Tunnel freezer or blast freezer, which saves you money?

You want to save money when choosing a freezing system. In most cases, a blast freezer costs less at the start and uses less energy for small batches. A tunnel freezer suits high-volume operations and can offer better long-term savings for larger businesses. You should weigh upfront costs and running expenses before making your choice.

Key Takeaways

Blast freezers work well for small businesses. They cost less to buy and use less energy. They also need less space and fewer workers to run.

Tunnel freezers are good for big businesses that freeze lots of food each day. They save more money over time but cost more at first. They also need more care and repairs.

Think about your business size and how much you need to freeze. Picking the right freezer can help you save money. It can also help your business work better.

Always look at energy ratings before you buy a freezer. Freezers that use less energy cost less each month. They also keep food safer.

Remember to plan for set-up and repair costs. Blast freezers are easier to install and fix. This makes them a good choice for small businesses.

Upfront Costs

Purchase Price

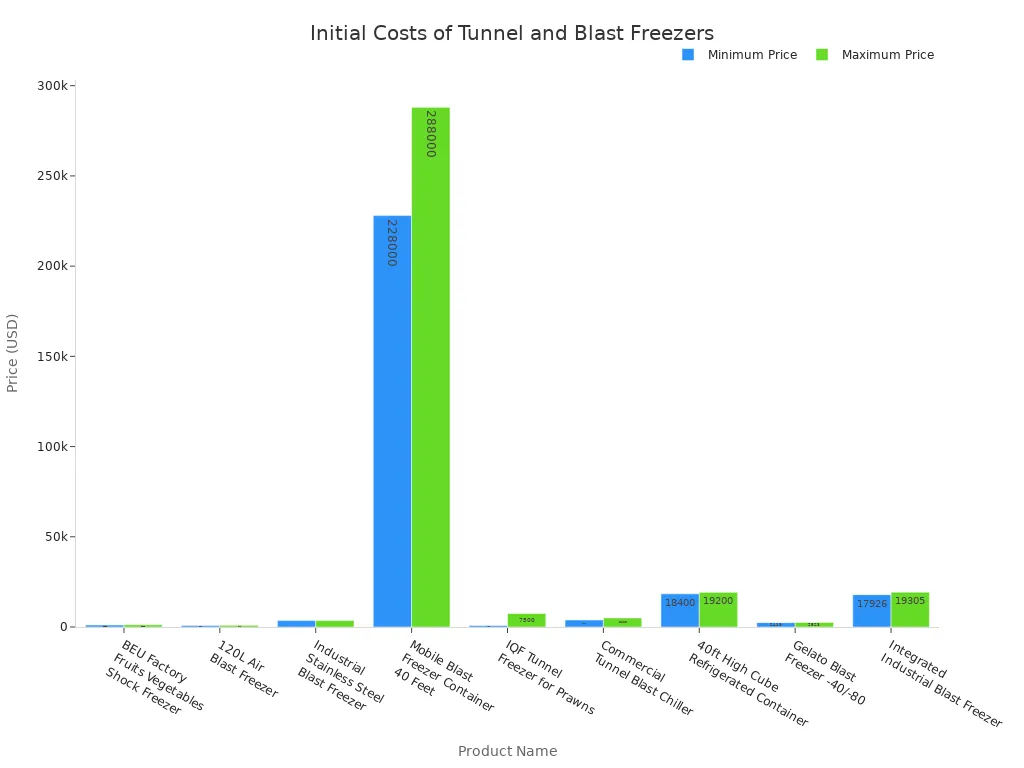

When you look at tunnel freezers and blast freezers, you see many prices. Tunnel freezers usually cost more than blast freezers. The table below shows this price difference.

