Water Chillers Explained: What They Are and How They Work

A water chiller is a machine that cools water by removing heat. It is used in many industries like HVAC and manufacturing. These industries need to control temperatures very carefully. Over time, better technology has changed how cooling is done:

Water-cooled chillers made up 45.2% of the Asia Pacific market in 2024 because they save energy.

Centrifugal chillers held 35.7% of the market and are great for big operations.

The petrochemical industry used 28.7% of chillers due to growing factories.

Chilled water from these machines is used in air conditioning, cooling factories, and chemical work.

Key Takeaways

Water chillers make water cold by taking away heat. They are important for HVAC systems and factories.

You can pick air-cooled or water-cooled chillers. Air-cooled ones are simpler to care for, but water-cooled ones work better.

Taking care of chillers, like cleaning parts and checking refrigerant, helps them work well and last longer.

Knowing how the cooling process works helps you understand chillers better.

Chilled water saves energy and works well in big spaces and factories.

What Is a Water Chiller?

Definition and Purpose

A water chiller is a machine that cools water. It works by taking heat out of the water. Think of it as the main part of a cooling system. It moves cold water through pipes, called the chilled water loop. This helps control temperatures in buildings, factories, and other places.

The main job of a chiller is to keep temperatures steady. This is very important for systems that need exact cooling. For example, air conditioning in big buildings or machines that get hot during work. A water chiller helps these systems run smoothly and reliably.

Importance of Chilled Water in Cooling Systems

Chilled water is very important in cooling systems. It carries heat away from areas or machines that need cooling. The chilled water loop moves water between the chiller and the places needing temperature control. This keeps the system working well and removes heat quickly.

Using chilled water makes cooling systems work better. It cools large spaces or machines without using too much energy. For example, in HVAC systems, chilled water keeps rooms cool and saves energy. In factories, it stops machines from getting too hot, helping them work properly.

The system's efficiency depends on how well the chiller works. A good chiller keeps the chilled water loop running at its best. This reduces wasted energy and improves cooling. By choosing a good water chiller, you can save money and make your cooling system better.

Types of Water Chillers

Water chillers come in various kinds for different cooling needs. Knowing these types helps you pick the right one.

Air-Cooled Chillers

Air-cooled chillers use air to cool the system. They are easy to set up and maintain. These chillers don’t need a cooling tower, so they work well in places with little water. They are often used in small spaces or for temporary cooling, like labs.

Air-cooled chillers are simple and need less upkeep. But they use more energy and need more space for airflow. If you want something easy to move and maintain, this type is a good choice.

Water-Cooled Chillers

Water-cooled chillers use water to cool, making them more efficient. They are common in industries with high cooling needs. These chillers need a cooling tower, which costs more to install but saves energy over time.

Water-cooled chillers are great for steady and strong cooling. They last longer than air-cooled chillers. If you need a dependable system for big jobs, this type works well.

