New Trends in Transcritical CO2 Systems for Sustainable Cooling

Transcritical CO2 systems now use less energy and help the environment more. Big companies in data centers and factories pick these systems. They like that these systems have low Global Warming Potential. These systems also follow tough environmental rules. The table below shows how they help:

Energy Efficiency | Sustainability | Adoption |

|---|---|---|

High-efficiency | Low GWP | More companies in many industries use them |

Leaders in every field see clear good points for following rules and helping the planet.

Key Takeaways

Transcritical CO2 systems use less energy and help the environment. Many stores and food factories like to use them.

New ideas like hybrid solar loops help save more energy. Adaptive defrost technology also makes cooling systems work better.

Heat recovery solutions let companies use waste heat again. This lowers energy costs and helps the system work better.

Smart controls and variable speed compressors help the system run well. They lower energy bills and keep temperatures steady.

More places are using transcritical CO2 systems around the world. This is because of new rules and help from governments.

Latest Trends in Transcritical CO2

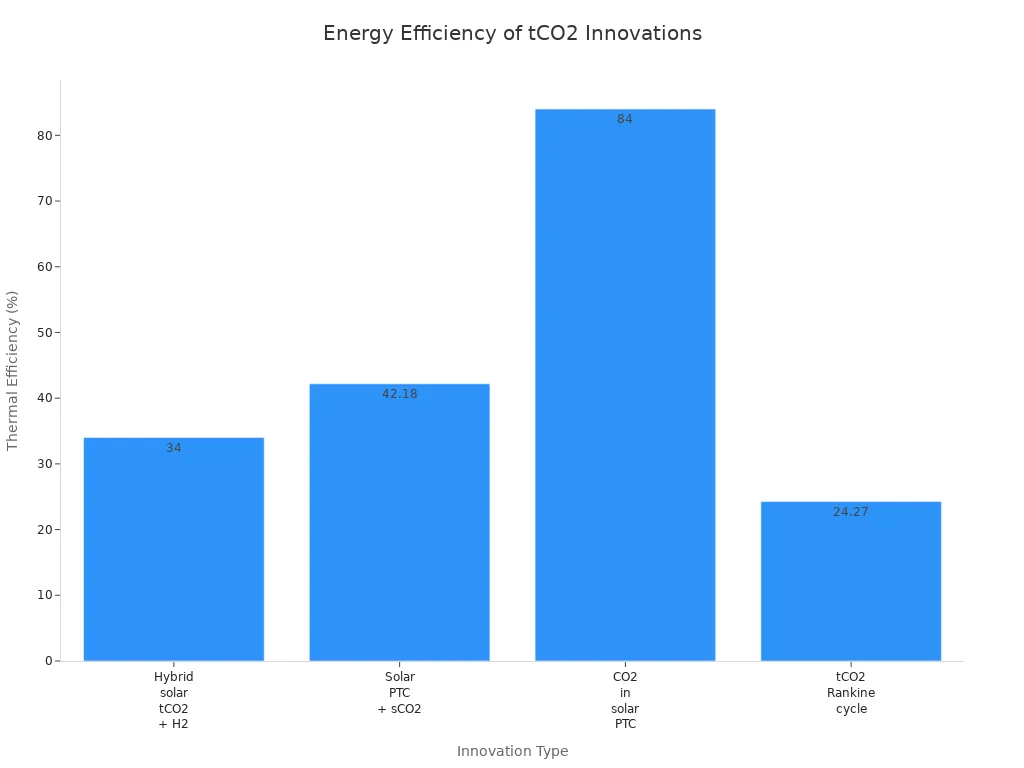

Energy Efficiency Innovations

Engineers are making transcritical CO2 systems use less energy. They try new designs and better materials to make them work better. Some new ideas are hybrid solar transcritical CO2 loops and using green hydrogen. These systems work better and are stronger than old ones.

Innovation Type | Performance Metrics | Key Findings |

|---|---|---|

Hybrid solar transcritical CO2 and green hydrogen loop | Thermal performance: 34%, Cumulative system efficacy: 20% | These systems save more energy than older ones. |

Solar PTC with sCO2 cycle | Peak exergy efficiency: 75.71%, Thermal efficiency: 42.18% | They work very well when the sun is strong. |

CO2 as working fluid in solar PTC | Collector efficiencies: up to 84% | Using CO2 helps turn more energy into power. |

tCO2 Rankine cycle | Solar conversion efficiency: 24.27%, Annual efficiency: 19.80% | These cycles save more energy and money than old ones. |

These changes help companies spend less on energy and make less pollution. Many places now pick transcritical CO2 systems because they cool well and are better for the earth.

