Shell and Tube Condenser Versus Plate Heat Exchanger

Choosing the right heat exchanger is very important for good performance in factories and businesses. Knowing how a shell and tube condenser differs from a plate heat exchanger helps you decide better. These systems vary in how well they work, space they need, how easy they are to fix, and how they can grow with needs. A shell and tube heat exchanger is strong and lasts long. A plate heat exchanger is small and works well with heat. By looking at these points, you can pick the best condenser for your needs.

Key Takeaways

Pick a plate heat exchanger for better efficiency. Its design moves heat quickly, saving energy.

Use a plate heat exchanger in small spaces. Its small size fits tight spots, perfect for limited areas.

Choose a plate heat exchanger for simple cleaning. You can take it apart and clean it fast.

Go for shell and tube condensers for tough jobs. They work well under high pressure and heat, great for heavy use.

Plan for growth with plate heat exchangers. Add or remove plates to change capacity as needed.

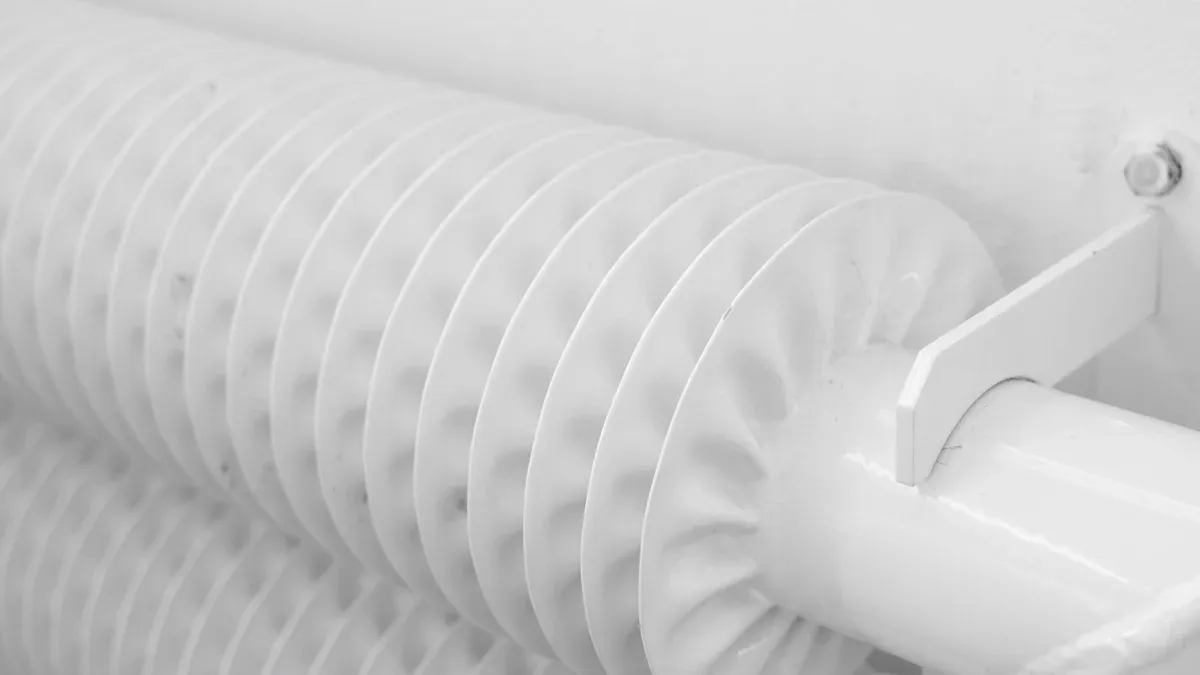

Overview of Shell and Tube Condensers

Design and Structure

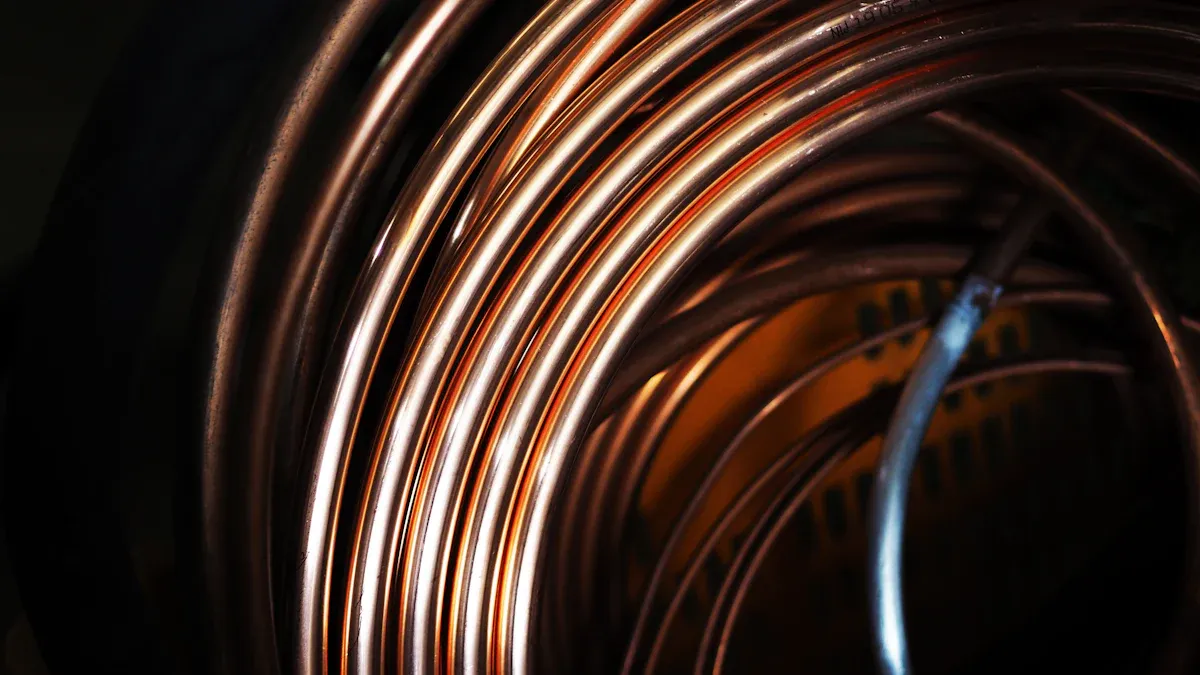

A shell and tube condenser has a round shell with tubes inside. The shell holds the fluid to be cooled, while the tubes carry cooling fluid. Heat moves between the fluids without mixing them. This design is strong and handles high pressure and heat well. It works great for tough industrial jobs. Materials like stainless steel or copper make it last long and resist rust.

Functionality and Working Principle

This heat exchanger moves heat from one fluid to another. Steam enters the shell and flows over tubes filled with cooling water. The steam cools down and turns into liquid.