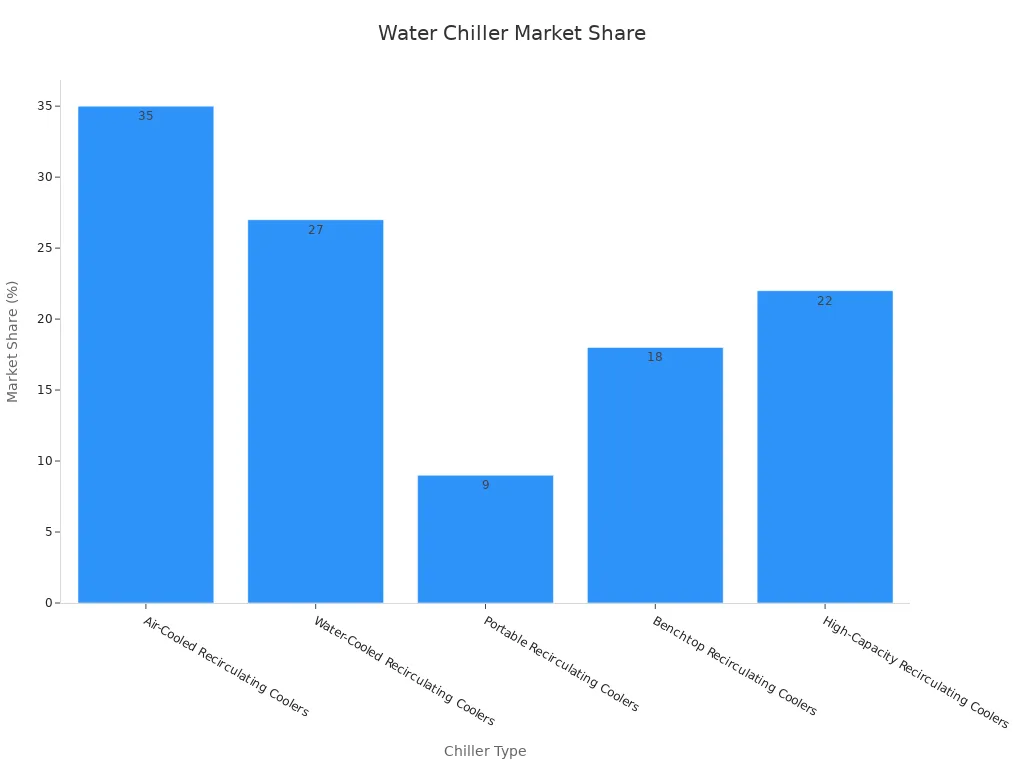

Type of Water Chiller | Market Share (%) | Key Features |

|---|---|---|

Air-Cooled Recirculating Coolers | 35% | Easy to install, low upkeep, good for mobile labs. |

Water-Cooled Recirculating Coolers | 27% | High efficiency, best for industries, saves energy long-term. |

Portable Recirculating Coolers | 9% | Small size, easy to move, great for fieldwork and research. |

Benchtop Recirculating Coolers | 18% | Quiet, precise cooling for labs, good for sensitive tasks. |

High-Capacity Recirculating Coolers | 22% | Handles high flow, built for tough industrial jobs, strong cooling. |

Comparing Air-Cooled and Water-Cooled Chillers

When choosing between air-cooled and water-cooled chillers, think about efficiency, upkeep, and space. Water-cooled chillers cool better and last longer but need more care and a cooling tower. Air-cooled chillers are easier to care for but use more space and energy.

Chiller Type | Efficiency | Maintenance Needs | Lifespan | Space Requirements |

|---|---|---|---|---|

Water-Cooled | Needs more care | Lasts longer | Needs cooling tower | |

Air-Cooled | Less efficient | Easier to maintain | Shorter lifespan | Needs more space |

By learning these differences, you can choose the best chiller for your needs.

How Chillers Work

Knowing how chillers work helps you understand their cooling job. These machines use a process called the refrigeration cycle to cool water. This cycle removes heat from water and makes it cold. Let’s look at the steps.

The Refrigeration Cycle

The refrigeration cycle is the main process in chillers. It moves heat from one place to another. In a chiller, it takes heat from water and releases it outside. A special fluid called refrigerant does this job. It absorbs and releases heat as it changes between liquid and gas.

Here’s how the cycle works:

The refrigerant takes heat from water in the evaporator.

It goes to the compressor, where it gets pressurized.

The refrigerant releases heat in the condenser.

It cools down in the expansion valve and starts again.

This process keeps repeating, so the water stays cold for your system.

Tip: Think of the cycle as a heat mover. It takes heat from water and sends it away, leaving cold water behind.

Key Stages: Evaporation, Compression, Condensation, Expansion

The refrigeration cycle has four main stages. Each stage is important for how chillers work. Here’s a simple breakdown:

Evaporation:

The refrigerant absorbs heat from water in the evaporator. Water flows over coils with refrigerant, losing its heat. The refrigerant turns into gas, cooling the water.Compression:

The refrigerant gas moves to the compressor. It gets pressurized, making it hotter. This step prepares it to release heat next.Condensation:

The hot refrigerant enters the condenser. It releases heat into air (air-cooled chillers) or water (water-cooled chillers). The refrigerant cools down and becomes liquid again.Expansion:

The liquid refrigerant passes through the expansion valve. Its pressure and temperature drop, making it cold. It’s now ready to absorb heat again.

These stages work together to keep the chiller running well. Understanding them helps you see how chillers cool water.

How Heat Is Removed from Water

The main job of a chiller is to remove heat from water. This happens in the evaporator. The refrigerant absorbs heat from water flowing over its coils. The water cools down and becomes chilled water.

The chilled water moves through your system, cooling spaces or machines. After absorbing heat, the water returns to the chiller to cool again. This loop keeps your system cool and working efficiently.

Note: A well-kept chiller works better and saves energy. Regular maintenance ensures the cooling process stays effective.

Key Components of a Water Chiller

Compressor

The compressor is like the engine of a chiller. It squeezes the refrigerant, turning it into hot gas. This step gets the refrigerant ready to release heat later. Compressors come in types like screw, scroll, and centrifugal. Centrifugal ones are great for big jobs because they save energy.

A good compressor keeps the chiller working well. It helps the system stay efficient. Regular care, like fixing leaks or worn parts, is important. This makes the chiller last longer and work better.

Evaporator

The evaporator is where cooling happens. It takes heat from water, making it cold. Water flows over coils filled with refrigerant inside the evaporator. The refrigerant soaks up the heat, leaving chilled water behind.

Evaporators are great at moving heat. They help in many places:

Factories stop machines from overheating.

Big buildings lower power bills by cooling air systems.

Labs and hospitals get steady cooling with less energy.

A good evaporator saves money and helps the planet. It also protects your system from wearing out too fast.

