Understanding Reefer Containers and Their Role in Cold Chain Logistics

A reefer container is a special shipping container. It keeps goods that need certain temperatures safe while moving. You use these containers to keep your cargo at the right temperature the whole time. The container has strong insulation and controls the temperature well. This protects things like food or medicine from getting too hot or cold. Many types of cargo need careful temperature control in shipping containers. Reefer containers are very important in cold chain transportation. They help move temperature-sensitive goods in global trade.

With temperature-controlled shipping, you can move cargo that needs exact temperatures. This includes things like fresh produce, dairy, or vaccines. These containers protect cargo well and help you follow strict rules for temperature-sensitive goods.

Key Takeaways

Reefer containers help keep things like food, medicine, and chemicals safe. They do this by keeping the temperature just right during transport.

These containers have strong insulation and good cooling systems. This helps keep the temperature steady. It also stops cargo from getting spoiled or damaged.

New reefers use smart technology to check temperature, humidity, and location all the time. This helps people fix problems fast if something goes wrong.

Picking the right size and type of reefer container saves money. It also keeps your cargo fresh and safe during the trip.

Reefer containers help businesses by cutting down on waste. They make things safer and let people ship perishable goods far away.

Reefer Container Basics

What Is a Reefer Container

A reefer container helps move goods that need certain temperatures. It keeps things like food and medicine safe during travel. The container has a cooling system inside. This system keeps the temperature steady. You can set the temperature you want. The container will keep it at that level. Strong insulation helps keep the cold or heat inside. This makes it different from regular shipping containers. The cooling system needs power from outside. You see these containers on ships, trucks, and trains. They are used for long trips to protect perishable items.

Tip: Check the temperature before you load your cargo. This keeps your goods safe and stops them from spoiling.

Types and Sizes

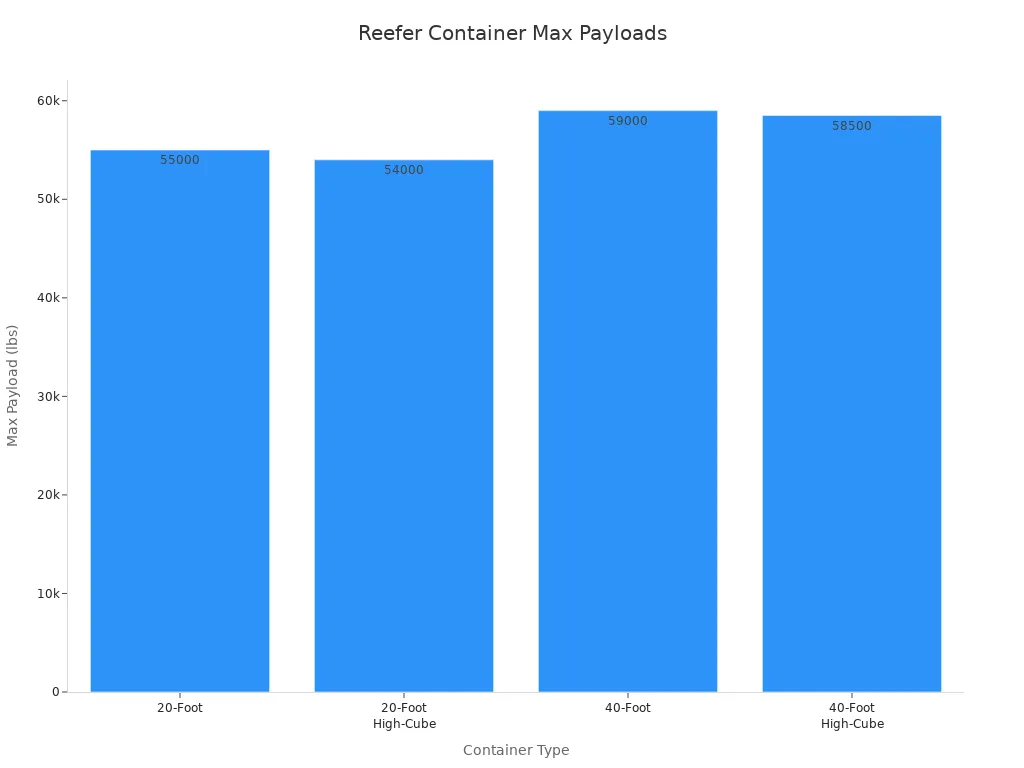

There are many types and sizes of refrigerated containers. You pick the size based on what you need to ship. The most common sizes are 20-foot and 40-foot. These sizes are used all over the world. High-cube containers are taller for bigger cargo.

