Everything You Need to Know About Low Temperature Chiller Manuals

A low temperature chiller manual gives you the technical details you need to operate and maintain your equipment. You find step-by-step instructions, safety precautions, and troubleshooting tips in this document. > Accurate documentation helps you keep your system running safely and efficiently. Using the manual also supports compliance and protects the environment by guiding you to use the chiller responsibly.

Key Takeaways

Always start by reading the safety section to protect yourself and your team from hazards and follow emergency procedures.

Use the manual to guide proper installation, operation, and maintenance to keep your chiller running efficiently and safely.

Follow the troubleshooting steps in the manual to quickly fix problems and reduce downtime.

Keep your manual updated and stored digitally for easy access, version control, and team sharing.

Adhere to environmental and compliance guidelines in the manual to support sustainability and meet regulations.

Manual Overview

Purpose

You rely on the manual as your primary guide for understanding your equipment. The manual explains how to install, operate, and maintain your system. It gives you clear instructions for each step. You find detailed safety information that helps you avoid accidents and protect your team. The manual also outlines the correct procedures for starting up and shutting down the chiller. You use it to learn about regular maintenance tasks, such as checking fluid levels or cleaning filters.

Tip: Always review the safety section before you begin any work. This habit helps you prevent injuries and equipment damage.

The manual also supports you in troubleshooting. When you face an issue, you can follow the step-by-step solutions provided. You save time and reduce downtime by using these instructions. The manual includes technical data, such as wiring diagrams and system specifications. You use this information to ensure your installation meets all requirements. The manual also helps you comply with industry standards and environmental regulations.

Users

You benefit from the manual if you work with chillers in any capacity. Operators use the manual to run the system safely and efficiently. Maintenance technicians follow the manual to perform routine checks and repairs. Installers depend on the manual for correct setup and configuration. Facility managers use the manual to plan maintenance schedules and ensure compliance.

Common users include:

Operators

Maintenance staff

Installers

Safety officers

Each user group finds specific sections most helpful. You may focus on daily operation, while others need technical details or safety protocols. The manual serves as a shared resource for your entire team.

Manual Contents

Safety

You must always start with the safety section in your manual. This part explains how to protect yourself and your team when working with a low temperature chiller. You find clear warnings about electrical hazards, moving parts, and chemical exposure. The manual lists the personal protective equipment (PPE) you need, such as gloves, goggles, and insulated tools. You also learn about emergency procedures, including how to shut down the system quickly if something goes wrong.

Note: Never skip the safety checks before starting any maintenance or operation. This habit keeps you and your equipment safe.

The safety section also covers environmental safety. You see instructions for handling refrigerants, especially if your system uses natural refrigerants. These guidelines help you prevent leaks and reduce environmental impact. The manual reminds you to follow local and international regulations for refrigerant handling and disposal.

Installation

You use the installation section to set up your low temperature chiller correctly. The manual gives you step-by-step instructions for site preparation, electrical connections, and plumbing. You find diagrams that show where to place each component. The manual explains how to check for proper alignment and secure all fittings.

Proper installation ensures your system runs efficiently and safely. You also see tips for minimizing energy use and reducing noise. The manual may include guidelines for using eco-friendly materials and following green building standards. These steps help you meet environmental compliance and support sustainability goals.

Operation

The operation section teaches you how to start, run, and shut down your low temperature chiller. You learn the correct sequence for turning on the system, adjusting temperature settings, and monitoring performance. The manual explains how to use the control panel and interpret system alerts.

You also find advice for optimizing energy use. The manual may suggest running the chiller during off-peak hours or adjusting setpoints to save power. You see reminders to monitor refrigerant levels and check for leaks. These actions help you maintain system efficiency and protect the environment.

Maintenance

Regular maintenance keeps your low temperature chiller in top condition. The manual provides a schedule for routine tasks, such as cleaning filters, checking fluid levels, and inspecting electrical connections. You follow these steps to prevent breakdowns and extend the life of your equipment.

The maintenance section also covers sustainability. You learn how to use natural refrigerants safely and how to dispose of old parts in an eco-friendly way. The manual may recommend using smart tools or software to track maintenance and improve data quality. This approach supports compliance with environmental standards and helps you manage costs.