Product Name | Price Range |

|---|---|

BEU Factory Fruits Vegetables Shock Freezer | $1,102-1,253 |

120L Air Blast Freezer | $850-915 |

Industrial Stainless Steel Blast Freezer | $3,540 |

Mobile Blast Freezer Container 40 Feet | $228,000-288,000 |

IQF Tunnel Freezer for Prawns | $780-7,500 |

Commercial Tunnel Blast Chiller | $3,900-5,000 |

40ft High Cube Refrigerated Container | $18,400-19,200 |

Gelato Blast Freezer -40/-80 | $2,418-2,523 |

Integrated Industrial Blast Freezer | $17,926-19,305 |

Small blast freezers can cost less than $1,000. Big tunnel freezers for factories can cost hundreds of thousands. If you own a small business, blast freezers are cheaper for you.

Installation

You need to think about installation costs. Blast freezers are simple to set up. You can put them in most kitchens or small factories. Tunnel freezers need more room and special setup. You might pay for extra building work or wiring. Large tunnel freezers need expert teams to install them. This makes your starting costs higher.

Tip: To save money on installation, pick a blast freezer for small places. You will not need expensive changes to your building.

Business Size Costs

The size of your business matters. Small businesses save money with cheap blast freezers. Medium businesses may buy bigger blast freezers or small tunnel freezers. Large businesses need tunnel freezers for lots of freezing. The chart below shows how costs go up as freezer size gets bigger.

Tunnel freezers are good for big companies, but they cost much more at first. Blast freezers help you save if you freeze small amounts. Tunnel freezers only save money when you freeze lots every day.

Operating Costs

Energy Use

You need to think about how much energy each freezer uses. Tunnel freezers often run for long hours and freeze large amounts of food at once. This can use a lot of electricity. Blast freezers work well for smaller batches and short cycles. They usually use less energy if you do not freeze much food at a time.

Here is a simple table to help you compare energy use and total running costs:

Freezer Type | Energy Consumption | |

|---|---|---|

Top Freezer Fridge | Lower | Lower |

Bottom Freezer | Higher | Higher |

Tunnel freezers can save you money if you freeze large volumes every day. If you only freeze small batches, blast freezers use less power and cost less to run. You should match your freezer to your daily needs to avoid wasting energy.

💡 Tip: Always check the energy rating before you buy. A more efficient freezer will save you money every month.

Labour Needs

You must also look at how many people you need to run each freezer. Blast freezers are simple. One person can load and unload them. You do not need special training. Tunnel freezers are bigger and more complex. You may need a team to keep them running smoothly. Workers must watch the conveyor belts and check the controls.

If you run a small business, you can save on wages with a blast freezer. Large factories with tunnel freezers often need more staff. This adds to your costs. You should count the number of workers needed before you choose a freezer.

Maintenance

Every freezer needs care to keep working well. Blast freezers have fewer moving parts. You can clean and fix them quickly. Repairs are simple and do not cost much. Tunnel freezers have more parts, like belts and fans. These parts can break or wear out. You may need to call in experts for repairs.

Regular checks and cleaning help both types last longer. Tunnel freezers often need more time and money for maintenance. If you want to keep costs low, blast freezers are easier to look after.

Note: Plan for regular maintenance. This helps you avoid big repair bills and keeps your freezer running well.

In summary:

Blast freezers usually cost less to run for small and medium businesses. They use less energy, need fewer workers, and are easier to maintain. Tunnel freezers can save money for large businesses that freeze a lot of food every day, but they come with higher running costs if you do not use them at full capacity.

Tunnel Freezer Efficiency

Throughput

If you need to freeze lots of food fast, a tunnel freezer is helpful. It can handle many items at once. You put food on a moving belt. Cold air blows over each piece. This makes the food freeze quickly and evenly. Thousands of items can freeze every hour. This helps you fill big orders on time. Your production line does not slow down or get stuck.

Tunnel freezers use individual quick freezing. Each food piece freezes by itself. This stops them from sticking together. Your food stays in better shape and you waste less. You also save time because you do not need to break frozen blocks apart. If your factory is busy, a tunnel freezer keeps things running well.

Technology Benefits

Modern tunnel freezers use smart technology to work better. IoT sensors and data tools help you watch everything in real time. You can see the temperature, humidity, and airflow at each step. This lets you find problems early and fix them fast.