Container Type | Exterior Dimensions (L x W x H) | Interior Dimensions (L x W x H) | Max Payload (lbs) |

|---|---|---|---|

20-Foot | 20' x 8' x 8'6" | 19'4" x 7'8" x 7'10" | |

20-Foot High-Cube | 20' x 8' x 9'6" | 19'4" x 7'8" x 8'10" | ~54,000 |

40-Foot | 40' x 8' x 8'6" | 39'5" x 7'8" x 7'10" | ~59,000 |

40-Foot High-Cube | 40' x 8' x 9'6" | 39'5" x 7'8" x 8'10" | ~58,500 |

Big containers carry more cargo and are good for large shipments. Small containers work for short trips or small loads. Medium containers are easy to handle and hold a fair amount. Large containers help move lots of goods far away. You have many choices for shipping with the right temperature.

Refrigerated containers follow ISO size rules. This means you can stack them and move them with forklifts. Loading and unloading is faster this way. You can use these containers for many goods, like food or chemicals. Picking the right size saves money and keeps your cargo safe.

How Reefer Containers Work

Temperature Control

Reefer containers keep your cargo safe by controlling the temperature. They use special systems to make sure it stays just right inside. You can set the temperature from +25°C to -25°C. This helps protect things like fresh food, dairy, and vaccines. The cooling system uses both active and passive thermal packaging. Phase-change materials help keep the temperature steady, even if the weather changes fast. Modern reefers have tools that let you check the temperature, humidity, and location in real time. Telematics and GPS devices send you updates. Data loggers inside the container record details about the environment. You can look at these records to make sure everything is safe. It is important to keep the cooling equipment in good shape. Regular checks and calibration help keep the temperature exact. You must also follow rules for loading and handling. This means pre-conditioning packaging and vehicles, loading the right way, and having backup plans. These steps stop thermal shock and keep your goods in good condition.

Tip: Always teach your staff and follow rules like GDP, HACCP, FSMA, and IATA Perishables Regulations. This keeps your cold chain strong and your cargo safe.

Insulation

Insulation is very important in reefer containers. It helps keep the inside temperature steady, even if it is hot or cold outside. Marine insulation materials stop heat from moving in or out. They also help keep the container safe from fire. These materials help you keep the temperature the same and protect your cargo. Good insulation also saves energy and money.

Insulation Material | Key Properties and Effectiveness |

|---|---|

Spray Foam Insulation | High R-value, great at sealing air, blocks moisture and vapor, fills cracks and gaps, very good at stopping heat transfer. Needs a pro to install and costs more at first. |

Rigid Foam Boards (Polyiso, EPS, XPS) | Good R-value, easy to cut and put in, good for DIY, but does not seal air by itself and needs extra sealing to be airtight. Works well at stopping heat transfer if sealed right. |

Mineral Wool (Rockwool) | Stops fire and noise, resists water, lower R-value than spray foam, cannot block vapor alone, needs a vapor barrier. Works okay for stopping heat transfer. |

Fiberglass Batt Insulation | Cheap, used a lot in buildings, needs careful work to stop moisture problems from steel condensation. Does not work as well if moisture is not controlled. |

You need to insulate the floors and ceilings of your reefer. Steel lets heat and cold move fast, so insulation here is important. This keeps your cargo safe and helps control the temperature. Using the right insulation lowers the chance of spoilage for sensitive goods.

Power Supply

Reefer containers need steady power to keep the cooling system working. You plug them into outside power during trips and storage. Ships, trucks, and trains give electricity to the container. When moving cargo, you use portable generators or plug into dock power. This keeps the temperature steady and protects your cargo.