Troubleshooting

When problems arise, you turn to the troubleshooting section. The manual lists common issues, such as temperature fluctuations, unusual noises, or system alarms. You follow step-by-step instructions to diagnose and fix each problem. The manual includes flowcharts and checklists to guide you through the process.

You also find tips for preventing future issues. The manual may suggest regular inspections or software updates. By following these guidelines, you reduce downtime and improve system reliability.

Specifications

The specifications section gives you all the technical details about your low temperature chiller. You see information on cooling capacity, temperature range, power requirements, and refrigerant type. The manual lists the key components, such as compressors, heat exchangers, and valves.

You also find data on system efficiency and environmental performance. The manual may include tables or charts that show how the chiller meets industry standards for energy use and emissions. This information helps you compare models and choose the best system for your needs.

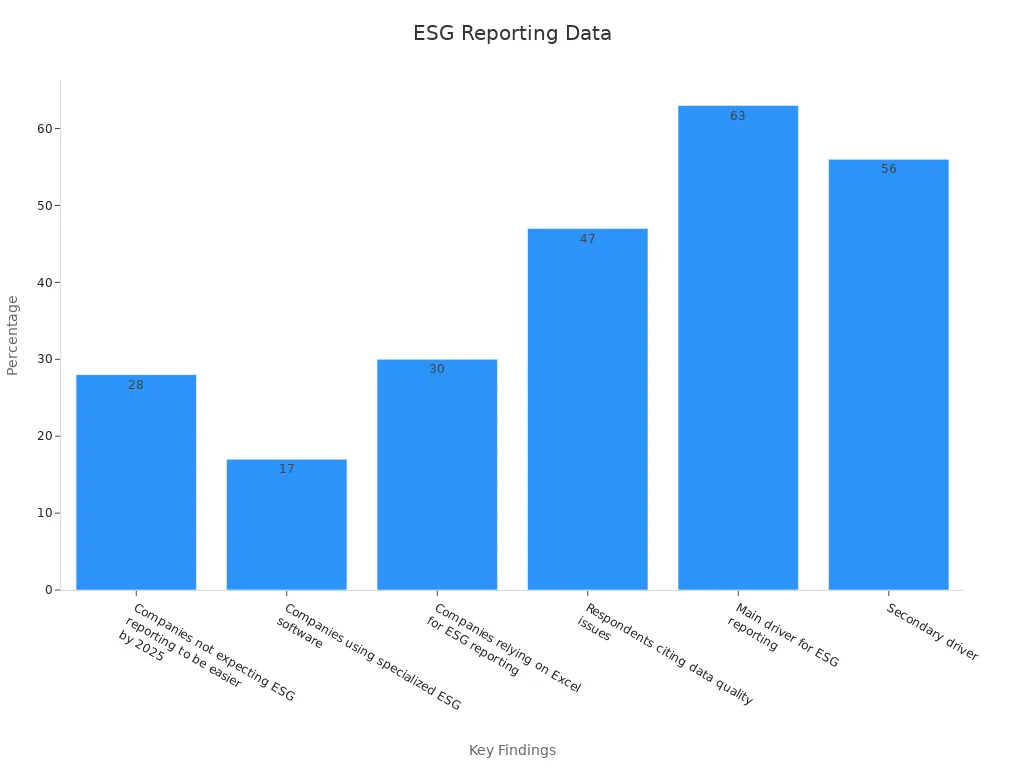

Key Finding | Data Point |

|---|---|

Companies not expecting ESG reporting to be easier by 2025 | |

Companies using specialized ESG software | 17% |

Companies relying on Excel for ESG reporting | 30% |

Respondents citing data quality issues | 47% |

Main driver for ESG reporting | Compliance (63%) |

Secondary driver | Reputation (56%) |

Leading companies integrating ESG into financial reporting and governance | Yes |

You see that sustainability and compliance are now essential parts of technical documentation. Many companies face challenges with data quality and reporting, so your manual includes guidance on using smart tools and dashboards. This helps you meet strict environmental standards and improve your company’s reputation.

ESG reporting requires you to collect accurate data from many sources.

Manual workflows and disconnected systems can cause errors.

You need adaptable tools to keep up with changing regulations.

Dashboards help you understand complex sustainability data.

