What Makes a Water-Cooled Chiller Essential for Cooling

Water-cooled chillers are important for keeping businesses running well. They use water to move heat, making them save more energy than air systems. For example, cooling in data centers can use 50% of energy. Water-cooled chillers help cut energy use a lot, especially in busy places like factories or chip-making plants. These chillers keep temperatures steady, even when there’s a lot of heat. As industries need better cooling, the water chiller market is growing and may reach $2.19 billion by 2033.

Key Takeaways

Water-cooled chillers use water to remove heat, saving energy.

They keep temperatures steady, even in hot weather, for industries.

Cleaning pipes and treating water helps them last longer and work well.

These chillers are quieter than air systems, great for quiet places.

Using water-cooled chillers helps the environment by saving energy and cutting pollution.

How a Water-Cooled Chiller Works

Water-cooled chillers are key for cooling systems. They move heat away from spaces or processes. To understand them, we need to look at their parts, the cooling cycle, and how water improves efficiency.

Key Parts of a Water Chiller

A water chiller has important parts that work together. Each part has a job to keep cooling effective. Here's a simple table of the parts and their roles:

Part | Job |

|---|---|

Evaporator | Takes heat from the fluid, cooling it as refrigerant turns to gas. |

Makes refrigerant gas hotter and under pressure before it goes to the condenser. | |

Condenser | Moves heat from refrigerant to water, turning refrigerant back into liquid. |

Cooling Tower | Releases heat from water into the air, finishing the cooling process. |

These parts work as a team to keep temperatures steady. For example, the evaporator cools the fluid, while the cooling tower gets rid of the heat.

The Cooling Cycle and Heat Movement

The cooling cycle is how water chillers work. It repeats steps to absorb, compress, and release heat. Here's the process:

Heat Absorption: The evaporator takes heat from the fluid, turning refrigerant into gas.

Compression: The compressor makes the refrigerant gas hotter and ready to release heat.

Heat Release: The condenser moves heat from refrigerant to water, which goes to the cooling tower.

Expansion: The refrigerant cools down and loses pressure before returning to the evaporator.

This cycle keeps going to maintain cooling. Water is great for this because it moves heat better than air.

Water's Role in Better Cooling

Water helps chillers work efficiently. It moves heat better than air and has many benefits:

Water transfers heat about 200 times better than air. This makes it perfect for cooling places like data centers and factories.

Keeping water at certain temperatures and flow speeds improves cooling. For example, chilled water is often kept at 6 to 7°C for best results.

Liquid cooling is becoming more popular. The market for cooling data centers with liquid may grow from USD 3.52 billion in 2024 to USD 20.95 billion by 2032.

Using water helps chillers cool better and use less energy. This makes them a smart choice for industries needing reliable cooling systems.

Benefits of Water-Cooled Chillers

Energy Efficiency and Cost Savings

Water-cooled chillers save energy and work very efficiently. They use water to move heat, which works better than air. This helps save money, especially in big places like factories. Cooling systems in data centers use a lot of energy. Water-cooled chillers help lower energy use and cut down on bills.

These chillers also work well in hot weather. Unlike air-cooled systems, they stay steady even when it’s hot outside. This makes them great for places with warm climates. Using less energy not only saves money but also helps the environment.

Durability and Long-Term Performance

Water-cooled chillers are strong and last a long time. They are made with advanced designs to work well for years. Modern systems use smart tools to check for problems early. These tools can find issues like rust or dirt buildup before they get worse.

You can keep your chiller working longer with special treatments. These treatments stop rust, dirt, and germs from causing damage. With good care, water-cooled chillers can work well for many years. This makes them a good choice for long-term use.

Things that help them last longer include:

Smart cooling methods to improve how they work.

Tools that find problems early using smart technology.

Treatments to stop rust and dirt from building up.

Environmental Advantages and Quiet Operation

Water-cooled chillers are better for the planet. They use less energy than air-cooled systems, which lowers pollution. Their heat-moving process also uses fewer natural resources. By using water, these chillers help create a greener future.

