screws often to keep the unit working its best.

Challenges in Implementation and Maintenance

Even with their benefits, these units have some challenges. Setting them up in old systems can be tricky. You might need to change your setup to fit the unit. This can cost more money and take extra time.

Taking care of these units is also important but can be hard. The screws need regular checks to avoid damage. If ignored, the unit may not work as well or could break. The cooling and sealing systems also need to stay in good shape.

Training your workers to use and fix these units is key. Without training, mistakes can happen. But teaching your team can solve these problems and make things run smoothly.

Note: Fixing these issues early can save time and money later.

Real-world Examples of Industrial Use

Many industries use low-temp screw parallel units successfully. In the LNG industry, these units help during loading and unloading. Their screws move materials easily, even in freezing conditions.

The food industry also uses these units a lot. For example, frozen food makers use them to keep exact temperatures. This makes food better and reduces waste.

In medicine, these units handle sensitive items like vaccines. They keep products safe and working well.

Callout: These examples show how useful these units are in many industries.

Future Potential of Low-temp Screw Parallel Units

New Designs and Smarter Technology

Low-temp screw parallel units are getting better with new ideas. Makers are working to make them stronger and last longer in cold places. Now, they use tough materials that don’t wear out easily in freezing conditions. These materials help the units work well for a long time.

Another cool update is adding smart control systems. These systems let you watch and change how the unit works instantly. For example, sensors can spot temperature changes and fix the cooling system automatically. This means less work for people and better performance.

Smaller designs are also becoming a trend. Compact units fit into tight spaces and are easier to set up. These changes make the units more useful and simple for many industries.

Changes in LNG and Cryogenic Work

The LNG and cryogenic fields are using smarter tools to work better. Here’s a quick look at what’s new:

Key Points | Details |

|---|---|

Main Focus | |

New Ideas | Smart tech, better materials, improved docking systems |

Tech Upgrades | Lighter designs, smart controls, stronger materials |

Work Style Change | From manual work to smart, automatic systems |

Why It Matters | Makes LNG equipment more advanced and efficient |

These updates show a move toward smarter and more exact tools. For instance, smart loading arms use sensors to place themselves perfectly. This cuts mistakes and saves time. Lighter materials also make the tools easier to use, helping workers do more.

What’s Next for Industries

More industries will start using low-temp screw parallel units. These units are great at keeping things super cold while saving energy. This makes them useful in medicine, food, and energy work. As companies focus on being eco-friendly, these units will help cut waste and save power.

The need for LNG and clean energy will also push more people to use these units. Businesses will want safe tools for handling cold materials. With new updates, these units might become cheaper and easier to get. This could help smaller companies use them too, not just big ones.

Tip: Keep an eye on these changes to decide if this tech is right for you.

Low-temp screw parallel units are very important for industries. They keep temperatures steady, cut waste, and boost work output. These machines work well in tough conditions like LNG, cryogenics, and food production.

Callout: Using these units can save energy and support eco-friendly goals.

With better technology, these units will improve and be easier to use. Adding them to your work can help you stay modern and eco-friendly. Start using them now to see the benefits!

FAQ

What industries use low-temp screw parallel units the most?

Industries like LNG, cryogenics, food, and medicine use them a lot. These machines keep temperatures steady, cut waste, and make work faster. They are great for jobs needing cold or exact conditions.

How do you take care of a low-temp screw parallel unit?

Check screws, cooling parts, and seals often for damage. Clean the machine to stop dirt buildup. Teach your team how to maintain it properly. Follow the maker’s rules to keep it working well.

Are low-temp screw parallel units good for the environment?

Yes, they save energy by working smartly and cutting waste. They help industries that want to be eco-friendly, like clean energy and green projects.

Can small companies use low-temp screw parallel units?

Yes! Small designs and lower prices make them easy to use. They help small businesses work better in areas like food and medicine.

What new features do these units have?

New units have smart controls, sensors, and stronger materials. These updates make them work better, need less effort, and last longer. Smaller designs also make setup simple.

See Also

Exploring Benefits of Transcritical CO2 Refrigeration Systems

How Spiral Freezers Drive Innovation in the Industry

A Deep Dive Into Industrial Freezing Tunnel Operations

Essential Guide for Quick Freezing Compressors in Food

Comparing Spiral and Tunnel IQF Freezers: Cost and Efficiency