The condenser changes steam from turbines into liquid so it can be pumped. Cooler condensers lower steam pressure and improve efficiency. Cooling water flows through the tubes, while steam enters the shell and turns into water. Keeping the condenser cold helps lower steam pressure for better performance. Usually, cooling water makes steam condense at about 77 °F (25 °C). This creates a vacuum of about −28 inHg (−95 kPa) compared to normal air pressure.

This process helps systems work better and transfer heat efficiently.

Applications in Industry

Shell and tube condensers are used in power plants, chemical factories, and oil refineries. They are great for jobs needing strong heat transfer and durability. In power plants, they cool steam from turbines to boost efficiency. In chemical plants, they control heat for sensitive reactions. These condensers handle large amounts of fluid, making them ideal for heavy-duty cooling tasks.

Overview of Plate Heat Exchangers

Design and Structure

A plate heat exchanger has many thin, flat plates stacked together. These plates form small paths for fluids to move through. Each plate has a special design to increase heat transfer. Gaskets or seals are placed between plates to stop leaks and keep fluids apart. You can add or remove plates to change the system's size. This flexible design makes it small and very good at transferring heat.

Functionality and Working Principle

This system works by letting two fluids flow on opposite sides of each plate. One fluid gives off heat, and the other takes it in. The large plate surface allows fast heat transfer. The gaskets keep the fluids from mixing. This system can quickly heat or cool fluids. Its design saves energy, making it a smart choice for many uses.