They are also quieter than air-cooled systems. Air-cooled chillers use big fans that make noise. Water-cooled chillers use water to cool, which is much quieter. This makes them perfect for quiet places like hospitals, schools, or offices. With these chillers, you get great cooling without loud sounds.

Applications of Water-Cooled Chillers

Water-cooled chillers are important for many industries. They help keep systems and processes cool and working well. Let’s look at how they are used in factories, businesses, and special fields.

Industrial Uses (Manufacturing, Chemical Processing)

Factories need water-cooled chillers to keep machines from overheating. Power plants use them to remove extra heat, especially in nuclear and fossil fuel facilities. Chemical plants and refineries rely on chillers to cool liquids and tools. Steel factories use them to handle heat from furnaces and rolling machines.

Industry | What They Do |

|---|---|

Power Plants | Take away extra heat from making energy. |

Chemical Factories | Cool liquids, tools, and machines during production. |

Steel Factories | Control heat from furnaces and rolling machines. |

Commercial Applications (HVAC, Data Centers)

Big buildings like hospitals and malls use water chillers for air conditioning. They cool large spaces efficiently. Data centers also use these chillers to save energy and protect equipment. They can cut energy use by 40%, making systems last longer and lowering repair costs.

Benefit | How It Helps |

|---|---|

Energy Savings | Cuts energy use by up to 40%. |

Equipment Protection | Makes machines last longer. |

Lower Costs | Reduces repair and upkeep costs. |

Specialized Applications (Medical, Food Processing)

Hospitals use water chillers to keep imaging tools and surgery rooms cool. Food factories use them to cool machines and remove heat during production. This helps keep food safe and high-quality.

💡 Tip: Using water chillers in these areas improves performance and meets safety rules.

Water-Cooled Chillers vs. Air-Cooled Chillers

Efficiency in High-Temperature Environments

Water-cooled chillers work well in hot weather. They use water to move heat, staying efficient even when it’s warm outside. Air-cooled chillers use air to cool, but they don’t work as well in heat. In very hot places, water-cooled chillers keep cooling steady, while air-cooled systems may struggle.

Water is great at absorbing and moving heat. This makes it perfect for cooling big areas or machines. Factories in warm places often pick water-cooled chillers for reliable cooling. If you need steady cooling in hot weather, water-cooled chillers are a smart choice.

Space and Installation Considerations

Water-cooled chillers need more room but can be placed indoors. You can put them in basements or maintenance rooms, keeping them safe from bad weather. Air-cooled chillers need outdoor space for airflow.

Here’s how water-cooled chillers fit different spaces:

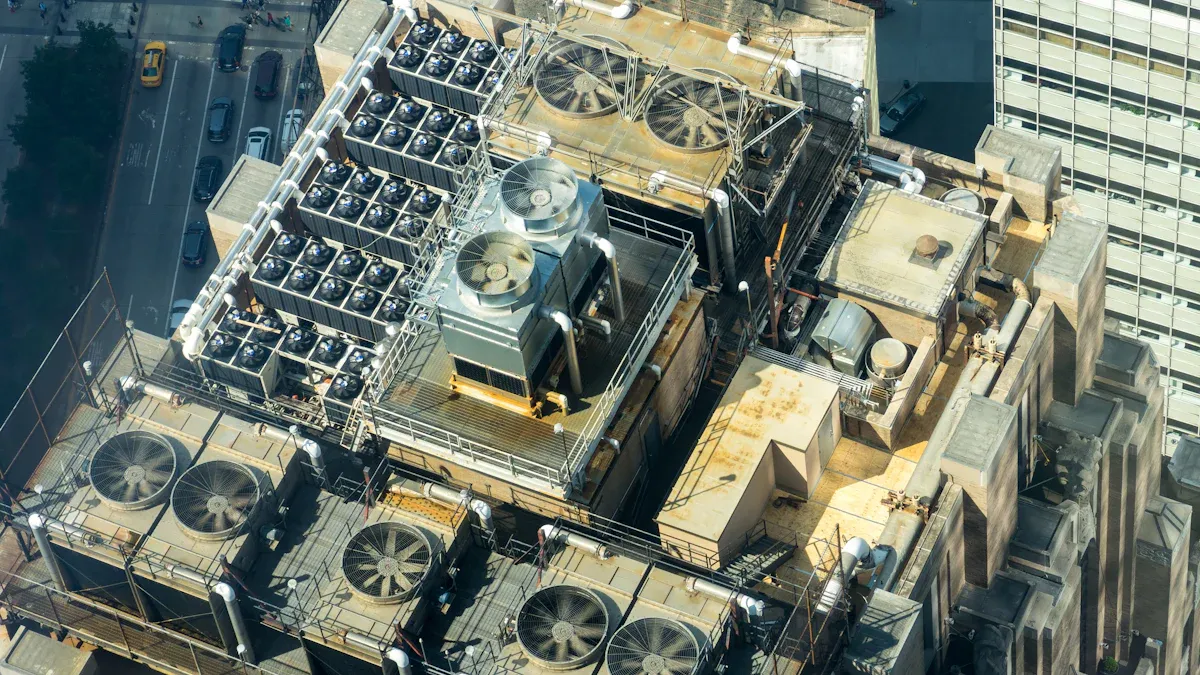

A building’s basement has a water-cooled chiller linked to a boiler. Heat moves through pipes to cooling towers on the roof.

A school uses a water-cooled chiller in a maintenance room. It works well with HVAC systems and saves space.

If you don’t have much outdoor space, water-cooled chillers are a good option for indoor setups.

Maintenance and Longevity Comparison

Water-cooled chillers last longer because they stay indoors. This protects them from weather damage. Cleaning pipes and treating water stops rust and keeps them working well for years.

Air-cooled chillers need less care but are outside, where dirt can cause problems. This can make them wear out faster. If you want a system that lasts a long time, water-cooled chillers are worth the investment.

💡 Tip: Take care of water-cooled chillers regularly to keep them efficient and lasting longer.

Water-cooled chillers are important for today’s cooling needs. They save energy, work reliably, and can be used in many ways. More people are using liquid cooling for powerful servers and AI tasks. These systems also help the planet by lowering harm to the environment.

Evidence Type | Description |

|---|---|

Growing Use | More liquid cooling is used for servers and AI tasks. |

Better Efficiency | Liquid cooling removes heat well, saving more energy. |

Eco-Friendly Need | Data centers are pushed to use greener cooling methods. |

Picking a water chiller means great cooling and helping the environment.

FAQ

What is the main difference between water-cooled and air-cooled chillers?

Water-cooled chillers use water to move heat, while air-cooled ones use air. Water-cooled systems work better in hot places and are quieter. Air-cooled systems need less care and are easier to set up outside.

How do you maintain a water-cooled chiller?

You need to clean pipes and treat water to stop rust. Check for dirt often to keep it working well. Smart tools can find problems early. Taking care of it helps it last longer and work better.

💡 Tip: Plan regular checkups to avoid big repair costs.

Are water-cooled chillers environmentally friendly?

Yes, they use less energy than air-cooled systems. They move heat efficiently, which saves energy and lowers pollution. This makes them a better choice for the environment.

Can water-cooled chillers be used in small spaces?

Yes, they can be placed indoors, like in basements or utility rooms. They don’t need outdoor airflow like air-cooled systems. This makes them good for buildings with little outdoor space.

Why are water-cooled chillers quieter than air-cooled ones?

Water-cooled chillers don’t use big fans to cool. They use water, which is much quieter. This makes them great for quiet places like schools or hospitals.

🔇 Note: If you need less noise, pick water-cooled chillers.

See Also

Choosing The Right Industrial Water Chiller Units Effectively

Exploring The Advantages Of CO₂ Transcritical Refrigeration Systems

Three Key Advantages Of CO₂ Refrigeration Over Traditional Methods

Introduction To ARKREF CO₂ Transcritical Refrigeration Unit Applications