Good ESG data supports efficiency, risk management, and innovation.

You benefit from a manual that covers these topics. It helps you operate your low temperature chiller efficiently, meet compliance goals, and support sustainability.

Low Temperature Chiller Components

Key Parts

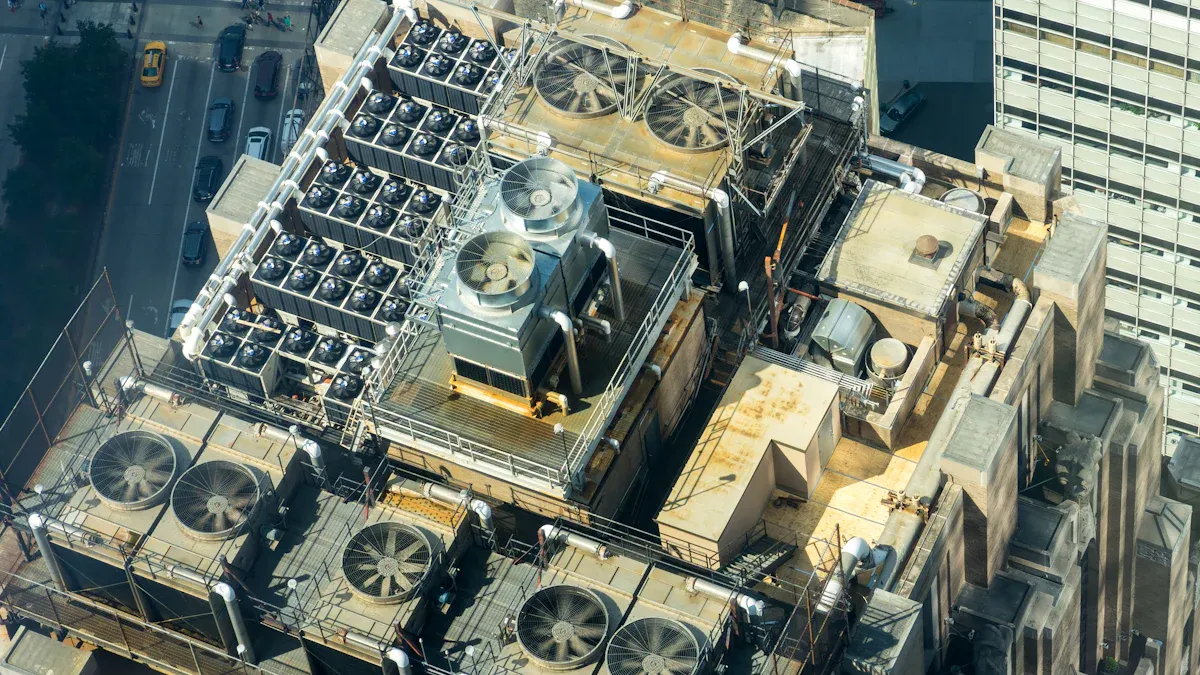

You find several critical parts inside every low temperature chiller. The compressor acts as the heart of the system, moving refrigerant through the cycle. The evaporator absorbs heat from the process or storage area, while the condenser releases that heat outside. Expansion valves control the flow of refrigerant and help maintain the correct pressure. You also see sensor probes, control units, and notification systems. These components work together to keep temperatures stable and safe.

Valves and heat exchangers play a major role in system performance. You use valves to regulate refrigerant flow and isolate sections for maintenance. Heat exchangers transfer energy between fluids, improving efficiency. The manual provides detailed diagrams and instructions for each part. You follow these guidelines to ensure proper installation and operation.

Tip: Always check the documentation for each component before starting installation or repairs. This step helps you avoid mistakes and ensures compliance with safety standards.

Refrigeration Cycle

You rely on the refrigeration cycle to achieve and maintain low temperatures. The cycle starts when the compressor draws in low-pressure refrigerant vapor. The compressor increases the pressure and temperature of the vapor, sending it to the condenser. In the condenser, the refrigerant releases heat and changes into a liquid. The expansion valve then reduces the pressure, allowing the refrigerant to cool further. The cold refrigerant enters the evaporator, where it absorbs heat from the area you want to cool.

