3 Practical Applications of the ARKREF CO₂ Transcritical Refrigeration Unit

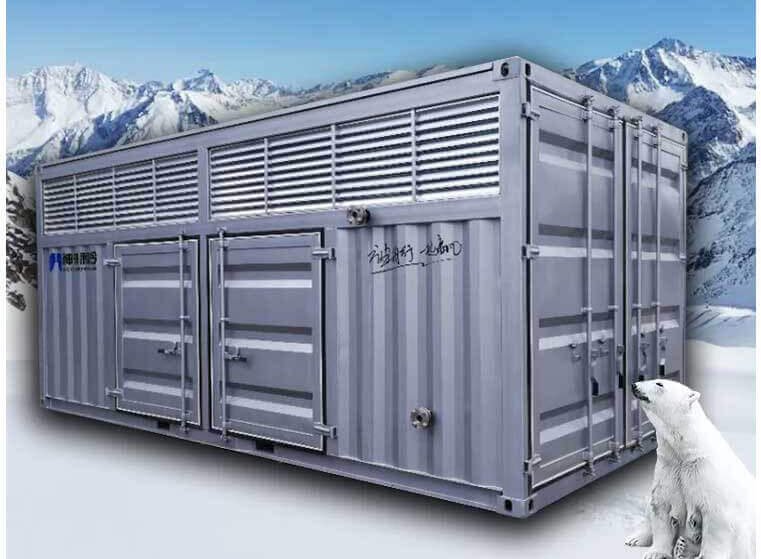

Introduction to the ARKREF CO₂ Transcritical Refrigeration Unit

The ARKREF CO₂ Transcritical Refrigeration Unit represents a cutting-edge technology in the realm of refrigeration. This innovative unit is designed to operate using transcritical carbon dioxide (CO₂) as the primary refrigerant, offering unparalleled energy efficiency and environmental benefits.

What is the ARKREF CO₂ Transcritical Refrigeration Unit?

The ARKREF CO₂ Transcritical Refrigeration Unit is a state-of-the-art refrigeration system that utilizes transcritical CO₂ as its primary refrigerant. This advanced technology is engineered to deliver optimal performance and energy efficiency, significantly reducing operational costs and contributing to lower carbon emissions. The key features of this unit include its ability to maintain consistent temperatures, enhance storage capacity, and ensure food safety in various applications.

Why CO₂ is a Game-Changer in Refrigeration

The utilization of CO₂ as a refrigerant has revolutionized the industry due to its remarkable environmental benefits, efficiency, and safety. Studies have consistently shown that transcritical CO₂ systems offer higher energy efficiency and lower environmental impact compared to traditional refrigerants. The Ozone Depletion Potential (ODP) of CO₂ is 0, and the Global Warming Potential (GWP) is 1, making it far less harmful than other synthetic refrigerants like CFCs and HCFCs. Additionally, these systems contribute to substantial reductions in greenhouse gas emissions, aligning with global sustainability initiatives aimed at combating climate change.

Environmental Benefits

By harnessing environmentally friendly CO₂ as the primary refrigerant, these advanced systems facilitate a significant reduction in carbon dioxide equivalent (CO₂e) emissions compared to conventional refrigerants. The energy-efficient design of these units minimizes overall power consumption, further contributing to sustainable practices aimed at combating climate change.

Efficiency and Safety

The ARKREF CO₂ Transcritical Refrigeration Unit offers unparalleled energy efficiency, substantial cost savings, and enhanced safety in comparison to conventional refrigeration systems. Its use of natural refrigerants ensures compliance with stringent regulations on greenhouse gas emissions while providing a reliable and efficient cooling solution for various applications.

1. Supermarket Refrigeration Systems

Supermarkets have embraced the ARKREF CO₂ transcritical refrigeration units as a game-changing solution for maintaining the freshness of perishable goods. The utilization of transcritical CO₂ in these refrigeration units ensures consistent temperatures, prolonging the shelf life of fresh produce and dairy products. By implementing these advanced systems, supermarkets benefit from extended product longevity, reduced food waste, and ultimately, enhanced customer satisfaction.

Keeping Food Fresh with ARKREF Transcritical Units

The integration of ARKREF CO₂ transcritical refrigeration units in supermarket systems has proven to be instrumental in preserving the quality and freshness of food items. These cutting-edge units create an optimal environment for perishable goods, ensuring that fruits, vegetables, meats, and dairy products maintain their peak freshness for extended periods. This not only aligns with supermarkets' commitment to offering high-quality products but also contributes to substantial reductions in food waste.

