How to Select the Best Modular Cold Room for Your Business

Choosing the right modular cold rooms is crucial for maintaining product freshness and ensuring your business operates smoothly. A well-designed modular cold room reduces food waste, saves time, and lowers costs. Food businesses can increase their earnings by up to 25% with effective cold storage solutions. When selecting the best modular cold room, consider factors such as size, temperature settings, and energy efficiency. Additionally, you can customize these cold rooms to suit your specific needs, allowing them to adapt as your business grows and comply with industry regulations.

Key Takeaways

Know how much storage you need. Think about daily use and future growth.

Pick the right temperature. Different items need certain temperatures to stay fresh.

Focus on saving energy. Good insulation and smart controls can cut energy costs by 30%.

Think about future needs. Choose cold rooms that can grow with your business.

Follow safety rules. This keeps products safe and earns customer trust.

Understanding Your Business Needs

Picking the right modular cold rooms starts with knowing your business needs. This helps you make smart choices that match your goals. Below are three important things to think about when choosing a cold room.

Checking Storage Space

First, figure out how much storage space you need. Think about how many products you handle daily and during busy times. For example, a restaurant might need less space than a food distributor. If the cold room is too big, it wastes energy. If it’s too small, it messes up inventory. To avoid problems, calculate storage based on product use and future growth.

Knowing Temperature Needs

Different items need different temperatures to stay fresh. Frozen foods need below 0°F, while fresh produce stays best between 32°F and 41°F. Know what your products need and pick a cold room with good temperature controls. This keeps items fresh and meets industry rules. Also, decide if you need one temperature or multiple temperature zones for your products.

Preparing for Growth

Your business might grow, so plan for more storage later. Modular cold rooms can expand as your business grows. The modular cold storage market could reach $12.5 billion by 2025, growing 12.5% yearly since 2019. This shows more businesses want flexible storage. A modular design helps you adjust to changes and avoid expensive upgrades.

Tip: Plan ahead when picking a cold room. A flexible option saves money and keeps your business strong.

Key Features of Modular Cold Rooms

Insulation and Energy Efficiency

Good insulation is key for cold room performance. It keeps temperatures steady and lowers energy use. Without it, energy bills can rise quickly. For instance, natural gas use went from 438.2m³ to 535.9m³ in poorly insulated spaces. But better insulation cut it to 269.7m³, nearly half. This shows how insulation saves energy and money.

Choose modular cold rooms with strong insulation like polyurethane or polystyrene. These materials keep heat out and products fresh. They also help reduce utility costs. Check and maintain insulation often to keep it working well. Regular care ensures your cold room stays efficient for years.

Temperature Control Systems

Modern temperature controls are crucial for product quality. They let you set exact temperatures to keep items fresh. Advanced systems in modular cold rooms can cut energy costs by 25% in hot areas. They also stop temperature swings that harm equipment and shorten its life.

Some systems have zones for different temperatures. This is great for storing frozen goods and fresh produce separately. Keeping systems organized and maintained can extend their life by 30%. This saves money over time and protects your investment.