A well-designed refrigeration cycle improves both efficiency and sustainability. Studies show that using a chilled water interconnection pipeline system for load transfer increases chiller load rates. This design reduces auxiliary power consumption and boosts overall performance. In one case, the system saved over 600,000 kWh of energy and cut carbon emissions significantly. You benefit from these design choices by lowering operating costs and supporting environmental goals.

Heat Exchange

Heat exchange is a core function in every low temperature chiller. The evaporator and condenser act as the main heat exchangers. The evaporator absorbs unwanted heat from your process or storage area. The condenser releases that heat to the outside environment. You depend on efficient heat exchange to maintain precise temperature control.

Temperature range specifications guide you in selecting and installing the right components. For example, walk-in coolers and freezers require strict temperature control to meet food safety and healthcare standards. The table below shows recommended ranges:

Storage Type | Recommended Temperature Range | FDA Requirement | Healthcare Standard |

|---|---|---|---|

Walk-in Cooler | Approximately 36°F to 38°F (2°C to 3.3°C) | Below 40°F (4°C) | 36°F to 46°F (2°C to 8°C) |

Walk-in Freezer | Approximately -10°F to 0°F (-23°C to -18°C) | At or below 0°F (-18°C) | Below -4°F (-20°C) |

You install sensor probes to monitor these temperatures. The control unit processes the data and triggers alerts if temperatures move out of range. This setup helps you prevent spoilage and maintain compliance with regulations. The manual gives you step-by-step installation guidelines for these parts, ensuring reliable operation.

Note: Always verify that your low temperature chiller meets the required temperature specifications for your application. Proper installation of sensors and controls protects your products and supports regulatory compliance.

Using the Manual

Navigation

You need to find information quickly when working with technical manuals. Most manuals use a clear structure with a table of contents, section headings, and an index. You can move through the manual by following these sections. Many modern manuals include visual aids to help you understand the layout and relationships between different parts.

Review the project structure diagram to see how all sections connect.

Use the component interaction diagram to follow the flow of information or processes.

Check the deployment architecture diagram for installation and setup steps.

Look for embedded diagrams with explanations to clarify complex topics.

Track updates by noting changes in diagrams or revision notes.

These diagrams often use standardized symbols and color codes. You can filter or group information to match your needs. This approach helps you avoid confusion and saves time.

Quick Reference

You often need answers fast. Manuals usually provide quick reference guides, tables, or summary pages. These sections highlight key data, safety steps, and troubleshooting tips. You can use bookmarks or sticky notes for the most-used pages.

Feature/Aspect | Description |

|---|---|

Diagrams update automatically to match the latest changes. | |

Structured Yet Lightweight | The manual uses a simple, clear format without extra clutter. |

Standardized Data & Output | Information stays consistent, making it easy for your team to follow. |

Version Control & AI-Friendly | Text-based diagrams work well with digital tools and version tracking. |

Custom Metadata & Flexible Views | You can filter or color-code diagrams for your specific tasks. |

Seamless Integration | You can share diagrams and guides easily with your team. |

Tip: Use the manual’s quick reference tools to reduce downtime and avoid mistakes.

Real-World Application

You apply the manual every day on the job. When you install equipment, you follow step-by-step diagrams and checklists. During maintenance, you use the troubleshooting flowcharts to solve problems. You also rely on the manual to train new staff and ensure everyone follows the same procedures.

You keep the manual updated and share it with your team. This practice helps you meet safety and compliance goals. You also improve efficiency by using diagrams and quick guides for daily tasks.

Compliance & Sustainability

Regulations

You must follow strict regulations when working with a low temperature chiller. These rules protect your team, your facility, and the environment. Many industries require you to comply with standards like GDPR, HIPAA, and PCI-DSS. You need to manage data carefully, keep records secure, and report issues quickly. Sourcetable’s AI-powered platform helps you meet these requirements by automating calculations, creating visual charts, and supporting data quality controls. You can upload data, run tests, and monitor compliance without deep technical skills.

Best practices for compliance include:

Defining who owns and manages your data.

Securing sensitive information with access controls and encryption.

Regularly auditing your processes and updating your security measures.

Training your team to spot and respond to risks.