Tip: Check the gaskets often to avoid leaks and keep it working well.

Applications in Industry

Plate heat exchangers are used in food factories, HVAC systems, and medicine production. In food factories, they heat milk and juices to kill germs. In HVAC systems, they control building temperatures by moving heat between air and water. Their small size and efficiency make them perfect for places with little space and where exact temperature control is needed.

Comparing Shell and Tube Condensers with Plate Heat Exchangers

Heat Exchange Efficiency

Plate heat exchangers are better at transferring heat than shell and tube condensers. Their thin plates and large surface area make them very efficient. Heat moves quickly between fluids, saving energy and working well in many industries.

Shell and tube condensers use tubes to transfer heat. While strong, their design has less surface area for heat transfer. This makes them less efficient compared to plate heat exchangers. In industries needing high efficiency, this difference is important.

Here’s a simple comparison:

Metric | Plate Heat Exchanger | Shell and Tube |

|---|---|---|

⭐⭐⭐⭐☆ | ⭐⭐☆☆☆ | |

Energy efficiency | High | Moderate |

If you need high efficiency, a plate heat exchanger is a better choice.

Space Requirements

Space is important when picking a heat exchanger. Plate heat exchangers are small and fit in tight spaces. Their stacked plates save room while still working well.

Shell and tube condensers need more space. Their round shell and tubes take up a lot of room. This makes them harder to use in small areas.

For example, in small food factories or city HVAC systems, plate heat exchangers are great. But if space isn’t an issue, shell and tube condensers can still work well.

Maintenance and Cleaning

Keeping heat exchangers clean is very important. Plate heat exchangers are easy to clean. You can take them apart, clean the plates, and put them back together quickly. This saves time and keeps them working well.

Shell and tube condensers are harder to clean. You need special tools to clean the tubes, which takes more time. Dirt inside the tubes can lower efficiency, so regular cleaning is needed.

If you want easy maintenance, plate heat exchangers are the best option. They are simple to clean and save effort, especially in places needing frequent upkeep.

Cost Analysis

When picking a heat exchanger, knowing the costs is important. Shell and tube condensers cost more at first. This is because they are strong and made from tough materials. They handle high pressure and heat, which raises their price. But they last a long time and work well in tough jobs, making them worth the money for heavy-duty use.

Plate heat exchangers cost less to buy. Their small size and good heat transfer save on materials and making costs. You can also change their size easily by adding or removing plates. This saves money later, especially for businesses that grow or change.

Maintenance costs are different too. Cleaning shell and tube condensers needs special tools and takes longer. This makes upkeep more expensive. Plate heat exchangers are easier to take apart and clean. This lowers maintenance costs and saves time.

If you want lower costs and easy cleaning, pick a plate heat exchanger. But if you need something strong and long-lasting, a shell and tube condenser is worth the higher price.

Scalability and Flexibility

Being able to grow your system is very important. Plate heat exchangers are great for this. You can add or remove plates to change how much they can handle. This makes them perfect for businesses that might grow or need different heat transfer amounts. You can change the system without buying a new one, saving time and money.

Shell and tube condensers are strong but less flexible. Their design doesn’t allow easy changes. To handle more, you might need a whole new unit. This costs more and takes longer to set up. This makes them less useful for businesses with changing needs.

Plate heat exchangers are also easier to fit in small spaces. They are small and light, so they work well in tight areas. Shell and tube condensers are bigger and need more room. This can be a problem in smaller places.

If you need a system that can grow and fit in small spaces, go with a plate heat exchanger. For steady, large jobs, a shell and tube condenser is a solid choice.

Summary Table of Key Differences

Efficiency, Space, Maintenance, Cost, and Scalability

Here’s a simple comparison of shell and tube condensers and plate heat exchangers:

Characteristic | Shell and Tube Condenser | Plate Heat Exchanger |

|---|---|---|

Efficiency | Transfers heat slower due to smaller surface area. | Transfers heat faster with larger surface area. |

Space Requirements | Needs more room because of its large design. | Small design fits well in tight spaces. |

Maintenance | Cleaning takes time and needs special tools. | Easy to take apart and clean quickly. |

Cost | Costs more upfront but lasts for tough jobs. | Costs less upfront and adjusts easily to changes. |

Scalability | Hard to expand; needs new units for more capacity. | Easy to expand by adding or removing plates. |

This table shows the pros and cons of each type. It helps you decide which one fits your needs best.