Heat Recovery Solutions

Heat recovery in transcritical CO2 systems lets companies use waste heat again. Supermarkets and food plants use this heat for warming rooms and making hot water. This saves energy and lowers bills.

Facilities take heat from the cooling process.

They use the heat to warm up buildings or water.

This makes the whole system work better.

Tip: Heat recovery helps save money and is good for the planet.

When operators use heat recovery with other energy-saving tools, they see great results. These ideas make transcritical CO2 systems a good choice for companies with strict energy rules.

Adaptive Defrost Technology

Adaptive defrost technology helps transcritical CO2 systems work well in all weather. Old defrost cycles waste energy because they run at set times. Adaptive systems use sensors and smart controls to check for frost and only defrost when needed.

Sensors watch the coils for frost.

Controls change defrost times using live data.

This saves energy and stops extra downtime.

Supermarkets and cold storage places like adaptive defrost because it keeps food safe and costs less to run. The technology also helps machines last longer by stopping extra wear.

Industry Adoption of Transcritical CO2

Retail and Food Processing

Retail stores and food factories now pick transcritical CO2 systems for cooling. Supermarkets use these systems to keep food safe and fresh. Food factories need them to control temperatures very closely. These businesses pay less for energy and follow green rules better.

Supermarkets use transcritical CO2 systems to keep food safe.

Food factories use these systems to cut down carbon emissions.

Both groups get steady cooling and help the environment.

A new survey says over 60% of big grocery stores in North America now use transcritical CO2. Many food makers also say they have fewer problems and easier repairs.

Note: Retailers and food makers often get rewards for using green cooling systems.

Logistics and Cold Storage

Logistics companies and cold storage places need strong cooling for goods that spoil. Transcritical CO2 systems help keep things cold during shipping and storage. These systems work well in big warehouses and trucks with fridges.

Sector | Main Benefit | Adoption Rate |

|---|---|---|

Logistics | Steady temperature | Growing |

Cold Storage | Lower energy bills | High |

Logistics workers see fewer spoiled goods and better temperature control. Cold storage places save a lot on power bills. Many companies also follow new rules for climate-friendly work.

Tip: Logistics companies can keep products safer and spend less by using transcritical CO2 systems.

Global Market Expansion

Transcritical CO2 systems now spread to new places around the world. Companies in Latin America and Saudi Arabia buy these systems to follow new green laws. Europe and Asia also use them more because of government rewards.

Latin American stores use transcritical CO2 to follow climate rules.

Saudi Arabian food factories buy these systems to save energy.

Europe and Asia grow fast because of government help.

New rules make companies pick green cooling. Many governments give tax cuts and money to businesses that switch to transcritical CO2. Experts think more places will use these systems as green rules spread.

Callout: More transcritical CO2 systems worldwide help companies reach global green goals.

Tech Advances in Transcritical CO2

Variable Speed Compressors

Variable speed compressors can change their speed to fit cooling needs. This helps the system use less energy when it is not busy. Companies pay less for electricity and their machines last longer. Many places pick these compressors for better control and longer use. They also make less noise and keep the temperature steady. Engineers say these compressors react fast when the cooling load changes.

Tip: Variable speed compressors help save money and keep cooling steady.

Smart Controls Integration

Smart controls use sensors and computer programs to run transcritical CO2 systems. These controls check temperatures, pressures, and energy use all the time. Operators get alerts if something is wrong or needs fixing. Smart controls help systems work well and fix problems faster. They also let people watch and change things from far away. Many companies use smart controls to spend less on repairs and keep workers safe.

Feature | Benefit |

|---|---|

Real-time sensors | Find problems faster |

Remote access | Check systems easily |

Automatic updates | Less work for people |

Smart controls help save energy and follow strict rules.

Modular System Design

Modular system design lets companies build cooling systems in smaller parts. Each part can work alone or with other parts. This makes it easy to add or take away parts when needed. Companies can put in modules quickly and change them for special jobs. Modular systems help cool things closer to where they are needed.

Modular systems are flexible and can grow for big jobs.

They are easy to put in and change for special needs.

Modular designs help with cooling in many places at once.

Operators pick modular design to make their cooling bigger as they grow. It is also easier to fix and upgrade these systems later.