Low-Carbon Refrigerants

You support sustainability by choosing low-carbon refrigerants for your low temperature chiller. New refrigerants like R1234yf have a global warming potential (GWP) below 1 and almost zero ozone depletion. Studies show that adding nanoparticles to these refrigerants improves system performance without changing hardware. Researchers measured key factors like efficiency and energy loss, using advanced AI models to predict results with high accuracy. These improvements help you meet environmental rules and lower your operating costs.

Nanoparticle-enhanced refrigerants boost cooling power and save energy.

AI modeling reduces the need for expensive experiments.

R1234yf stands out as a safe, effective, and eco-friendly choice.

Environmental Standards

You must meet environmental standards to operate your equipment responsibly. These standards cover refrigerant use, emissions, and waste management. You need to monitor your system for leaks, use approved refrigerants, and dispose of old parts safely. Many manuals now include guidelines for using natural refrigerants and tracking your environmental impact. You can use dashboards and smart tools to collect data and show compliance with green building codes.

Standard | Focus Area | Example Requirement |

|---|---|---|

EPA SNAP | Refrigerants | Use low-GWP, non-ozone depleting |

LEED | Building Design | Reduce energy use and emissions |

ISO 14001 | Environmental Mgmt | Track and improve sustainability |

Staying up to date with these standards helps you protect the environment and build trust with your customers.

Documentation Management

Storage

You need to store your low temperature chiller manuals in a way that keeps them safe and easy to find. Digital document management systems (DMS) offer many advantages over print manuals. You save time because you can search for documents by content, date, or author. Digital storage keeps all your manuals in one place, so you avoid losing important information. You also protect your data from security risks that come with paper files left on desks or in email threads.

Best practices for storing manuals:

Use a digital DMS to create a single source of truth for all your documentation.

Organize manuals by equipment type, location, or project.

Set up automatic backups to prevent data loss.

Store print copies in a secure, labeled location as a backup.

Tip: Digital systems with full-text search help you find what you need in seconds, saving hundreds of hours each year.

Updates

You must keep your manuals up to date. Digital systems make this easy with automatic version control. You always know which version is current, so you avoid confusion from multiple print copies. When you update a manual, everyone on your team gets the latest information right away. This reduces mistakes and helps you stay compliant with regulations.

Track changes and keep a log of updates.

Use digital workflows to notify your team about new versions.

Archive old versions for reference, but make sure only the latest is in use.

Team Access

You want your whole team to access manuals quickly and securely. Digital DMS let you set permissions, so only authorized users can view or edit documents. You can share manuals through secure portals or links, making it easy for staff in different locations to stay informed. Centralized calendaring and automated reminders help your team meet deadlines and follow maintenance schedules.

Format | Benefits | Challenges |

|---|---|---|

Digital | Fast search, secure, always up to date | Needs training, tech access |

Easy to read, no tech needed | Hard to update, less secure |

You improve efficiency and reduce errors when you use digital tools for documentation management. Training your team on these systems ensures everyone can use manuals effectively.

You gain real value by understanding and using your low temperature chiller manual. This resource keeps your team safe, boosts efficiency, and supports sustainability goals.

Review your manual often to stay current.

Store and update your documentation with care.

Seek out new manuals or technical training when needed.

Regular use of your manual helps you avoid costly mistakes and ensures your system runs at its best.

FAQ

What should you do if you lose your chiller manual?

You should contact the manufacturer or supplier for a replacement. Many companies offer digital copies on their websites. Always store a backup copy in your digital document management system.

How often should you update your chiller manual?

You should review and update your manual whenever you install new parts, change procedures, or receive manufacturer updates. Regular reviews help you keep your team safe and your system compliant.

Can you use a manual from a different chiller model?

You should never use a manual from another model. Each chiller has unique features and requirements. Always use the manual that matches your exact equipment to avoid mistakes and safety risks.

Why is it important to follow the maintenance schedule in the manual?

You protect your equipment and extend its life by following the recommended maintenance schedule. Regular tasks prevent breakdowns and help you meet safety and environmental standards.

See Also

How Water Chiller Systems Function And Operate Efficiently

Proven Strategies To Maximize Walk-In Chiller Performance

Essential Advice On Quick Freeze Compressors For Food Industry

Key Insights Into Maintaining And Caring For Cryogenic Freezers

Best Practices For Managing Temperature In Cold Storage Rooms