Here is how these features help you:

Evidence Point | Description |

|---|---|

IoT sensors let you check freezer conditions all the time. You can make changes right away and work more efficiently. | |

Better Process Management | Automated controls make things run smoother. You have less downtime and get more done. |

Energy Efficiency | Special heat exchangers help save energy. They make freezing use less power. |

Product Quality Consistency | Watching the process all the time keeps food quality high. Every batch meets your standards. |

Scalability | Small designs mean you can grow your business easily. You do not need to change your building much. |

New insulation materials help too. They can lower energy use by up to 30%. This saves you money and helps you follow food safety rules. Tunnel freezers also stop big ice crystals from forming. This keeps food tasting and feeling good.

Tip: Pick a tunnel freezer with IoT features if you want to save money and keep food quality high. You will have fewer problems and pay less for energy.

Food Quality Impact

Freezing Speed

You want your food to freeze quickly to keep it fresh. Tunnel freezers use a method called Individual Quick Freezing (IQF). This method freezes each piece of food on its own at very low temperatures. You get fast results. The food does not stick together. Blast freezers also work fast, but they freeze batches instead of single pieces. You can freeze small amounts in a short time.

When you freeze food quickly, you stop large ice crystals from forming. Large ice crystals can damage the cells inside the food. If you use a tunnel freezer, you protect the texture and taste. Blast freezers also help, especially with smaller batches. You keep the food safe and tasty.

Tip: Choose a freezer that matches your speed needs. Fast freezing keeps your food in better condition.

Product Texture

You care about how your food feels and looks after freezing. The freezing method changes the texture. IQF in tunnel freezers keeps the texture firm and natural. Each piece stays separate. You do not get mushy or broken food. The flavour and nutrients stay strong.

Blast freezers do a good job with small batches. They freeze food quickly and help keep the structure. If you freeze food slowly, ice crystals grow bigger. These crystals break the protein network in foods like potato gels. You might see changes in texture and structure. Quick freezing stops this problem.

Here is a simple table to show the difference:

Freezer Type | Texture After Freezing | Food Structure | Best For |

|---|---|---|---|

Tunnel (IQF) | Firm, natural | Intact | Fruits, seafood, veg |

Blast | Good, but batch-based | Mostly intact | Meat, baked goods |

You want to keep food quality high. Pick a freezer that freezes fast and keeps the texture strong.

Space & Flexibility

Space Needs

You must think about how much space you have before you choose a freezer. Blast freezers usually take up less room. You can fit them in small kitchens or tight factory spaces. You often find them on wheels, so you can move them if you need to. This makes them a good choice for small businesses or places with limited space.

Tunnel freezers need much more space. They have long conveyor belts and large cooling units. You must plan for a dedicated area in your factory. You cannot move them easily once installed. If you want to expand your freezing line, you may need to change your building layout.

Tip: Measure your available space before you buy. A blast freezer fits well in small areas. A tunnel freezer works best in large factories.

Here is a quick comparison:

Freezer Type | Space Needed | Mobility |

|---|---|---|

Blast Freezer | Small to medium | High |

Tunnel Freezer | Large | Low |

Product Range

You should also think about what foods you want to freeze. Blast freezers work well for many products. You can freeze meat, bread, cakes, and ready meals. You can change the type of food you freeze each day. This gives you flexibility if your menu or product line changes often.

Tunnel freezers suit high-volume, single-product lines. You often see them in seafood, vegetable, or poultry factories. They freeze many pieces quickly, but you may need to adjust settings for different foods. Changing products can take time and may slow down your process.

Blast freezers: Best for businesses with a wide product range or changing menus.

Tunnel freezers: Best for factories that freeze the same product in large amounts.

Note: Flexible freezers help you adapt to new products and market trends. This can save you money in the long run, as you do not need to buy new equipment for every change.