Condenser

The condenser gets rid of the heat the refrigerant absorbs. It moves this heat to air or water, depending on the chiller type. Air-cooled chillers use fans to push heat into the air. Water-cooled chillers use cooling towers to do the job.

A clean condenser keeps the chiller running well. It stops overheating and keeps things stable. Cleaning dirt and dust off the condenser helps heat move out faster. This simple task makes your cooling system work better.

Tip: Clean the condenser often to save energy and avoid problems.

Expansion Valve

The expansion valve is very important in a chiller. It controls how much refrigerant goes into the evaporator. By lowering the refrigerant's pressure, it also lowers its temperature. This makes the refrigerant ready to take heat from the water. This step helps the system cool water properly.

Think of the expansion valve as a traffic light. It decides how much refrigerant can enter the evaporator at a time. If too much enters, the system won’t cool well. If too little enters, the cooling power drops. The valve keeps the system working efficiently.

There are different kinds of expansion valves. Thermostatic valves adjust based on temperature. Electronic valves use sensors for better control. The right valve depends on what your system needs.

Tip: Check the expansion valve often for clogs or damage. A broken valve can mess up the cooling process.

Supporting Components and Their Roles

A chiller needs other parts to work smoothly. These parts help the system cool and run well.

Pumps: Pumps move water through the system. They send cold water to cool areas and bring warm water back to the chiller.

Cooling Tower: In water-cooled chillers, the cooling tower removes heat. It uses air and water to cool the refrigerant in the condenser.

Control Panel: The control panel is like the chiller’s brain. It watches and adjusts how the system works. New panels have screens and sensors for better control.

Filters: Filters keep the system clean. They stop dirt from blocking parts, which keeps the system efficient.

Piping System: Pipes connect all the parts of the chiller. They carry water and refrigerant to keep everything running.

Each part is important for the chiller to work well. Taking care of these parts can make the system last longer and work better.

Note: Regular care of these parts can stop big problems and keep cooling steady.

Applications of Water Chillers

Water chillers are important in many industries and systems. They help with cooling and keeping temperatures steady, making them very useful.

Use in HVAC Systems

Water chillers are used in HVAC systems to cool big spaces. These include offices, malls, and hospitals. Chilled water flows through air handlers or fan coils. It absorbs heat from the air, keeping rooms cool. This also lowers humidity, improving air quality.

Water chillers are great for places needing strong cooling. They keep temperatures steady for comfort. Using chilled water helps HVAC systems save energy and cut costs. Taking care of the chiller keeps it working well and lasting longer.

Industrial and Manufacturing Applications

Factories and industries use water chillers to cool machines and processes. They stop equipment from overheating, which can cause damage or delays. Industries like plastics, medicine, and food rely on chilled water to work smoothly.

For example, in plastic molding, chilled water cools molds faster. This speeds up production. In medicine, it keeps strict temperatures during manufacturing. A good chiller boosts productivity and protects machines from wearing out.

Integration with Cooling Towers

Water chillers and cooling towers work together in factories. Cooling towers help water-cooled chillers remove heat. This teamwork has many benefits:

Modular designs let you grow your system easily.

Eco-friendly options help meet green goals.

This setup adjusts to your needs while staying efficient. Using both a chiller and cooling tower gives you a cost-saving and eco-friendly cooling system.

Water chillers are important for today’s cooling systems. They keep temperatures steady, which is crucial for HVAC, factories, and industries. These machines save energy while providing dependable cooling. They can be used in many places, from small labs to big factories. To get the most out of a chiller, learn more or ask experts for advice. This helps you pick the right system for your needs.

FAQ

What is the difference between a water chiller and an air conditioner?

A water chiller cools water, which then cools spaces or machines. An air conditioner cools air directly. Chillers are best for big cooling jobs. Air conditioners are better for homes or small offices.

How do I choose between air-cooled and water-cooled chillers?

Pick based on your needs. Air-cooled chillers are good where water is scarce. Water-cooled chillers are more efficient for big cooling but need a cooling tower.

How often should I maintain my water chiller?

Check your chiller every three months. Clean the condenser and check refrigerant levels. Make sure pumps and filters work well. Regular care keeps it efficient and lasting longer.

Can water chillers save energy?

Yes! Water chillers, especially water-cooled ones, use less energy for big cooling. Using cooling towers or energy-saving parts can lower energy costs even more.

Are water chillers eco-friendly?

Water chillers can be eco-friendly with energy-saving designs and green refrigerants. Regular care reduces energy waste, making them a good choice for the environment.

Tip: Ask an expert to find a chiller that saves energy and helps the planet.

See Also

A Comprehensive Guide To Water Chiller Unit Functionality

Proven Strategies To Enhance Walk-In Chiller Performance

Exploring The Purpose And Use Of Cold Rooms

Key Differences Between Cold Rooms And Cool Rooms

Maximizing Efficiency Of Chillers And Compressors In ARKREF Units