Quick Reference for Decision-Making

When picking between these two, think about these points:

If you need high efficiency, go for a plate heat exchanger. Its design moves heat faster and saves energy.

For small spaces, the compact plate heat exchanger is a great choice.

If easy cleaning matters, plate heat exchangers are simple to maintain.

For tough jobs, shell and tube condensers are strong and reliable, even if they cost more.

If you need flexibility, plate heat exchangers can grow with your needs.

Tip: Always think about your specific needs before choosing. The best heat exchanger depends on space, cost, and how you’ll use it.

Recommendations for Choosing the Right Heat Exchanger

Factors to Think About

Picking the right heat exchanger means looking at key points. These include:

Performance Needs: Decide how much heat transfer is required. Plate heat exchangers work fast and efficiently. Shell and tube condensers are better for tough jobs.

Space Limits: Check how much room you have for installation. If space is tight, plate heat exchangers are smaller and fit better.

Maintenance: Think about cleaning needs. Plate heat exchangers are simple to take apart and clean. Shell and tube condensers need more tools and time to clean.

Costs: Compare upfront and long-term costs. Shell and tube condensers cost more but last longer for hard tasks. Plate heat exchangers are cheaper and save money on upkeep.

Growth Options: If your business might expand, pick a system that adjusts. Plate heat exchangers let you add or remove plates easily.

Looking at these points helps you choose the best system for your needs.

Recommendations for Different Uses

Different industries need different heat exchangers. Here’s how to pick the right one:

Industry | Best Heat Exchanger | Why It Works |

|---|---|---|

Power Plants | Shell and Tube Condenser | Handles high heat and pressure, great for cooling turbine steam. |

Food Factories | Plate Heat Exchanger | Small and efficient, perfect for heating milk and juice. |

HVAC Systems | Plate Heat Exchanger | Compact and transfers heat well, ideal for tight spaces. |

Chemical Plants | Shell and Tube Condenser | Strong and reliable for controlling heat in reactions. |

Medicine Production | Plate Heat Exchanger | Precise temperature control and easy cleaning, great for sensitive processes. |

Tip: Think about local rules when choosing. For example, Europe often prefers energy-saving systems because of strict laws.

Choosing based on your industry helps improve efficiency and lower costs.

Knowing how shell and tube condensers differ from plate heat exchangers helps you choose wisely. Shell and tube condensers are strong and handle high pressure well. Plate heat exchangers are small and work more efficiently. Think about space, cleaning, cost, and future needs to pick the best one.

Think about your industry and future plans before deciding. For tough jobs, pick shell and tube condensers. For energy-saving and flexible options, plate heat exchangers are better.

FAQ

What is the main difference between a shell and tube condenser and a plate heat exchanger?

The biggest difference is in their design and efficiency. Shell and tube condensers are bigger and handle high pressure well. Plate heat exchangers are smaller and transfer heat faster because of their large surface area.

Which heat exchanger is better for small spaces?

Plate heat exchangers work best in small spaces. Their small size and stacked plates save space. This makes them great for tight areas like HVAC systems or small factories.

How often should you clean a heat exchanger?

How often you clean depends on use and location. For plate heat exchangers, check and clean them every 6 to 12 months. Shell and tube condensers need cleaning less often but require special tools.

Are plate heat exchangers suitable for high-pressure applications?

Plate heat exchangers are not good for high-pressure jobs. They are made for efficiency and saving space, but they cannot handle as much pressure as shell and tube condensers.

Can you expand a shell and tube condenser?

No, you cannot easily expand a shell and tube condenser. Its design is fixed, so you need a new unit for more capacity. Plate heat exchangers let you add or remove plates to adjust size.

Tip: Talk to an expert to choose the right heat exchanger for your needs.

See Also

A Comprehensive Guide To Air Cooled Condensing Units

An Insight Into Water Chiller Units And Their Function

The Advantages Of CO2 Cascade Refrigeration Units Today