Shelving and Layout Options

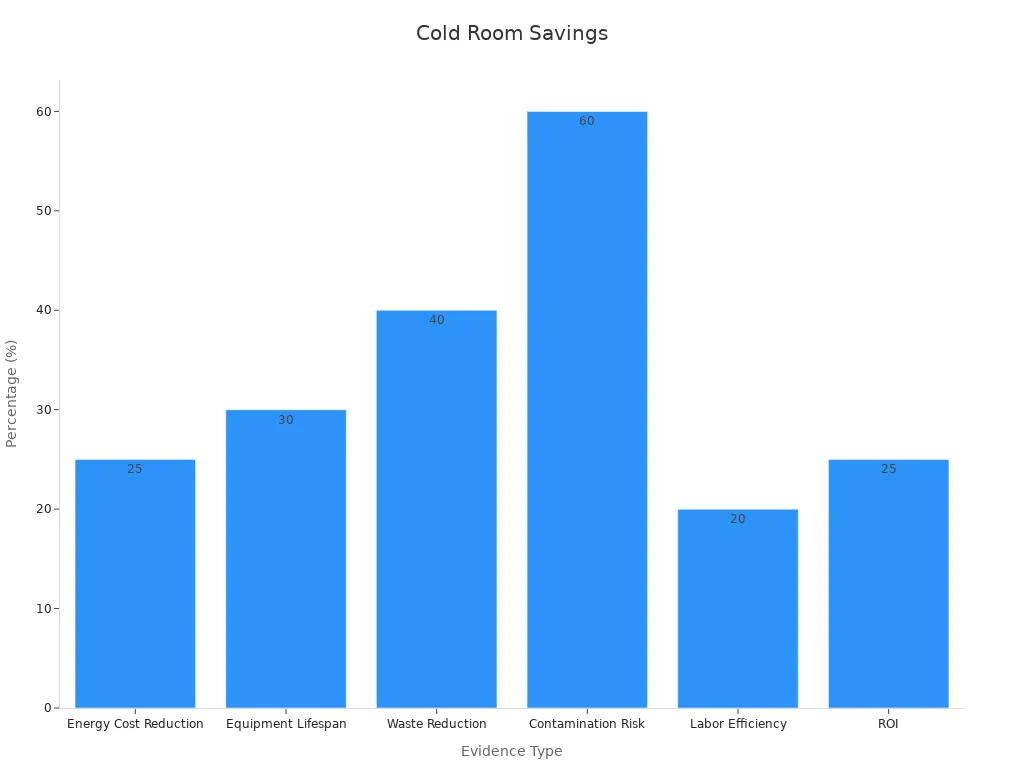

Smart shelving and layouts make storage easier and save space. Organized setups can cut energy costs by 25% and lower contamination risks by 60%. Separating raw and cooked items helps keep food safe. Zoning can also save 20% of labor time during restocking.

Use pallet racks for stacking or mezzanine racks for vertical space. Drive-in or drive-through racks reduce aisle space and increase capacity. One manager said reorganizing their cold room cut energy bills by 18% in a year. Good shelving and layouts save space and improve efficiency.

Accessibility and Lighting

Accessibility and lighting are important for modular cold rooms. A good design helps you reach items quickly and safely. It also keeps storage conditions ideal. Proper lighting and easy access improve work efficiency. They also help meet health and safety rules.

Why Accessibility is Important

Good accessibility saves time when getting items. It also reduces temperature changes. Opening the cold room often can cause uneven cooling. Organized zones stop this and keep products fresh. For example, placing popular items separately from stored goods reduces movement. This setup also keeps food safe by holding steady temperatures.

Importance of Lighting

Lighting is very important too. Bright, energy-saving lights make finding items easier. LED lights are great for modular cold rooms. They give off less heat than regular bulbs. This helps keep the cold room cool. LEDs also use less energy, cutting costs.

Standards and Tips

To meet industry rules, maintain your cold room and design it well. The table below shows key tips for lighting and access:

Feature | Benefit |

|---|---|

Lighting | |

Accessibility | Organized zones stop temperature changes, keeping food safe. |

Standards | Maintenance ensures health and safety rules are followed. |

By focusing on lighting and access, your cold room will work better. These features save money, protect products, and follow regulations.

Compliance and Rules for Temperature-Controlled Storage

Following Health and Safety Rules

Following health and safety rules keeps products safe and workers protected. Groups like the U.S. FDA, OSHA, and CDC give clear rules for handling items needing specific temperatures. These rules stop contamination, spoilage, and workplace dangers. For example, good ventilation and safety gear in cold rooms help prevent frostbite and hypothermia for workers.

Sticking to global cold chain safety rules also keeps products in good condition. This reduces waste and ensures customers get high-quality goods. Regular checks and inspections can find risks and help you follow the rules. By focusing on safety, you protect your workers and your business reputation.

Rules for Different Industries

Each industry has its own storage rules for temperature-sensitive items. For example, the pharmaceutical industry uses GDP (Good Distribution Practice) rules to keep medicines safe during storage and transport. Groups like the FDA and EMA require strict temperature checks to protect product quality.

In the food industry, following food safety rules is very important. Proper storage stops contamination and spoilage, keeping food safe to eat. Following these rules not only avoids legal trouble but also builds customer trust.

Here are some important rules to follow:

Follow FDA and CDC rules for storing perishable items.

Use GDP standards for storing medicines.

Check temperatures often to meet industry rules.

Keeping Records and Getting Certifications

Keeping good records and certifications is key to following the rules. Accurate logs of temperatures, maintenance, and safety checks show you care about meeting standards. These records also help during audits.