You should check the power supply before every trip. If the power stops, the cooling system will not work, and your goods can spoil. Many reefers have backup systems to help avoid this. You also use dock shelters, fast roll doors, and temperature-controlled areas when loading and unloading. These steps help keep the temperature right and your cargo safe.

Note: Always watch the power supply and cooling system. This helps you find problems early and keeps your cargo safe from temperature changes.

Features of Refrigerated Containers

Monitoring Technology

Modern refrigerated containers use smart systems to watch your cargo. These systems check the temperature and air all the time. You get updates about your cargo right away. The technology can see every change inside the container. You can look at live screens and reports. If the temperature or humidity goes too high or low, you get a warning fast. These warnings help you fix problems before food or medicine spoils. The system can guess when your cargo might be in danger. This lets you act early and keep things safe.

Real-time monitoring lets you see your cargo’s temperature all the time.

It checks the air and keeps your goods safe and follows rules.

Important numbers are saved for easy reports.

Warnings and guesses help you fix problems early.

Acting fast keeps your cargo good and stops waste.

Tip: Use real-time monitoring to watch your refrigerated cargo and waste less.

Energy Efficiency

Refrigerated containers now use systems that save energy. Many reefers have compressors that control temperature well. These work even when it is very hot or cold. The compressors help keep your cargo at the right temperature and use less power. Some containers have smart tools like IoT and telematics. These let you check and control your cargo from anywhere. New insulation and green refrigerants help save energy and lower pollution. Some containers use electric or hybrid power. These are quieter and cleaner for city trips.

Green cooling and natural refrigerants like CO2 and ammonia help the planet.

Digital tools and sensors help you use less energy.

Better insulation keeps cargo cold longer and saves power.

Durability

Refrigerated containers are made to last in tough places. They use strong steel that does not rust easily. Special coatings protect them from salt and sun. The frame has strong beams and corners for heavy loads. These containers follow strict safety rules. Fire insulation and mold-proof materials give extra safety. You can stack them easily because of their design. Thick insulation keeps cargo safe from heat, cold, and loud sounds.

Strong steel frames and special coatings make containers last longer.

Fire insulation and doors that close by themselves keep cargo safe.

Good design and strong materials mean less fixing and safe cargo.

Note: Durable refrigerated containers help you save money and keep your cargo safe on every trip.

Reefer Applications

Reefer containers help move things that spoil, like food, medicine, and chemicals. You can see these containers on ships, trains, and trucks. They also work in warehouses and at distribution centers for cold storage. Using the right reefer keeps your cargo safe and fresh from start to end.

Food and Beverage

Refrigerated containers move fruits, vegetables, dairy, meat, and seafood. They keep food cold so it stays safe and tastes good. Reefers stop fruits and veggies from going bad. Many companies use refrigerated trucks to bring food from farms to stores. You can also use reefers for drinks like milk, juice, and wine. The steady cold stops bacteria and keeps flavors strong. Reefers help you follow food safety rules and waste less food.

Tip: Load produce fast into refrigerated containers to keep it cold and fresh.

Pharmaceuticals

Reefers are important for moving vaccines, insulin, and other drugs. You must keep these between 2-8°C to keep them strong. Reefer containers give you exact temperature control and live tracking. You can watch your cargo with GPS and sensors. Many trucks use wool insulation to keep medicine safe if power goes out. Wool soaks up water and stops damage from wetness. You must follow strict rules when shipping medicine. These include:

Following Good Distribution Practice (GDP) and FDA rules.

Using checked temperature control for each drug type.

Watching with GPS and sensors for quick warnings.

Training workers in cold chain safety.

Keeping strong security and clear records.

Having backup plans for problems.

Meeting customs and border laws.

Checking equipment often.

Keeping logs for checks.

These steps keep drugs safe and stop costly recalls. You also protect people by making sure medicine works right.