Note: Modular system design helps companies change fast and save money when setting up.

Benefits and Challenges

Sustainability Impact

Transcritical CO2 systems help companies make less pollution. These systems use a refrigerant that does not harm the planet much. Many businesses pick them to reach climate goals and cut greenhouse gases. Operators see cleaner energy and less waste. Some companies get better scores on green checks.

Less carbon released

Less energy wasted

Better ratings for the environment

Note: Many groups use these systems to show they care about the earth.

Operational Efficiency

Operators say transcritical CO2 systems work well in many places. These systems keep temperatures steady and change fast when needed. Maintenance teams fix fewer problems. Many buildings pay less for energy and their machines last longer.

Benefit | Description |

|---|---|

Steady cooling | Keeps food safe and fresh |

Fast response | Changes quickly when needed |

Less downtime | Fewer breakdowns and repairs |

Cold storage managers and store owners see less spoiled food and safer products.

Regulatory and Cost Factors

Governments make strict rules for cooling systems. Transcritical CO2 helps companies follow these rules and not get fined. Many places give tax breaks or money for using green technology. Some businesses pay more at first, but save later with lower bills and fewer fixes.

Follows new climate rules

Gets money or tax breaks

Costs more at first, but saves later

Tip: Companies should look at local rules and rewards before picking a system.

Future Outlook

Emerging Markets

Many places now spend money on better cooling. Latin America and the Middle East are growing fast with transcritical CO2 systems. Companies in Argentina pick these systems to follow new green rules. Food and drink companies, stores, and cold storage want to save energy and help the earth. These groups try to meet climate goals and spend less money. Governments give rewards to use natural refrigerants. As more countries make stricter rules, the market for green cooling grows fast.

Research Directions

Scientists work to make cooling systems smarter and stronger. They look for ways to save more energy and help the planet. Many teams add smart tech like IoT sensors and AI for fixing problems early. These tools help workers stop issues before things break. Scientists also try new cooling ideas like magnetic and thermogalvanic cooling. These new ways can work better and hurt the earth less. The goal is to build systems that use less power and last longer.

Innovation Area | Main Focus | Expected Benefit |

|---|---|---|

Smart technology | IoT, AI for maintenance | Fewer breakdowns |

Alternative cooling | Magnetic, thermogalvanic | Lower energy use |

System efficiency | New designs, better controls | Higher reliability |

Policy Trends

Governments help decide how cooling tech will change. Many countries make tough rules to lower greenhouse gases. Companies must use systems that fit these new rules. Policies help people use natural refrigerants and reward green choices. More people now know that synthetic refrigerants can harm the earth. New tech makes transcritical CO2 systems work better and last longer, so more companies use them.

Note: New rules and rewards help people pick green cooling.

Green rules make companies update their cooling.

More groups want energy-saving systems in important jobs.

Rewards and learning help people use natural refrigerants.

Transcritical CO2 systems are now very important for green cooling. New digital platforms and IoT help companies save more energy. These tools also help them follow strict rules. Many places like hospitals and cold storage see better results with these systems. Businesses can use digital tools to help lower carbon. They can buy eco-friendly refrigeration to save money over time. They can also read reports about natural refrigerants and new tech trends. Learning new things helps every company make good choices for a greener future.

FAQ

What is a transcritical CO2 system?

A transcritical CO2 system cools things using carbon dioxide. It works at higher pressures than normal CO2 systems. This system cools well and follows strict green rules.

Why do companies choose transcritical CO2 systems?

Companies pick these systems because they do not harm the planet much. They help meet climate laws. These systems also save energy and work well.

Where can transcritical CO2 systems be used?

Supermarkets and food factories use these systems to keep things cold. Cold storage places and logistics companies use them too. They are also in trucks and big warehouses.

How do smart controls improve system performance?

Smart controls check temperature and pressure all the time. They send alerts when something needs fixing. Operators can change settings from far away and stop long breaks.

Are transcritical CO2 systems expensive to maintain?

It does not cost too much to keep these systems running. Many people say they break down less often. Saving energy and getting rewards helps pay for the system at first.

See Also

CO2 Refrigeration: An Eco-Friendly Cooling Alternative

Exploring the Benefits of Transcritical CO2 Systems

Innovative Developments in Transcritical Refrigeration: The ARKREF Project

Key Advantages of CO2 Transcritical Refrigeration Systems

Three Cutting-Edge CO2 Transcritical Refrigeration Projects by ARKREF