A study found 94% of compliance officers think good records are crucial. But too much paperwork can slow things down. To avoid this, keep records simple and clear. Review local rules often and work with experts to create better practices.

The table below shows why records matter and how they help:

Record Type | Why It Matters |

|---|---|

Misunderstanding Rules | 94% of officers say clear records help meet rules. |

Clearing Up Myths | Fixing wrong ideas improves rule-following and saves time. |

Evidence-Based Practices | Regular reviews improve compliance and cut waste. |

By staying organized and learning the rules, you can follow them easily and avoid big fines.

Energy Efficiency and Cost Benefits

Energy-Saving Features

Energy-saving features in modular cold rooms help cut costs. They also keep products fresh and safe. Features like better airflow and smart systems stop temperature changes. This protects compressors and lowers energy use. For example, a neat layout can save 25% on energy bills. Bright LED lights make it easier to see and give off less heat. This reduces waste by 40%.

Zoned shelving is another helpful feature. It lets you store items by their temperature needs. This saves 20% of labor time during inventory checks. Rearranging your cold room can also save money. Some businesses cut energy bills by 18% in one year after making changes.

Energy-Saving Feature | Measurable Impact |

|---|---|

Organized Layouts | Saves up to 25% on energy costs |

Efficient Systems | Stops temperature changes |

Optimized Airflow | Protects compressors |

Bright Lighting | Reduces waste by 40% |

Zoned Shelving | Cuts labor time by 20% |

Reorganization Impact | Lowers energy bills by 18% |

Long-Term Operational Savings

Using energy-efficient practices saves money over time. These practices lower energy bills and make equipment last 30% longer. They also cut food waste by 40% and reduce contamination risks by 60%. This improves product quality and keeps customers happy.

Better inventory control with energy-efficient designs saves 20% of labor time. This boosts how well your business runs. Food businesses can earn 25% more by using these solutions. The chart below shows how energy-efficient practices save money.

Balancing Initial Investment with Efficiency

Energy-efficient cold rooms may cost more at first. But they save money in the long run. Energy savings can cut costs by 30%, making them a smart choice. Less food waste and lower labor costs also add to savings.

When picking a cold room, think about upfront costs and future savings. High-quality insulation, advanced controls, and energy-saving features are worth it. They keep your cold room efficient and cost-effective. This helps your business grow and supports eco-friendly practices.

Statistic Description | Value |

|---|---|

Energy cost savings for businesses | Up to 30% |

Return on investment for food businesses | Up to 25% |

Cost reduction in activity | Up to 25% |

Energy bill reduction after reorganization | 18% in one year |

Focusing on energy efficiency saves money and creates a reliable storage system.

Customization and Scalability of Modular Cold Rooms

Matching Your Business Needs

Customizing modular cold rooms helps your business save money and work better. You can design the space to fit your needs, making storage and workflows easier. For example, adjustable shelves and zones let you store items by temperature. This makes managing inventory simple and reduces food waste. A café in Dubai saved 30% on costs by improving airflow and insulation.

Think about what your products and processes need when designing your cold room. You might need separate areas for frozen and fresh items or energy-saving lights to cut heat. Customizing your cold room improves product quality and safety while saving money.

Adjusting to Changing Needs

Your business needs may change over time. Modular cold rooms are flexible and can grow with your business. Features like energy-saving designs, smart zones, and modular setups make it easy to expand. For example, kitchens use zones to stop cross-contamination, while bakeries add storage as they grow.

These cold rooms also help your business run smoothly. Good layouts improve airflow, cutting waste by 40%. Regular maintenance keeps equipment working longer and avoids breakdowns. This makes modular systems perfect for businesses that need to adapt to changes or busy seasons.

Adaptation Type | Benefits | Example Use Case |

|---|---|---|

Energy-saving designs | Cuts energy bills by up to 25% | Dubai supermarkets |

Smart zones | Stops cross-contamination and keeps food safe | Commercial kitchens |

Modular setups | Easy to expand for growing businesses | Bakeries and catering services |

Regular maintenance | Avoids breakdowns and extends equipment life | All refrigeration setups |

Good layouts | Improves airflow and reduces waste by 40% | Food distributors in Abu Dhabi |

Preparing for Growth

Planning for growth is important when choosing modular cold rooms. The market for these systems is expected to reach $12.5 billion by 2025, growing 12.5% each year since 2019. This shows more businesses want flexible storage options. Modular systems let you change setups without expensive renovations.