Chemicals

Refrigerated containers move chemicals that change with heat or cold. Some chemicals need steady temperatures to stay safe. Reefers help stop leaks, spoilage, or bad reactions. Companies use refrigerated trucks for short trips and reefers for long trips. You can store chemicals in reefers at ports or factories. This keeps cargo safe until you need it. With the right reefer, you lower risks and follow safety rules for chemical shipping.

Note: Always check the temperature and condition of your refrigerated containers before loading chemicals.

Reefers help many industries by keeping food, medicine, and chemicals safe. You can trust refrigerated containers for moving perishable goods, medicine, and chemicals. They work on ships, trucks, trains, and in storage, making your supply chain strong and safe.

Benefits and Trends

Business Advantages

Reefer containers give your business many good things. They keep goods at the right temperature. This lets you move food and medicine far away. You can use them on ships, trucks, or trains. This makes it easy to connect your supply chain. Your cargo stays safe from start to finish.

Reefer containers help stop goods from spoiling. You can check the temperature with sensors any time. If something is wrong, you get an alert fast. This helps you act quickly and protect your cargo. These tools also help stop theft and keep things safe. When you use reefers, you can:

Find out if someone opens the doors or moves the load.

Use data to pick safer routes and avoid danger.

Share info with partners and customers to work better.

Save money by cutting down on waste and delays.

Tip: Reefer containers help you keep products fresh, meet what customers want, and save money.

Future Innovations

Reefer technology is getting better every year. New products help you save energy and protect nature. Many companies use smart sensors and green refrigerants now. You can see some new ideas in the table below:

Product/Technology | Key Features and Innovations |

|---|---|

OptimaLINE | Advanced temperature control, up to 26% energy savings, reduces carbon footprint. |

PrimeLINE | Reliable, energy-saving refrigeration unit. |

NaturaLINE | Uses natural CO₂ refrigerant, ultra-low global warming potential, high recyclability. |

Variable Frequency Tech | Improves energy efficiency and performance. |

Electric Refrigeration | Supports sustainability with electric power. |

There are also new trends like AI that helps fix problems before they happen. Blockchain helps you track cargo safely. Some reefers keep vaccines very cold. IoT sensors give you updates on temperature and humidity right away. These tools help stop spoilage and keep cargo safe. In some places, governments help with digital cold chain and solar storage. These changes help you reach more people and keep up with the need for fresh, safe goods.

Note: New reefer containers will help you run a smarter, greener, and safer cold chain.

Reefer containers help keep goods safe when they need certain temperatures.

You can control the temperature very closely, usually within half a degree. This stops food, medicine, and chemicals from going bad.

Good insulation and strong cooling systems keep things fresh and safe.

You can watch your cargo in real time. There are strict rules to follow so products stay good.

New tools like smart sensors and AI make reefers work better. These new ideas help you build a safer and cleaner supply chain. Reefers are important when you ship goods all over the world.

FAQ

What goods can you ship in a reefer container?

You can move things like fruits, milk, meat, fish, medicine, and chemicals. These containers keep items at the right temperature. This helps stop your goods from spoiling or getting ruined.

How do you set the temperature in a reefer container?

You use the control panel on the container. Pick the temperature your cargo needs. The system keeps it steady for the whole trip.

Can you track your cargo inside a reefer container?

Yes! New reefers have GPS and sensors inside. You get updates about temperature, humidity, and where your cargo is. This helps you act fast if something changes.

How do you power a reefer container during transport?

You plug the container into a ship, truck, or train for power. For short stops, you can use a small generator. Always check the power before you move your cargo.

What should you check before loading a reefer container?

Make sure the container is clean and dry.

Set the right temperature for your cargo.

Check the insulation and door seals.

Test the monitoring system to see if it works.

Tip: Always look over your container before loading to keep your cargo safe.

See Also

Seven Leading Advances Transforming Cold Storage Logistics

Best Cold Room Producers Serving The Logistics Industry

Comparing Container Cold Rooms With Conventional Storage Methods

A Clear Guide To How Cold Rooms Operate Effectively

Complete Overview Of ARKREF CO₂ Transcritical Refrigeration Systems