Choosing for Your Business

Small Business

You have a small business. You want to save money and use space well. Blast freezers are a good choice for you. They cost less to buy and set up. You can put them in small places. You do not need many people to run them. Chest and upright freezers help you keep food safe. Chest freezers keep food cold for a long time. Upright freezers let you sort food and get it fast.

Freezer Type | Advantages | Ideal Use Case |

|---|---|---|

Chest Freezers | Great for storing lots of food, save energy, keep temperature steady | Good for storing extra food in the back |

Upright Freezers | Save space, easy to reach food, shelves for sorting, no frost problems | Best for busy kitchens with little room |

Look for freezers that use less energy. These models help you save on bills. Digital controls help you follow food safety rules. You keep your food safe and waste less.

Tip: Pick a small freezer if you do not have much space. You will save money and keep your kitchen tidy.

Medium Business

You run a medium-sized business. You need more freezing power than a small shop. Blast freezers still work well if you freeze many types of food. You can choose bigger models with more shelves. If you freeze one kind of food in large batches, a small tunnel freezer may help. It freezes food faster and keeps texture better.

Think about your space and how much energy you use. Undercounter freezers help you use every bit of space. Smart technology lets you check temperatures on your phone. You keep food safe and work faster.

Operational Factor | Description |

|---|---|

Small freezers like undercounter models help you use space well in small shops. | |

Energy Efficiency | Freezers that use less power help you save money and keep food cold. |

Food Safety | Good freezers with digital controls help you follow health rules and stop food from spoiling. |

Technological Innovations | Smart features let you watch and control your freezer from far away, making work easier. |

Note: Choose a freezer that fits your daily needs. You will spend less and keep your food fresh.

Large Business

You own a big business or factory. You freeze lots of food every day. Tunnel freezers are best for you. They freeze thousands of items quickly. You save time and keep your work moving. These freezers use smart technology. IoT sensors help you watch each step. You keep food quality high and waste less.

Tunnel freezers need more space and cost more at first. You need trained workers to run them. If you use them all the time, you save money later. Plan your space and pick models with good insulation. This helps you pay less for energy.

💡 Tip: Buy a tunnel freezer if you freeze lots of food. You will work faster and save money over time.

You save more money with a blast freezer if you run a small or medium business. Tunnel freezers work best for large factories with high daily output. Use this table to help you decide:

Business Size | Best Freezer Type | Key Benefit |

|---|---|---|

Small/Medium | Blast Freezer | Lower costs, flexible |

Large | Tunnel Freezer | High speed, efficient |

Think about your space, food type, and daily needs before you buy. The right choice helps you save money and keep food quality high.

FAQ

What is the main difference between a tunnel freezer and a blast freezer?

You use a tunnel freezer for high-volume food processing. It freezes food quickly on a conveyor belt. You use a blast freezer and chiller for smaller batches. The blast freezing process works well for flexible food production.

Why should you choose a blast freezer for small businesses?

You save money with a blast freezer and chiller. The blast freezing process uses less energy for small batches. You need less space. You also keep food safe for food safety reasons. The advantages of blast freezing include easy operation and lower costs.

How does blast freezing help with food safety?

You protect food from bacteria with the blast freezing process. You lower the temperature fast. This stops germs from growing. You follow food safety reasons and keep food fresh. You use blast freezer applications in kitchens and food processing plants.

What are the disadvantages of blast freezing?

You may see higher costs if you freeze large amounts of food. The blast freezing process works best for small batches. You need to check the freezer often. The disadvantages of blast freezing include limited capacity for big food processing jobs.

What methods of freezing meat are most effective?

You use effective meat freezing in a blast freezer and chiller. The blast freezing process keeps meat texture firm. You freeze meat quickly for food safety reasons. You use these methods of freezing meat in food processing factories and kitchens.

See Also

Selecting Between Tunnel And Spiral Freezers Effectively

Cost And Efficiency Comparison Of Spiral And Tunnel Freezers

Understanding The Major Advantages Of Tunnel Freezers

Assessing The Competitive Edge Of Tunnel Freezers

Addressing Freezing Challenges With Tunnel Freezer Technology