These systems are great for growing businesses. They allow you to add storage space without stopping operations. This flexibility keeps workflows smooth and handles more inventory. By planning ahead, you avoid costly upgrades and keep storage affordable.

Tip: Pick modular cold rooms with adjustable setups for future growth. This choice keeps your business ready for changes and competition.

Common Mistakes to Avoid

Picking the Wrong Size

Choosing the wrong size cold room causes problems and extra costs. A small cold room can’t hold all your products. This may lead to spoilage or delays in operations. A large cold room wastes energy and raises utility bills. To avoid this, figure out how much storage you need. Think about your inventory and busy times. Plan for future growth too. Modular designs let you add space later. This saves money on big upgrades.

Tip: Measure your space and ask experts for advice. They can help you pick the right cold room size.

Skipping Compliance

Not following rules can lead to fines or business closure. Groups like the FDA and OSHA have strict storage rules. These rules keep products safe and high-quality. Ignoring them can spoil goods and upset customers. Learn the rules for your industry and keep good records. Regular checks can find and fix problems early.

Note: Following rules isn’t just about avoiding trouble. It also builds trust and keeps your products safe.

Forgetting Energy Efficiency

Ignoring energy efficiency raises your costs. Poor insulation and old systems use more energy. Bad layouts also waste energy. Use LED lights, better controls, and good insulation to save up to 30% on bills. These upgrades last longer and save money. Regular care keeps systems working well and avoids breakdowns.

Reminder: Saving energy isn’t just cheaper. It also helps the environment and makes your business sustainable.

Not Planning for Business Growth

Not planning for growth can hurt your business and cost money. When picking a modular cold room, think about future needs too. Many businesses don’t realize how fast their storage needs can grow. This mistake often leads to expensive fixes or work delays.

First, think about how your business might grow. Look at things like busy seasons, new products, or entering new markets. For example, a bakery might need extra space during holidays. A pharmaceutical company may need more storage for new medicines. By planning ahead, you can choose a cold room that fits your changing needs.

Modular cold rooms are flexible, but only if you plan well. Pick a design that’s easy to expand. Features like adjustable shelves, removable panels, or multi-temperature zones help. These make it simple to add space without replacing the whole system. A good setup saves money and keeps your business running smoothly as it grows.

Not planning for the future can also waste energy. A small cold room may lead to overstocking, causing uneven cooling and higher bills. A large cold room wastes energy and raises costs. Planning ahead helps you find the right size, keeping storage efficient and affordable.

Tip: Talk to experts when designing your modular cold room. They can help you create a system that works now and grows with your business.

Choosing the right modular cold rooms helps your business run smoothly. It keeps products fresh and ensures efficient operations. Knowing your storage needs is important for making smart choices. Focus on features like energy efficiency and following rules to save money. These features also improve how your business works. Custom designs let you adjust as your business grows. This keeps your business flexible and ready for changes.

Tip: Talk to experts when planning your modular cold room. They can help you avoid mistakes and get the best results for your business.

FAQ

What is a modular cold room?

A modular cold room is a storage space that keeps items cool. It is built using ready-made panels and can be adjusted in size and design. These rooms are perfect for businesses like food, medicine, and shipping.

How do I choose the right size for my cold room?

Figure out how much space you need for your products. Think about busy times and how your business might grow. Modular cold rooms can expand, so pick a size that works now and later.

Are modular cold rooms good for saving energy?

Yes, they are! Modular cold rooms have features like strong insulation, LED lights, and smart temperature controls. These help save energy, lower bills, and keep items at the right temperature.

Can I design a modular cold room to fit my business?

Yes, you can! Modular cold rooms let you add things like movable shelves, areas with different temperatures, and custom layouts. This makes storing and organizing your products easier and more efficient.

Do modular cold rooms follow safety rules?

Yes, they do. Modular cold rooms keep the right temperatures and use safe materials. Regular checks and keeping good records help meet rules like FDA or GDP standards for safety and quality.

Tip: Work with experts to create a cold room that fits your needs and follows the rules.

See Also

Choosing The Ideal Walk-in Cold Storage Solution

Leading Cold Storage Providers For Your Logistics Needs

Determining Whether A Cold Room Or Freezer Fits You