How Supermarkets Benefit

Supermarkets leveraging the ARKREF CO₂ transcritical refrigeration units experience a myriad of benefits. The prolonged shelf life of perishable goods translates to minimized losses due to spoilage, enabling supermarkets to optimize their inventory management and reduce overall operational costs. Additionally, the ability to consistently deliver fresh products enhances customer satisfaction and loyalty, further solidifying supermarkets' competitive edge in the retail industry.

Energy Efficiency and Cost Savings

The adoption of ARKREF CO₂ transcritical refrigeration units by supermarkets is not only driven by its impact on product freshness but also its remarkable energy efficiency and cost-saving capabilities. Real-world case studies have demonstrated substantial energy savings and operational benefits resulting from the implementation of these advanced refrigeration units. By significantly reducing power consumption while maintaining optimal cooling conditions, supermarkets can achieve notable cost savings and contribute to environmental sustainability simultaneously.

Reducing Operational Costs

Supermarkets are increasingly turning to ARKREF CO₂ transcritical refrigeration units as a strategic approach to minimizing operational costs. The energy-efficient design of these units directly translates into reduced electricity expenses, allowing supermarkets to allocate resources more effectively across various facets of their operations. Moreover, the long-term reliability and performance consistency of these systems contribute to lower maintenance costs, further enhancing the overall cost-effectiveness of supermarket refrigeration operations.

2. Cold Storage Warehouses

Cold storage warehouses play a pivotal role in preserving a wide range of perishable goods, necessitating advanced refrigeration solutions to maintain optimal storage conditions.

The Role of ARKREF Units in Large-Scale Storage

The ARKREF CO₂ transcritical refrigeration unit stands as a game-changing solution for cold storage warehouses, ensuring the consistent maintenance of temperatures essential for preserving perishable items. By leveraging transcritical CO₂ as the primary refrigerant, these units effectively regulate temperatures throughout the expansive storage facilities, safeguarding the quality and integrity of stored goods.

Maintaining Consistent Temperatures

Incorporating ARKREF units in cold storage warehouses is instrumental in upholding uniform temperatures critical for preserving various perishable products. The utilization of transcritical CO₂ facilitates precise temperature control across different storage zones, ensuring that items such as fruits, vegetables, and pharmaceuticals remain at their optimal conditions throughout the storage duration.

Enhancing Storage Capacity and Longevity

The deployment of ARKREF CO₂ transcritical refrigeration units brings about significant improvements in storage capacity and longevity within cold storage warehouses. These advanced units optimize storage conditions by creating an environment conducive to extending the shelf life of perishable goods while minimizing the risk of spoilage.

How ARKREF Units Improve Storage Conditions

The implementation of ARKREF CO₂ transcritical refrigeration units introduces a paradigm shift in enhancing overall storage conditions within warehouses. Through precise temperature regulation and humidity control, these units create an ideal environment for diverse products, thereby prolonging their longevity and reducing wastage significantly.

3. Food Processing and Preservation

The integration of ARKREF CO₂ transcritical refrigeration units in the food industry has revolutionized food processing and preservation operations, ensuring unparalleled levels of efficiency, safety, and environmental sustainability.

ARKREF Units in the Food Industry

The implementation of ARKREF CO₂ transcritical refrigeration units within the food industry plays a pivotal role in ensuring food safety throughout various stages of processing and preservation. These advanced units provide precise temperature control, safeguarding the quality and integrity of perishable goods. Case studies have demonstrated substantial energy savings and reductions in carbon emissions across multiple food processing facilities, highlighting the significant impact of these units on modernizing refrigeration infrastructure.

Ensuring Food Safety

The utilization of ARKREF CO₂ transcritical refrigeration units is inherently focused on ensuring food safety by maintaining optimal storage conditions and preserving the freshness of products. The enhanced system efficiency surpasses industry-standard alternatives, leading to a 40% reduction in CO₂e emissions compared to conventional refrigerants. This not only aligns with sustainable practices but also contributes to lower carbon emissions, demonstrating a commitment to environmental responsibility within the food industry.

Advantages Over Traditional Refrigeration Methods

The adoption of ARKREF CO₂ transcritical refrigeration units presents a paradigm shift from traditional refrigeration methods, offering increased efficiency and reliability in food processing and preservation operations. Substantial energy savings averaging 30% during peak operational hours have been observed across various facilities, leading to significant cost savings while minimizing environmental impact. This transition signifies a progressive approach towards modernizing refrigeration practices while prioritizing safety, efficiency, and sustainability.

See Also

Discovering the Breakthroughs in ARKREF CO₂ Transcritical Refrigeration Units

Uncovering the Advancements of ARKREF CO₂ Transcritical Refrigeration Project

Three Groundbreaking ARKREF CO₂ Transcritical Refrigeration Projects

Introduction to ARKREF CO₂ Transcritical Refrigeration Unit Case Study

Grasping the Concept of ARKREF CO₂ Transcritical Refrigeration Unit